Issue with slicing very Thin edges.

Hi,

For the first time I am facing a strange issue.

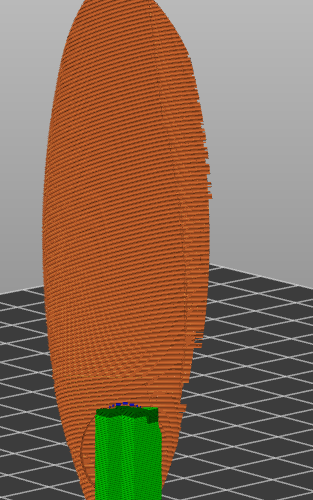

When I slice in the latest Prusa Slicer I am having issues with the edges with very thin part.

Initially I thought it was just the issue with the screen display but when printed it is coming in the print too!

Attaching the image and sliced image screenshots with this email.

Request help!

Best Answer by Neophyl:

I can see now why arachne is having trouble with that trailing edge. And why classic is also having trouble. It comes down to a mathematically thin line and the distance varies on the curve, especially seeing as the precision the model has been output at, is leaving a non uniform surface smoothness. You can easily see the triangles used to approximate the surface. The thin edge is not good design for 3d printing.

That trailing edge has to have 'some' thickness. It would give you a more controllable slice if it was modified to have even a minimal thickness like 0.2-0.3mm. If you really need it that thin then you post process it afterwards.

Aside from the design issues the reason you are having trouble with the classic perimeter generator too is you have Detect thin walls turned ON. That function is known to have problems and is a crutch for bad design. It should always be turned off unless absolutely needed as its outcome is unpredictable.

If something doesn't print because its too thin then you change the design until it does or you change the nozzle and extrusion width until the hardware is capable of printing the small geometry you want.

Its printable but it wont be very strong. The gapfill being used will also be increasing print time and will also probably produce surface artefacts. By switching back to Arachne and playing with the various settings you can also get a mostly ok slice too. As I think you are going to have to post process these regardless then printing both types and seeing which works best would probably be a good idea.

I think if you modify the design slightly to give thicker edges to work with then you could improve things a lot.

I've attached examples of both for you to examine.

RE: Issue with slicing very Thin edges.

Try changing XY Compensation to say 0.1mm or 0.2mm it will thicken the part artificially, once you get the part showing properly, reduce the value until just before the edges go rough again.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Issue with slicing very Thin edges.

Thank you for the reply.

Can you please guide me on how to do it?

Do you mean make the change in Prusa Slicer or the Firmware?

RE: Issue with slicing very Thin edges.

Hi Sid, not at my pc at moment. iirc. In expert mode. In prusa slicer. Choose print settings, advanced... And xy compensation should be half way down the screen

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Issue with slicing very Thin edges.

Arachne seems to have some issues with some thin edges. There have been several github issues raised around it.

For an initial go, try switching back to Classic printing mode in PS. Print Settings>Layers and Perimeters>Advanced> Perimeter Generator. Its a yellow setting so you need to be in at least advanced to see it.

Good memory Joan, the XY compensation is exactly where you mentioned. That one is a red setting so must be in Expert mode to see it.

If you want to save your project file and attach it we can take a look at all your settings. File>Save Project As and then take the resulting .3mf file, zip it up and attach it. Must be zipped for the forum to accept it. Project files are a snap shot and contain everything that you are slicing with so allows others to more easily figure out what's happening.

RE: Issue with slicing very Thin edges.

Joan,

I did change the XY Compensation value and it did help on getting those thin edges but now it refuses to generate support on the "painted" area....

When I change the XY Compensation back to Zero it immediately start showing those painted supports after slicing but not when the value in XY Compensation is anything but Zero.

Any idea why?

RE: Issue with slicing very Thin edges.

the XY Compensation value has increased the weight of the the print which is an issue for me.

the same file is sliced and printed perfectly on a Ultimaker using their slicing software.

what can be wrong with Prusa Slicer?

RE: Issue with slicing very Thin edges.

It's difficult to make accurate answers in the absence of the actual files,

could you please save the project as a .3mf file in prusa slicer, and then compress the file into a zip file, and attach the zip file to the next post?

Some designs, particularly aircraft designs, are created to take advantage of features within particular slicers

it may be that prusa slicer is not the best option for slicing this model.

is the orientation that you have shown, the recommended orientation?

having so many layer lines in the demonstrated orientation is likely to result in a very weak model.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Issue with slicing very Thin edges.

attaching 3mf file to this post.

RE: Issue with slicing very Thin edges.

You need to zip the 3mf project file for the forum to accept the file.

RE: Issue with slicing very Thin edges.

Done!

Attached Zipped file with 3mf.

RE: Issue with slicing very Thin edges.

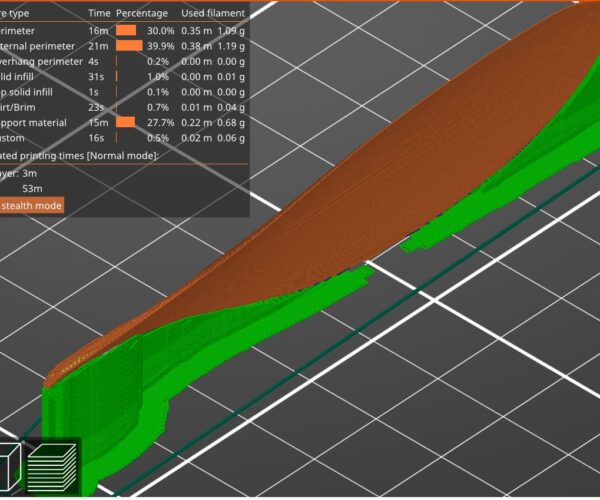

I can see now why arachne is having trouble with that trailing edge. And why classic is also having trouble. It comes down to a mathematically thin line and the distance varies on the curve, especially seeing as the precision the model has been output at, is leaving a non uniform surface smoothness. You can easily see the triangles used to approximate the surface. The thin edge is not good design for 3d printing.

That trailing edge has to have 'some' thickness. It would give you a more controllable slice if it was modified to have even a minimal thickness like 0.2-0.3mm. If you really need it that thin then you post process it afterwards.

Aside from the design issues the reason you are having trouble with the classic perimeter generator too is you have Detect thin walls turned ON. That function is known to have problems and is a crutch for bad design. It should always be turned off unless absolutely needed as its outcome is unpredictable.

If something doesn't print because its too thin then you change the design until it does or you change the nozzle and extrusion width until the hardware is capable of printing the small geometry you want.

Its printable but it wont be very strong. The gapfill being used will also be increasing print time and will also probably produce surface artefacts. By switching back to Arachne and playing with the various settings you can also get a mostly ok slice too. As I think you are going to have to post process these regardless then printing both types and seeing which works best would probably be a good idea.

I think if you modify the design slightly to give thicker edges to work with then you could improve things a lot.

I've attached examples of both for you to examine.

RE: Issue with slicing very Thin edges.

Hi,

Thank you for the reply.

The same file gets sliced perfectly on a Ultimaker machine using Cura for Slicing.

Absolutely perfect slicing and printing happened... with the above combination.

Will check your file too! Also the "Detect Thin Wall" option was "Default Ticked" and not allowing me to disable it at any cost!

RE: Issue with slicing very Thin edges.

Detect thin walls is not used for arachne slicing as it no longer serves any purpose with that slicing engine. In Classic though it is editable. Did you by any chance try and disable it when you had arachne selected ?

And yes it is on by default, which is not ideal as it causes just as many issues as it 'fixes'. Many many threads here and issues on github around it. Unfortunately Prusa don't like altering existing profiles too much. Just turn it off and leave it off is the best advice.

RE: Issue with slicing very Thin edges.

Hi,

Thank you for the reply.

The same file gets sliced perfectly on a Ultimaker machine using Cura for Slicing.

Absolutely perfect slicing and printing happened... with the above combination.

Will check your file too! Also the "Detect Thin Wall" option was "Default Ticked" and not allowing me to disable it at any cost!

Detect thin walls is not used for arachne slicing as it no longer serves any purpose with that slicing engine. In Classic though it is editable. Did you by any chance try and disable it when you had arachne selected ?

And yes it is on by default, which is not ideal as it causes just as many issues as it 'fixes'. Many many threads here and issues on github around it. Unfortunately Prusa don't like altering existing profiles too much. Just turn it off and leave it off is the best advice.

noted! will do as advised!!! 🙂

RE: Issue with slicing very Thin edges.

Hi Sid,

I also had a look at the file...

I saved the STL and loaded it into Simplify3D and got

which looks like it sliced properly, but if you look carefully on the left side, the trailing edge has been cropped...

I took a different approach to yourself and Neophyl

You say Cura sliced the file without error... is it possible that it sliced the file like S3d, and simply trimmed off the bits it had difficulty with?

I thought that printing the blade vertically as you offered it, would lead to lots of inter layer joint lines across the blade, which I believe would make it relatively fragile

so I re orientated the stl as you see

I have done an example with 0.25 nozzle

propBlade JT

If you were to add XY compensation you could print it with a 0.4mm nozzle, yes, it would increase the weight, but, you could sand the blades after printing, which would have the benefit of reducing the weight and reducing air friction on the prop blades the inter layer bonds going along the blades would increase the strength of the blades and the supports would be easy to remove with little impact on surface finish.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK