Idea to Improve Layer Adhesion with "interlocking layers"

So the purpose of this idea what i call "interlocking layers" is a to improve layer adhesion, and side load handling of printed parts.

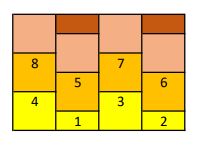

The idea is to print the lines half a layer shifted up from the one next to it. If we print with a "standard" .2 mm layer height and for the example we have 4 walls, on the first layer we print the 2nd and 4th wall at a layer height of .1mm, the outside wall and 3rd wall at the normal height of .2mm. After that every layer except the top most is at the normal .2mm thickness. The reason for this is to shift the layer lines from each other. With this its not only the top/bottom of the layers, but the side of the lines aswell which are in contact with the previously printed one. That also improves side load handling of the prints, because its not a slingle plane between the layers, but many crossing lines.

I believe that this would not increase print times by mutch, since we are only mooving half of the lines up which normally has to be printed too.

I made a really basic illustration of the idea, the numbers are the print order in this example.

RE: Idea to Improve Layer Adhesion with "interlocking layers"

Not a new idea. Been proposed many times before. There are even opened issues on github for both Prusa Slicer and Super Slicer.