Looking for a workflow to fix open edges in my model.

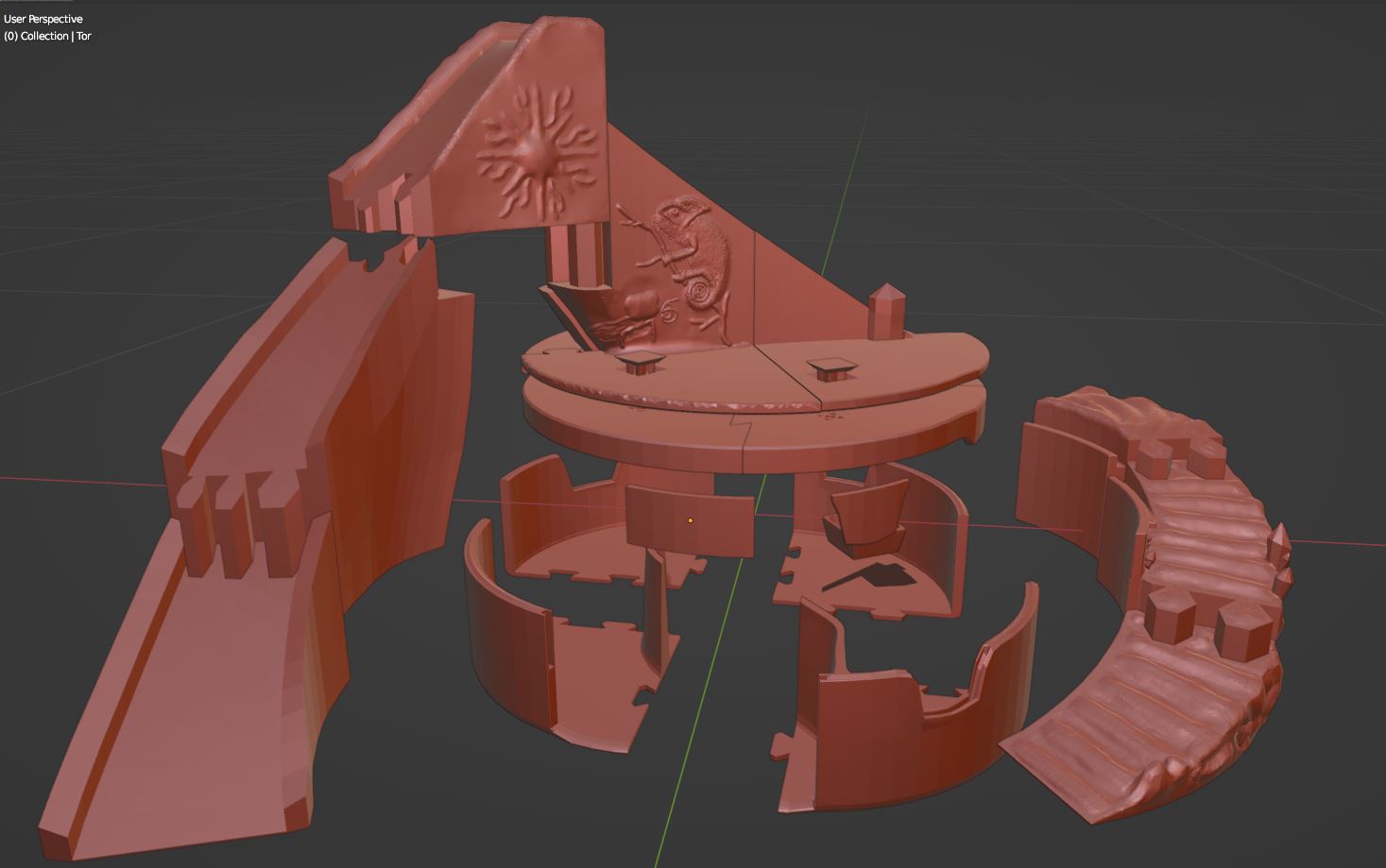

I imported my .stl file with 103 open edges (and 284 auto repaired errors) into prusa slicer. I assume the print would go without any complications still, but as this is only one part of a model of about 25 parts, and I will be likely to run into this issue many more times, I would like to get to know a solid workflow on fixing these issues, either by software or manually.

The most important thing is that I can see where the open edges are, is there a way to have those places highlighted in PrusaSlicer? With that information I could go back into blender and focus on exactly those spots. With the mere "103 open edges" I'm swimming in the dark due to the amount of vertecies in the mesh.

Secondly, the geometry of the model may not change, at least not on the surface level. The parts are designed to fit neatly into each other with about .02mm tolerance. From the online mesh fixing options that I have tried so far, they all changed the geometry of the model way too much, rendering it useless.

Third, the option should work on windows 8.1. I haven't been able to get Netfabb up and running due to this unfortunately.

Attached is a .m3f and a .blend file.

Best Answer by Neophyl:

Someone mention me 🙂 I wouldn't say I'm an expert on Blender. Its such a huge program and I really only touch the modelling side of things. I know very little about rigging or lighting for example, or UV unwraps as those stuff is for the rendering side of things. Also you watch some of the youtube vids of guys on there and the sheer speed they can manipulate things is mind blowing. I do know enough to get by though 😉

The very first thing to turn on in Blender if you haven't already is the 3D-Print tool. Its in Preferences > Add Ons. Its one of the Mesh tools. Its one of the built in tools that just needs turning on. That can run a report on what is 'wrong' with the model and it can highlight those areas. For example your blend object has - 73 Non Manifold edges (which are the thing that slicers really really don't handle well), 71 intersecting faces, 72313 Zero faces, 3 thin faces and 15 sharp edges. It also has 2189 Overhang faces (more than 45 degrees).

The 3D-Tool can also attempt to fix the non manifold edges too but the success rate varies.

The slicer can usually handle a certain amount of intersecting or zero faces as far as slicing goes. Where they do cause problems is when you are trying to paint an area, say for support enforcers or blockers. Often a zero or intersecting face can be painted as its 'behind' another. So for example you set support angle and it adds support where you don't want it so you paint a blocker in that area expecting the support to stop. Except it doesn't because there are these hidden faces that your blocker doesn't cover.

That's just one example of the sort of issues you can face.

This particular model the Make manifold button in the 3d-Print tool worked well and after I exported it (also using the 3d print tools single button export function) when I loaded it into your 3mf it came in with no reported issues and sliced fine. Although some of your settings could be better optimised on the slice side too 🙂

Like most programs you have to be very careful with booleans in Blender. Generally unions and joins don't work too well for 3d print. Its actually better to leave them un-joined and just select everything you want to export and then do the export to stl. That will result in a stl made up of several parts. The slicer will handle the overlapping geo just fine as long as the individual parts are manifold naturally.

There are also other advantages to doing that. You can split to parts in the slicer and selectively delete or move stuff if needed etc.

Give the tool a try and examine the areas it highlights. You want to be in edit mode after running the Check All option to see the areas

RE: Looking for a workflow to fix open edges in my model.

cannot upload the .zip folder for some reason (it is <10mb), maybe have to await moderation.

RE: Looking for a workflow to fix open edges in my model.

I'm saying this as someone whose time with Blender doesn't exceed 15 minutes, so take it for what it's worth. I'd be focusing my efforts on figuring out how to model in Blender to avoid those artifacts in the first place, rather than putting band aids on after the fact. I hope @neophyl sees this thread and chimes in because he actually knows what he's talking about when it comes to Blender and can advise on best practices.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Looking for a workflow to fix open edges in my model.

Someone mention me 🙂 I wouldn't say I'm an expert on Blender. Its such a huge program and I really only touch the modelling side of things. I know very little about rigging or lighting for example, or UV unwraps as those stuff is for the rendering side of things. Also you watch some of the youtube vids of guys on there and the sheer speed they can manipulate things is mind blowing. I do know enough to get by though 😉

The very first thing to turn on in Blender if you haven't already is the 3D-Print tool. Its in Preferences > Add Ons. Its one of the Mesh tools. Its one of the built in tools that just needs turning on. That can run a report on what is 'wrong' with the model and it can highlight those areas. For example your blend object has - 73 Non Manifold edges (which are the thing that slicers really really don't handle well), 71 intersecting faces, 72313 Zero faces, 3 thin faces and 15 sharp edges. It also has 2189 Overhang faces (more than 45 degrees).

The 3D-Tool can also attempt to fix the non manifold edges too but the success rate varies.

The slicer can usually handle a certain amount of intersecting or zero faces as far as slicing goes. Where they do cause problems is when you are trying to paint an area, say for support enforcers or blockers. Often a zero or intersecting face can be painted as its 'behind' another. So for example you set support angle and it adds support where you don't want it so you paint a blocker in that area expecting the support to stop. Except it doesn't because there are these hidden faces that your blocker doesn't cover.

That's just one example of the sort of issues you can face.

This particular model the Make manifold button in the 3d-Print tool worked well and after I exported it (also using the 3d print tools single button export function) when I loaded it into your 3mf it came in with no reported issues and sliced fine. Although some of your settings could be better optimised on the slice side too 🙂

Like most programs you have to be very careful with booleans in Blender. Generally unions and joins don't work too well for 3d print. Its actually better to leave them un-joined and just select everything you want to export and then do the export to stl. That will result in a stl made up of several parts. The slicer will handle the overlapping geo just fine as long as the individual parts are manifold naturally.

There are also other advantages to doing that. You can split to parts in the slicer and selectively delete or move stuff if needed etc.

Give the tool a try and examine the areas it highlights. You want to be in edit mode after running the Check All option to see the areas

RE:

Like most programs you have to be very careful with booleans

True that. OpenScad is another example prone to producing invalid STLs if you don't do the Booleans properly.

Its actually better to leave them un-joined and just select everything you want to export and then do the export to stl. That will result in a stl made up of several parts. The slicer will handle the overlapping geo just fine as long as the individual parts are manifold naturally.

PrusaSlicer is actually very good at it. But someone just made me aware of an issue with Cura for one of my popular models on Printables. It's created from OpenSCAD as several parts and Prusaslicer has zero issues with it. But Cura chokes on it. My knowledge of Cura is close to my knowledge of Blender--it's been many years since I've used it last—so this may very well be true to that user's settings. I'm just mentioning it because it highlights that the ability to deal with specific geometries may very well differ between slicers.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Looking for a workflow to fix open edges in my model.

glad you guys are concerned with my issues in depth here.

As a matter of principle I agree it is better to have a clean model to begin with instead of trying to 'put bandages on it' afterwards. The reasoning in requesting the later was basically to save time and because I didn't know about this 3d-printing addon (more in my reply to neophyl).

On this particular model I have to balance two things: On the one hand it is a sculpt, and thus consists of many thousands of vertecies. On the other hand, it is only one part and has to fit neatly into all the other parts to make it a whole.

My workflow made it seem very cumbersome to clean up the model in Blender itself. I started out modeling each individual part to fit with about 0.25 milimeters of tolerance. In sculpting you do a remesh where everything is converted into triangles and gains a much higher resolution (when using dynamic topology as I did). Unfortunately, this conversion process messes up the exact shape ever so slightly, which is unwanted wherever the surfaces have to remain exactly the same in order to fit. Another thing is that I want to avoid sculpting those spots accidentally, so I have to mask them. To be able to mask them however, I still had to add geometry a little bit, so the retopoloy process was a balancing act. This results in ugly topology at the border regions between the surfaces I want to sculpt and those that have to remain exactly the same.

Now this could be tidied up in Blender manually but it is extremely time consuming and so I was hoping to find a "pass-through" alternative.

RE: Looking for a workflow to fix open edges in my model.

The 3d-print tool seems amazing! With no introduction I was also able to fix the model in no time and have it in my slicer without errors or open edges.

This is exactly what I was looking for, I just didn't expect it would exist in Blender itself.

I don't yet fully understand the terminology, but I will look this up myself. Only one thing you might tell me, what are "zero faces"?

When turning those on, the AddOn covers almost the entire model and I simply don't know what discriminates those faces from those relatively few faces that were not highlighted. With the other Spots I might not understand exactly what the terms mean yet but I can see how they highlight "messed up" geometry, which is very useful. The overhang faces in this case cover only the bottom faces so this didn't seem like an issure to me. I use a slight bevel at the bottom and the 3D printer had no issue with this fortunately.

You mentioned some of the slicer settings could still be optimized, would you mind elaborating on this? I only started 3D-printing about a year ago and am very keen on learning how to optimize my settings.

One thing I'm desperately looking for for example is some G-Code to turn off my printer automatically once it has finished but this would go off topic and afaik it's not possible for an Ender-3 V2.

I attached two pictures of the complete model so you get an impression of what this individual part belonged to, it is fully modeled but still in the sculpting stage. If you have a suggestion to improve the workflow mentioned above this would also be very helpful.

Cheers

RE: Looking for a workflow to fix open edges in my model.

Yeah the 3d print tool is great isn't it 🙂 I thought it was some game terrain when I saw the original part, but now maybe a marble run ?

This article was useful to me when I first started using Blender - https://www.blenderbasecamp.com/home/what-are-zero-faces-in-blender-and-how-do-they-affect-3d-printable-models/

Generally though most time zero faces don't cause an issue. The main one is the non manifold and sometimes intersecting geo. As you can adjust the settings in the 3dprint tool you can dial the degenerate setting way the heck down or even off by setting 0.0. Also yeah the overhang tool isn't that useful unless you are modelling with the final print orientation in mind (which you should be anyway). 45 degrees is very conservative though as you should be able to print overhangs greater than that.

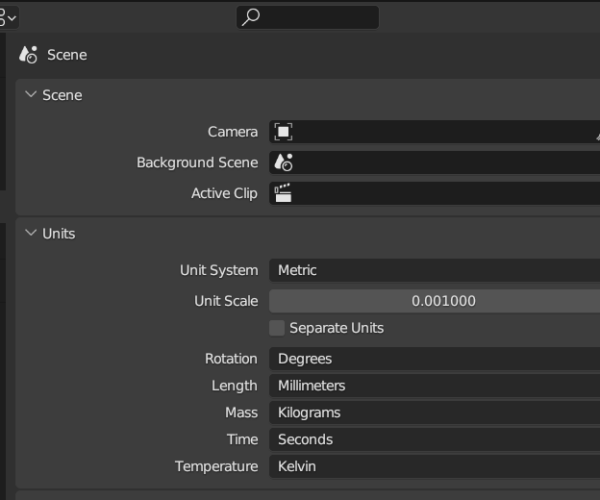

One thing about your Blender environment, when I loaded your blend in I noticed you have your Units set to meters. Not the most convenient for printing where the slicer expects mm. Lots of mental math for you to do in Blender. Set them like -

The Unit Scale and Length. That should allow you to see all the values in MM.

On your print settings, personally I'd turn off Thick Bridges. While not applicable for this model Thick bridges is a hold over from when that was the only option and so its still enabled by default so as not to mess with anyone's old existing profiles. I have yet to find a case where having it on gave a better result.

Cubic infill is great and its my default too. Its as strong as gyroid on a per weight ratio and has the advantage of producing smaller gcode as its made up of straight lines rather than curves. I think it supports large flat surfaces better too. On this model though you might want to check out support cubic.

Another infill one, Under Infill>Advanced you have Solid Infill threshold set to 70. This is another 'old' default. It means its filling in several of your smaller crystal features with solid infill which don't need it and could result in over extrusion. Generally its best to set it to 0 (Off) and only enable it if you specifically need it.

Another one to change on general principles is the Print Settings>Advanced>Slice Gap Closing Radius. With the default setting of 0.049 it will cause issues when printing things like flexi models or ones with built in hinges. Also tolerance testing prints. It just removes small gaps. Adding an extra 0 in there to make it 0.005 is my normal setting.

This model isn't using support but Grid is the worst type. Snug is a great improvement over Grid and still better than the new Organic supports in the 2.6alphas as far as I'm concerned in most cases. Organic is good for figures and such. Would be great if you could define a mix of support types 🙂 Which has been requested on Github.

RE: Looking for a workflow to fix open edges in my model.

great advice! I'll keep you updated on how it afffects my prints.