Model dimensions don't match slicer

I am using PrusaSlicer 2.1.1 + Win64

I am printing with the Galaxy Silver PLA that was included with my i3 MK3S kit

I have the Filament defined as Prusa PLA

I am using the setting 0.15mm Quality M3 with the only modification being is to align seams

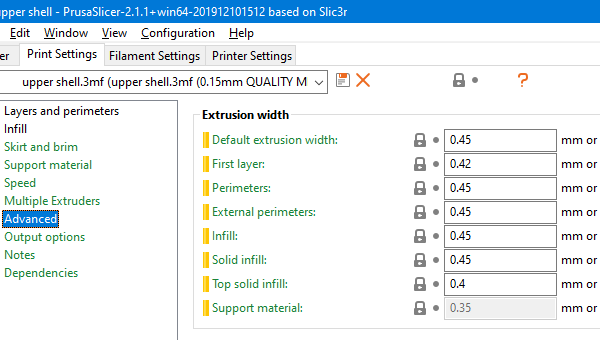

My model includes walls where part of the wall is dimensioned to be the 1.35mm wide, which is equal to 3 extrusions in PrusaSlicer, as defined on the Print Settings tab (0.45mm/extrusion).

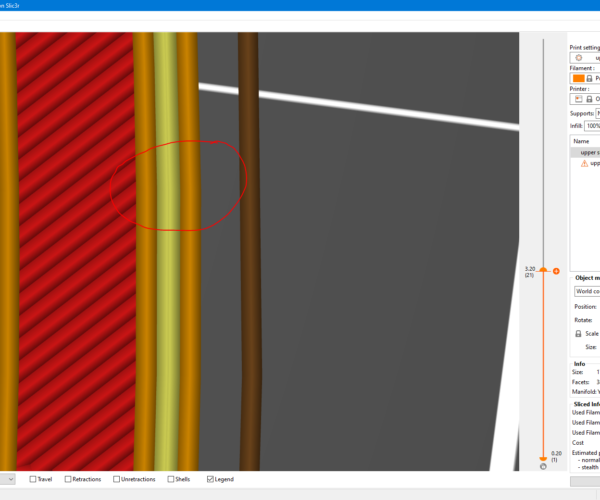

When sliced, I see 2 external perimeters and 1 perimeter in the center, but the perimeter in the center is a little wider than the external perimeters (measured on the screen). The effect on the printed model is that part of the outside wall is a little wider than the other parts of the wall. The effect looks like a shift, but is not an X or Y shift, as the object is oval and the effect appears on all the outside surfaces of the printed model.

When I change the wall thickness from 3 extrusions wide to to 3.5 extrusions wide, in PrusaSlicer I see 2 external perimeters, 2 perimeters, and a narrow gap fill, which is more material than expected (I expected to see 3.5 extrusions, not 4 and a bit extrusions).

Please help me understand if there is a bug in the Slicer? or a bug in the printer firmware, or if there is additional tuning I need to do within the Slicer settings so I can achieve the proper result.

I am including images of the 2 models after slicing, showing the affected area of the model.

I am including an image of the wall profile, from within PrusaSlicer.

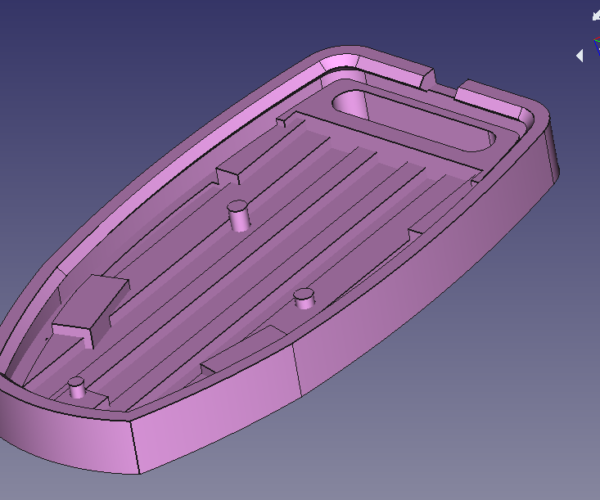

I am including an image of the model from within FreeCAD, showing it does not have bulging outside walls.

I am unable to include the STL file, but am including photographs of the printed object with the bulging wall.

Model with wall thickness=3.5 extrusions:

Model with wall thickness = 3 extrusions:

Model wall cross-section (affected area of wall is circled):

CAD model viewed in FreeCAD, showing wall is smooth:

Photographs of printed model, showing outside edges are wider, where circled in earlier images:

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model dimensions don't match slicer

The extrusions have to overlap slightly or they would not adhere to each other. Don't design your wall thickness based on n times the extrusion width.

To account for the overlap and determine what the slicer will end up doing for thickness, print a simple 20x20mm cube, with #desired perimeters, 0% infill, 0 top layers. Take it out and measure the wall thickness with calipers. Then use that number as your wall thickness when designing.

RE: Model dimensions don't match slicer

Thank you, vintagepc, but the underlying issue still exists.

If we ignore the point about how I derived the dimensions in question, the designed model and the printed model don't match; the slicer is altering my model and I would like to understand how to ensure the printed model matches how it was designed. If the dimensions in my model were unable to be altered, I would have discovered that 3D printing is of no value for making precise parts, and I don't accept that as a fact.

The bulging in the photographs don't appear in the images of the sliced model, so the printer or the gcode is creating the bulges.

Please help me to understand why the printed model doesn't match the sliced model or the CAD model.

Prusa i3 MK4S Kit in Lack Enclosure