Issue with magnet holes when spliting to parts

Hi,

I have an interesting issue with pruusa slicer. I am doing leg for a badge stand which suppose to have 2 covered holes. One on the bottom of the leg to hold leg on base stand and one on the top of the leg to hold the badge. I am using Fusion 360 and the holes are standard cut with 0,4mm offset. I wanted to stop printing in certain point to glue magnet inside the hole and let the printer cover the magnet with additional layers of material.

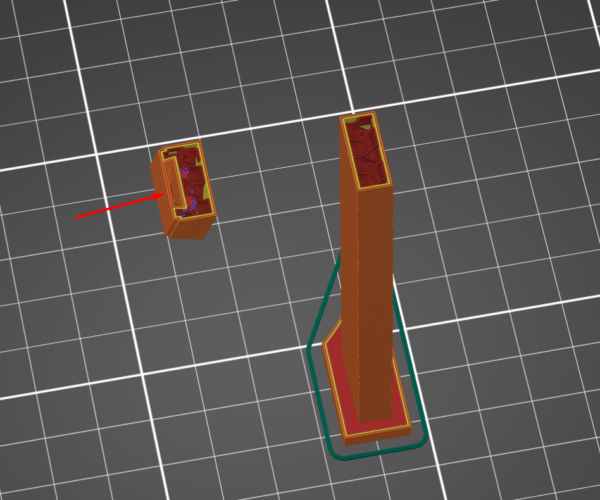

The thing is that I need to slice the model to avoid massive supports. I split the model to parts inside the fusion and saved as STL. If I slice the model without splitting to parts, all works okay however when I use split -> to objects (or to parts) the slicer evaluates the holes as objects itself. So the holes disappear from the object but become a new solid objects. I tried Cura and all works ok however I am not very familiar with it so It was just to compare If I do something wrong or Cura.

I can provide STL itself to evaluate.

RE: Issue with magnet holes when spliting to parts

Not sure I understand:

The thing is that I need to slice the model to avoid massive supports. I split the model to parts inside the fusion and saved as STL. If I slice the model without splitting to parts, all works okay however when I use split -> to objects (or to parts) the slicer evaluates the holes as objects itself.

Looks like you split the model in Fusion. What happens when you print the parts? I don't see why the slicer would change anything.

Or did you split the model in PrusaSlicer, as the next sentence indicates? Or both?

Your best bet for optimizing supports is probably generating separate components in Fusion. Again, looks like you've done that but I don't understand what problem that caused.

To stop printing at a certain point, you can slice the model, and in the print preview use the vertical slider on the right to go to the layer where you want to stop. Then right click on the plus sign and select Add pause print (M601).

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Issue with magnet holes when spliting to parts

Please provide the stl files in a zip but also your saved Prusa project file so we can look.

are you by any chance doing a Boolean operation for your magnet holes ? A Boolean remove in your cad will likely be using one mesh to remove areas from another. When that’s evaluated and output properly you get a hole. If output as parts then they are all just separate meshes so it’s no longer a hole but the mesh shape used to cut the hole.

RE: Issue with magnet holes when spliting to parts

Another thought is that when you add the cutouts for the voids you'll be placing the magnets in, make sure the voids are actually attached to the primary part in Fusion - and not left dangling as separate shells. I'm not a Fusion user, but this has happened with other tools I have used. In some cases you need to provide a "vent" so the geometry can be identified as internal and external faces. In other cases its as simple as merging the void with the part. Seems the more complex the tool the harder it is to control inside vs outside.

RE: Issue with magnet holes when spliting to parts

@fuchsr

In fusion I modeled 2 parts - stand and leg as separate components so as 2 separate models. The one on the screens is the leg. I split the leg to better print however I tried STL without that split so it's in one piece with same result. No splitting in prusa slicer

@Neophyl

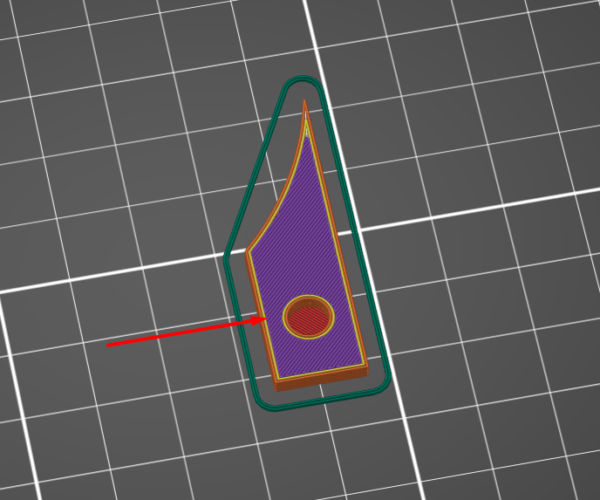

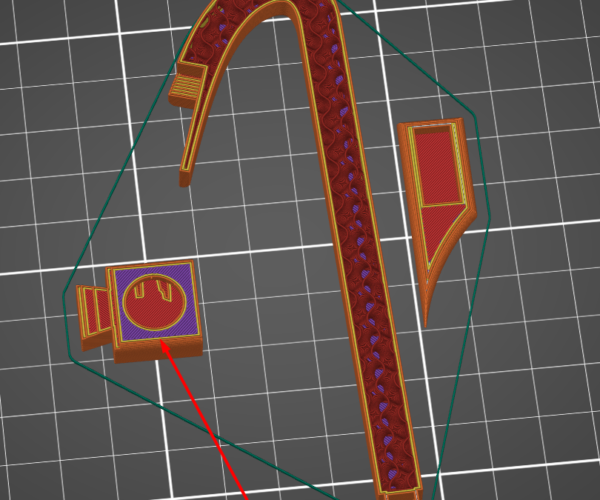

Magnet holes are simple offseted cut as on the picture below. I am not aware of any boolean operation

I am posting zip of STL with + without split + 3fm file with split and sliced stand. There are 2 things which are pretty weird:

1) Magnets holes are separated box

2) If the model is not split to parts. you can see that slicer didn't cover top magnet hole with another layer. It's just a visible hole

Btw. Is it possible to upload a zip file here? I tried to upload via insert media -> upload file but it says zip is not supported. Anyway, here is link to my gdrive with zip file. https://drive.google.com/drive/folders/13NtDusdG6X3b0KuP8sYJpeqs0_DbYduM?usp=sharing

Thanks in advance

M.

RE: Issue with magnet holes when spliting to parts

@majusenko

You must place non-image files in ZIP archives, then they work.

sp: your link is broken - the file there is not downloadable.

RE: Issue with magnet holes when spliting to parts

I tried zip file with 2xSTL, 1x3MF, click Add media -> Upload and choose file but "Sorry, this file type is not permitted for security reasons". Anyway. Try the link without the sharing. I tried it from different computer and it worked. Try it without that sharing string https://drive.google.com/drive/folders/13NtDusdG6X3b0KuP8sYJpeqs0_DbYduM

Anyway, I made some tries and realized that if I left magnet holes opened from one side all works even with split function in prusa slicer.

RE: Issue with magnet holes when spliting to parts

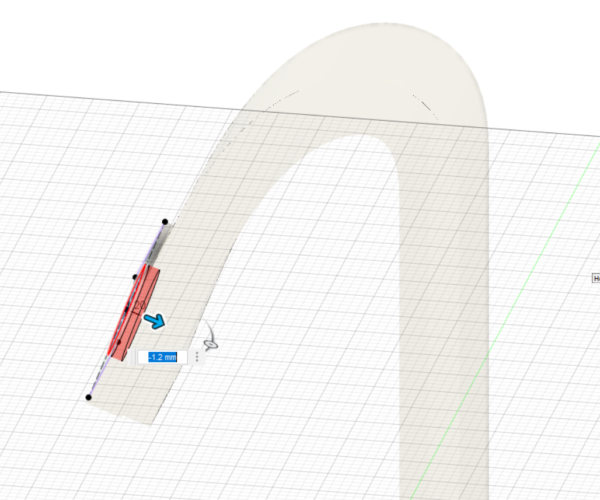

So I managed to workaround the issue. Didn't find the reason why in prusa it's making this weird thingie. However I decided to update my CAD design. So I prepared som dovetails and by it I split model to several parts in CAD. So I didn't have to make "Split to objects" in prusa. I simply made several bodies, saved them as STL separately and then imported in one file.

In design itself I changed magnets inside a stands to magnets which are not enclosed (not because the issue but cause I changed the way how to assemble it)

For the top magnet - it stayed inside the printing object however it's working correctly cause I enlarged the area of the object. And till I use split to objects I don't have problem with inside cuts...

So this is it. I still think slicer is not working correctly in this scenario (or maybe I have to draw it differently) but I had to change my design several times to allow nice printing and luckily I was able to make all I needed without tradeoffs.

RE: Issue with magnet holes when spliting to parts

If I put your full model in the slicer, then i see no hole on top, after slicing 0.2 mm there is a hole, your model is not good, possible to thin.

If I slice with detect thin walls I get the upper whole closed, but hole still visible.

Your model is not solid I think, and walls are to thin, check how thick a wall needs to be wen you print, if you go lower you get problems.

A model needs to be one part, and solid.

RE: Issue with magnet holes when spliting to parts

@majusenko

ZIP files are acceptable. A project file saved from Pslicer in .3mf format, placed into a zip archive, is easily postable here. A simple drag-and-drop operation. The project file includes settings, profiles, and models: everything needed to recreate a print.