NinjaTek Armadillo Settings

Hi, can anyone give me advice on printing with Ninjatek Armadillo, I have 12 hour solid fill print to do when I get the Armadillo delivered.

I have a PRUSA MK3s

Thanks

RE: NinjaTek Armadillo Settings

Hi

Maybe it will be more than 12 hours... 🤔

I'm working with it since a while, first on a CR10 and now mainly on my MK3S.

It's a difficult material, prone to ooze, difficult at overhangs, maybe better in an enclosure (next project for my MK3S).

It's a tough material and i use it for automotive parts.

Extruder temp has to be very precise and in my case it's above recommended temp : 239°

But, my extruder temp is not calibrated with an external thermometer so i can't say if it's really way above.

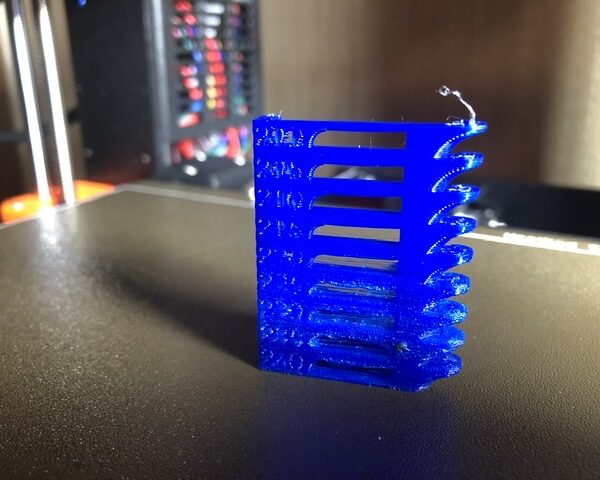

Use a temp tower to set your temp, i use this one with details, bridging and overhangs.

I don't bother with the numbers to print, they are just there to test detail printing.

To set the temp changes, i use the "insert a customized GCODE" feature of prusaslicer 2.2.0 to set temp changes (M109 S(your temp)) instead of changing it in the printer "before layer change" GCODE.

2° step change temp are useful for Armadillo to find the right temp.

I use very slow speed 10-15 mm/s or rather than setting a speed, i limit the volumetric speed at 0.8-1 mm3/s for detailed parts but it can be more for non detailled parts.

I don't use retraction with a good linear advance setting of 0.15

I don't use fan cooling.

This is my experience and i will be pleased to exchange with you about yours with this material.

RE: NinjaTek Armadillo Settings

Hi

Maybe it will be more than 12 hours... 🤔

I'm working with it since a while, first on a CR10 and now mainly on my MK3S.

It's a difficult material, prone to ooze, difficult at overhangs, maybe better in an enclosure (next project for my MK3S).

It's a tough material and i use it for automotive parts.

Extruder temp has to be very precise and in my case it's above recommended temp : 239°

But, my extruder temp is not calibrated with an external thermometer so i can't say if it's really way above.

Use a temp tower to set your temp, i use this one with details, bridging and overhangs.

I don't bother with the numbers to print, they are just there to test detail printing.

To set the temp changes, i use the "insert a customized GCODE" feature of prusaslicer 2.2.0 to set temp changes (M109 S(your temp)) instead of changing it in the printer "before layer change" GCODE.2° step change temp are useful for Armadillo to find the right temp.

I use very slow speed 10-15 mm/s or rather than setting a speed, i limit the volumetric speed at 0.8-1 mm3/s for detailed parts but it can be more for non detailled parts.

I don't use retraction with a good linear advance setting of 0.15

I don't use fan cooling.

This is my experience and i will be pleased to exchange with you about yours with this material.

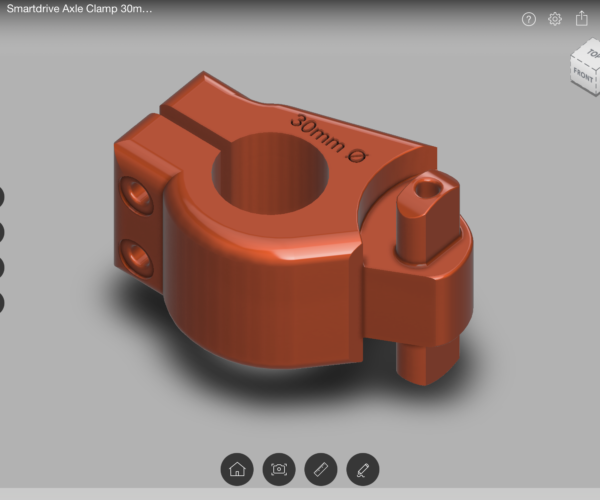

This is the Fusion 360 Model, the main streets bearing part is the 2 lugs with the 6mm hole which I’ll strengthen with a piece of 6 mm stainless. I’ll need support material for the large 30mm hole and the 2 lugs.

I Plan to do a test print cutting the left side away and see how the 2 lugs will print. I also plan to use a 6mm nozzle.

Your advice will be a big help, thank you.

RE: NinjaTek Armadillo Settings

Hi

Maybe it will be more than 12 hours... 🤔

I'm working with it since a while, first on a CR10 and now mainly on my MK3S.

It's a difficult material, prone to ooze, difficult at overhangs, maybe better in an enclosure (next project for my MK3S).

It's a tough material and i use it for automotive parts.

Extruder temp has to be very precise and in my case it's above recommended temp : 239°

But, my extruder temp is not calibrated with an external thermometer so i can't say if it's really way above.

Use a temp tower to set your temp, i use this one with details, bridging and overhangs.

I don't bother with the numbers to print, they are just there to test detail printing.

To set the temp changes, i use the "insert a customized GCODE" feature of prusaslicer 2.2.0 to set temp changes (M109 S(your temp)) instead of changing it in the printer "before layer change" GCODE.2° step change temp are useful for Armadillo to find the right temp.

I use very slow speed 10-15 mm/s or rather than setting a speed, i limit the volumetric speed at 0.8-1 mm3/s for detailed parts but it can be more for non detailled parts.

I don't use retraction with a good linear advance setting of 0.15

I don't use fan cooling.

This is my experience and i will be pleased to exchange with you about yours with this material.

This is the Fusion 360 Model, the main streets bearing part is the 2 lugs with the 6mm hole which I’ll strengthen with a piece of 6 mm stainless. I’ll need support material for the large 30mm hole and the 2 lugs.

I Plan to do a test print cutting the left side away and see how the 2 lugs will print. I also plan to use a 6mm nozzle.Your advice will be a big help, thank you.

*stress bearing

RE: NinjaTek Armadillo Settings

AMHA, too much support to print with a 80$/kg filament.

Find a solution to minimize support, reonrient your part or draw support structure yourself in f360.

RE: NinjaTek Armadillo Settings

AMHA, too much support to print with a 80$/kg filament.

Find a solution to minimize support, reonrient your part or draw support structure yourself in f360.

I guess I could add a ledge underneath the lugs then extrude upwards with thin extrusions if you know what I mean, could do the same with the 30mm hole.? I’m new to this 3D Printing so customer stuff like this is not obvious.

thanks

RE: NinjaTek Armadillo Settings

More than a matter of price, you have to draw your parts for the production tool you use.

Sometimes you have to think twice to avoid overhangs in general and so supports, rafts, ...

Specially for the Ninjatek filaments or TPU in general, TPU is very sticky to himself, support or sacrificial layers are very difficult to remove or let you with a poor surface finish.

Sometimes it is better to split your final part in multiple prints you fit together with alignement pins and glue. There are structural PU glues.

It seems that you draw filleted corners everywhere and filleted corners are not very nice when perpendicular to Z, chamfer are nicer.

Last thing i think for now, Armadillo is really not very sticky to the textured surface plate we have on the MK3S, quite the contrary, i have Lockbuild on my CR10 and it sticks too much.

RE: NinjaTek Armadillo Settings

More than a matter of price, you have to draw your parts for the production tool you use.

Sometimes you have to think twice to avoid overhangs in general and so supports, rafts, ...

Specially for the Ninjatek filaments or TPU in general, TPU is very sticky to himself, support or sacrificial layers are very difficult to remove or let you with a poor surface finish.

Sometimes it is better to split your final part in multiple prints you fit together with alignement pins and glue. There are structural PU glues.

It seems that you draw filleted corners everywhere and filleted corners are not very nice when perpendicular to Z, chamfer are nicer.

Last thing i think for now, Armadillo is really not very sticky to the textured surface plate we have on the MK3S, quite the contrary, i have Lockbuild on my CR10 and it sticks too much.

I’ve only got a couple of parts to print, main thing is they need to be strong so the quality of the print isn’t important. I’ll do a test print slicing the top part then see how it roles. Here’s a link to a YouTube vid of what it’s all about.

as you see the original clamps are plastic, maybe ABS Moulded? My problem with the original clamps the clamping does hold the clamp secure, eventually it moves around the axle so making a custom part will give better grip having a 30mm hole clamping round a 30mm Axle. An alternative option if this doesn’t work is to make some space the exact size or just keep adjusting it like the guy does in the vid.

RE: NinjaTek Armadillo Settings

@delamarre-frederic

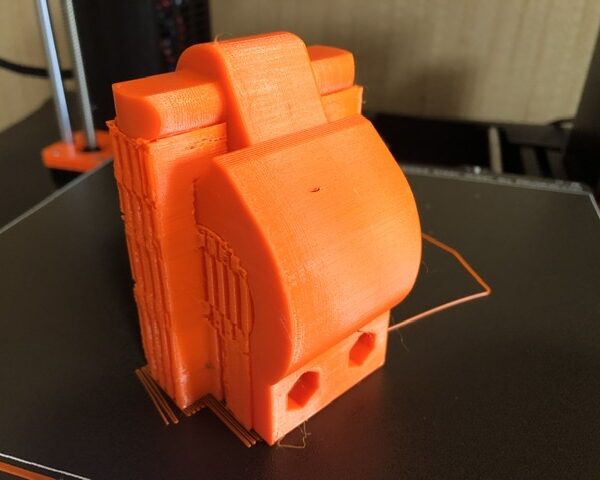

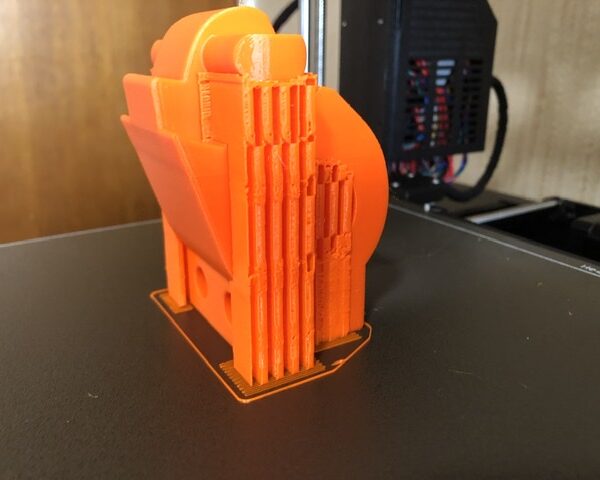

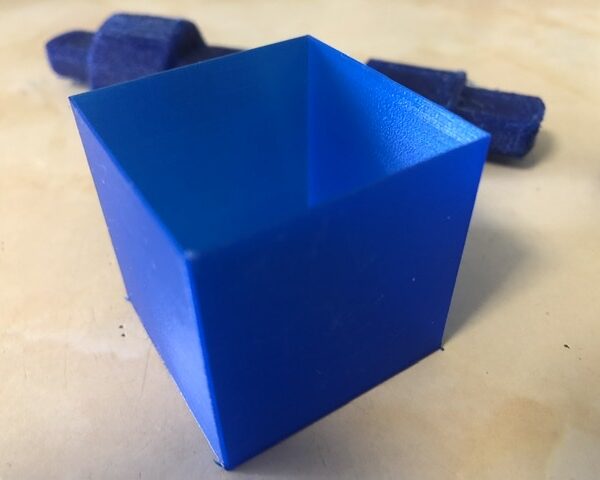

The test went well, doesn't look great but its unbelievably strong. I couldn't break the lugs, I managed to bend then sprang back in shape. This is going to be perfect.

The downside is it's not dimensionally accurate, the lugs are oversized by about .5mm, the 6mm hole is 5.2mm, actually, I'm not sure if I even need to drive a 6mm pin through the part for strength ? I've got to think how I'm going to deal with the 30mm hole, maybe increase size by about 0.5mm .

The support material came off really easily.

Cheers

RE: NinjaTek Armadillo Settings

Yes Armadillo is a very strong material.

Dimensionnal accuracy can be improved, with a good extrusion multiplier at the right temp.

Cheers to your satisfaction. 🍷

In return, one of my parts in black armadillo :

RE: NinjaTek Armadillo Settings

@delamarre-frederic

thanks I’ll give this a try

https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257/

RE: NinjaTek Armadillo Settings

@delamarre-frederic

what multiplier valour do you use as a matter of interest?

RE: NinjaTek Armadillo Settings

1.03 for me, but many parameters (including this one) are machine dependant.

RE: NinjaTek Armadillo Settings

@delamarre-frederic

i’ve done a few tests, it seems the first 3mm of prints on all 3 samples is good then the quality, roughness steadily gets worse all the way up to top layer. I printed the multiplier calibration box and came out brilliant.

RE: NinjaTek Armadillo Settings

100% filled parts needs a very precise extruded quantity of plastic.

Overextrusion has little effect on a single wall part but not on a solid part, overhangs, top surface finish...

I told you armadillo can be difficult to tune, slow the speed (15mm/s), adjust the correct temp (temp tower), adjust extrusion multiplier, adjust linear advance.

Try to have consistant results on multiple iterrations of the same test (temp tower, extrusion multiplier test cube, linear advance marlin test...)

RE: NinjaTek Armadillo Settings

@delamarre-frederic

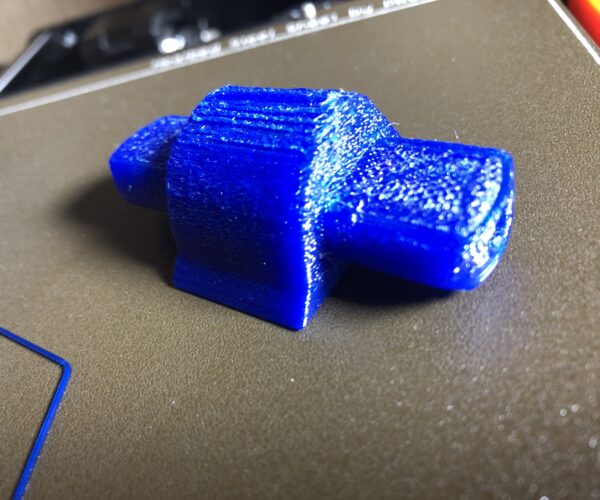

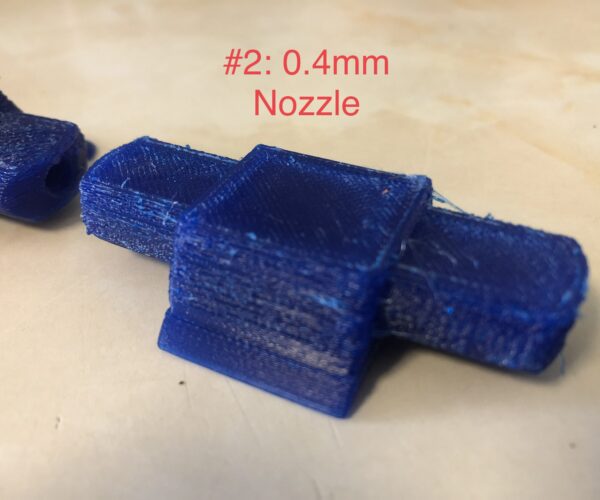

Heres the print, for some reason its was one step out so 235c is 240c to me the 215c in photo =220c real looks the best. I set max vol to 1mm 3/s. The pint was very slow. .7 nozzle, 0.3mm layer height, fans to 100%.

{if layer_z == 6.2}M104 S240{endif};

{if layer_z == 11.3}M104 S235{endif};

{if layer_z == 16.40}M104 S230{endif};

{if layer_z == 21.20}M104 S225{endif};

{if layer_z == 26.3}M104 S220{endif};

{if layer_z == 31.4}M104 S215{endif};

{if layer_z == 36.2}M104 S210{endif};

{if layer_z == 41.3}M104 S205{endif};

{if layer_z == 44.9}M104 S200{endif};

RE: NinjaTek Armadillo Settings

Try without cooling, temp is the first paramete, cooling is just for speeding up things.

Or maybe i'm wrong...