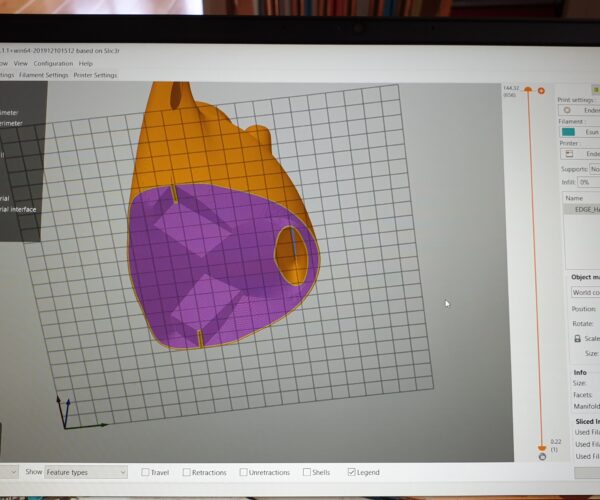

how can I remove top and lower infill density ??

When slicing thin wall stl files from 3dlabprint I get top and bottom infill density automaticly added.

How can I remove this setting in the configuration ?? I can't find it.

Found it in creality slicer (picturee added) but I prefer to use prusaslicer for better print results.

RE: how can I remove top and lower infill density ??

are you trying to print without top and bottom layers? to produce a shell?

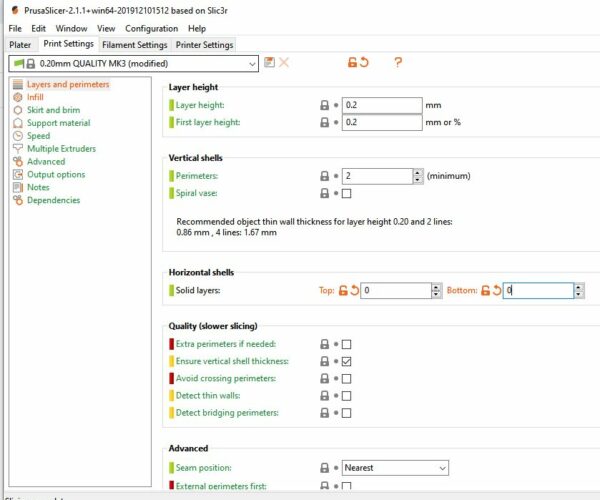

Try setting Horizontal shells to 0 for top and bottom!

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: how can I remove top and lower infill density ??

Thanks 🙂 this is the solution

Now I am looking for wall thickness adjustment (thin wall printing) in prusaslicer.

Found it in creality slicer but perhaps by selecting thin wall printing in prusa this will do the trick

RE: how can I remove top and lower infill density ??

HI Guusk,

How thin do you want the walls to be?

In Prusa Slicer, your model is normally described by

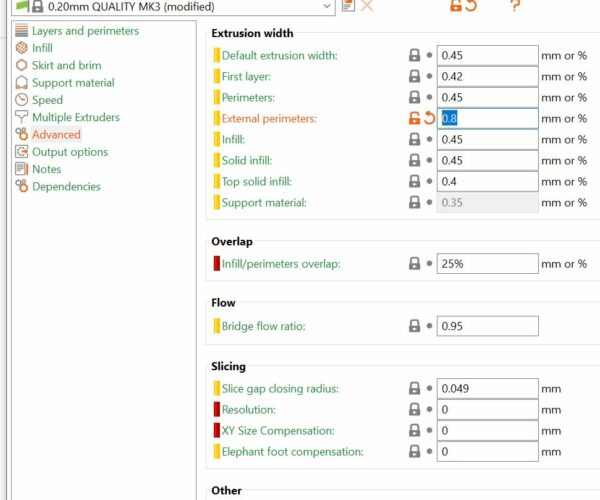

Nozzle Diameter (default 0.4mm) (You rarely print with extrusions the same width as your nozzle, so 'Extrusion width' comes into effect.)

Layer Height (Layer height is also capable of being flexible! reducing layerheight on curves can give a better finish)

Number of Perimeters, (this can be complicated by the 'Ensure wall thickness' option)

Number of Top Layers

Number of bottom layers

Infill percentage

This Lamp globe, (Sorry it's 90 degrees turned!) is printed in Vase Mode, with

Zero top layers,

Zero Bottom Layers,

One Perimeter and

5mm brim.

BUT... I expected it to be quite weak especially on the curved surfaces as the extrusion width was set to the default 0.4 mm

SO I increased the 'Extrusion width' to 0.8mm which made the shell stronger, (this is an 'Advanced Mode' Option (select advanced mode in Prusa Slicer))

Note! In Vase mode you can ONLY PRINT ONE PERIMETER!

I find that two perimeters at default extrusion widty of 0.45mm (0.9mm wall thickness) less robust, than one perimeter at 0.8mm extrusion width) you are probably looking for robustness and strength. within a light solution

Also raising the print temperature tends to improve the inter layer bond strength, which is important on structural thin wall prints.

Vase Mode will not work properly with your cowling, because there are two separate areas to the print!

the 'Outer Shell', and the 'Air Duct'

Vase Mode attempts to complete the entire print in one spiral, Jumping up the layer height at the beginning of each layer rather than stopping and starting... this typically prevents the stopstart seam forming, giving a more pleasing result.

Where there are two separate areas to the print, Vase Mode, MUST Stop and start, as the extruder passes from one area to the other...

so you may want to set the 'Seam Position' to ' Random'!

Don't forget, when you reduce the model to just perimeters, you will have very little area for adhesion on the build plate, so adding a Brim, will improve adhesion, additionally making sure the build plate is impeccably clean, will improve adhesion for PLA

I hope this helps.

P.S. the creality slicer does the same things in different ways, so you are unlikely to find the same names used for features between the two slicers

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK