Internal overhang and bridging speeds

Hello,

I would like to ask you a question about internal overhangs and bridging in the slicer.

There is a feature to reduce the print speed on the overhangs that works pretty good, but this feature only work on the external overhangs.

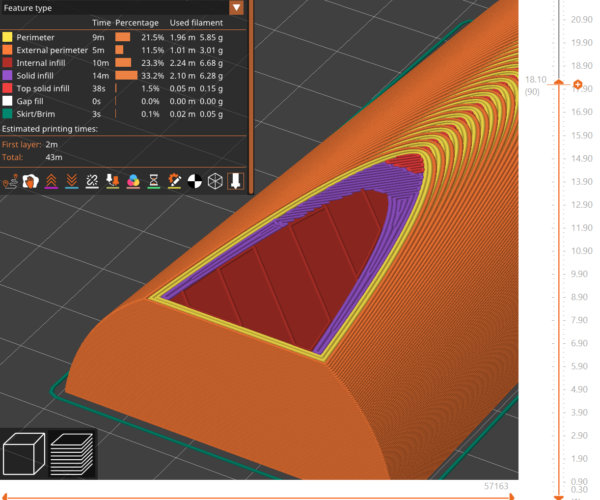

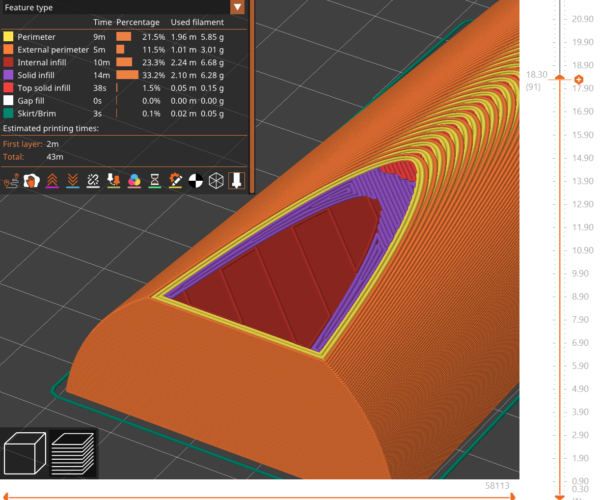

My issue is that when printing at high speeds that printers support without issue these days (200mm/s), I have to greatly reduce the speed of the solid infill (60mm/s) in order to achieve a good quality of the print on the surfaces that are shown as an example in the added picture. I can not upload the stl here.

The issue is that the slicer is not taking in the account the material printed in the air inside the model - meaning that previous layer is flawed and the problem snowballs.

Would it be possible to enable the speed of the print decrease for every overhang move (external and internal) in order to increase the overall speed and quality?

I understand that the issue might be hard to explain, so please if this doesn't make sense, I will try to explain myself better.

Thank you,

Milan

RE: Internal overhang and bridging speeds

You can't add more infill to support those overhangs?

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Internal overhang and bridging speeds

Hi,

definitely could do that, but it would not be a good solution, I m normally printing 350x350 moulds with more than 1kg material per mould, if I was to increase the infill it scales badly.

Please do understand that I have done a workaround with lowering the solid infill speed, but in the age of cnc this feels like a crude solution to a problem that can be solved by reducing the speed at overhangs rather than on the whole solid infill feature (this is actually adding hours to the overall print time).

Also as you can see from the pictures - slicer is providing a tool paths that end in the air - meaning that the bridge ends in the air and goes back again - this can not print well compared to the bridging that ends constrained on the infill or perimeter.

Thank you for your input.

Milan