Hot to get constant print / extrude speeds

Hi, I'm new to Prusa. Got experience with a Ultimaker S5 + Cura and now bought a Mk3s for printing flex. I'm struggling to get a constant extrusion and nozzle pressure rate, leading to clogging and filament tangles. There seem to be a bunch of conflicting or automatic settings that are new to me. Cura would print everything at the same speed if I tell it to do so, PrusaSlicer seems to have its own mind.

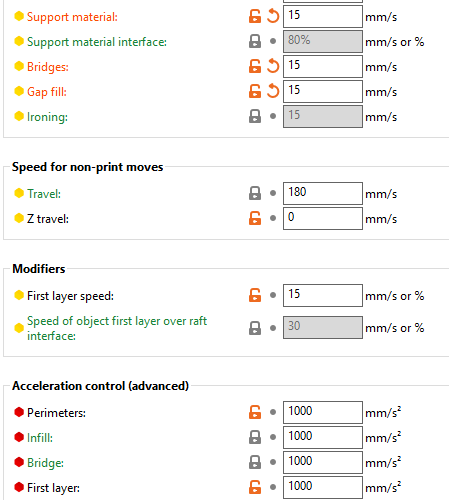

I have set all "Speed for print Moves" parameter to 15mm/s. Yet the printer prints infills still much much faster than e.g. walls. The extruder gears start spinning and that's it, jammed.

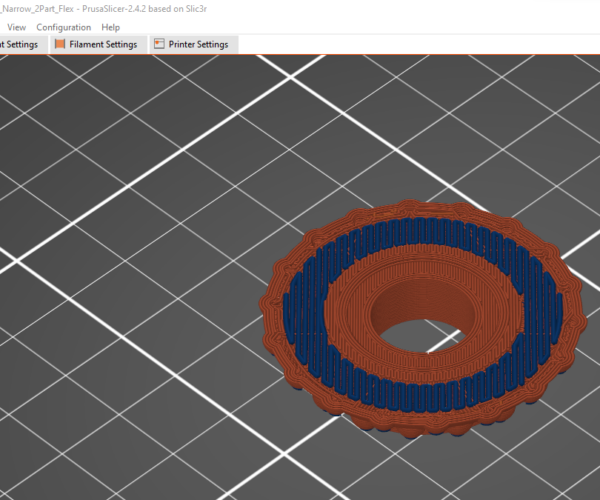

I tried then lowering max volumetric speed. It exists twice, under Print Settings->Speed->Autospeed and Fillament->Advanced. Both have an effect on the print time so they both seem to be used. I don't know when autospeed is used and how to disable it. This seemed to do the trick for constant extruder gear speed, however the nozzle moves much slower for infill than it does for the walls (lower speed at same extrusion = thicker lines , see other screenshot). This leads to too much back pressure and the filament jams again.

I can extrude manually totally fine for hours without any jamming, but I can't get the tool to do a nice continuous print. All I want is to have everything printed at a same rate and same slow speed in combination with high speed travelling, ideally I even don't want the extruder to stop spinning during travel, it can keep oozing a bit, that's fine with my print.

Here's a screenshot of the settings. I tried to upload the project file but the forum won't let me add 3mf. I uploaded it in my onedrive, hope that works:

Handle_Pimples_Narrow_2Part_Flex_4Forum.3mf

If you zip the file the forum will accept it.

Cheerio,

RE: Hot to get constant print / extrude speeds

Speed may be different but the volumetric flow is the same for everything. That means filament is being extruded at the same rate. On your Print settings profile under Speed you have it set to 2mm/s/3 max speed, this is what its controlling the speed with (your filament profile has 7.5 set for volumetric but the 2 is over riding that). To keep to the same volumetric the speed has to vary for different features.

If you want a constant print speed (which is NOT a constant volumetric flow) then you have to make sure that there are no volumetric limits in play. So on your print profile set that one under speed to 0 to disable it and you also need to set the one under your Filament profile to 0 too otherwise that will limit some parts.

Also I loaded your 3mf in and the filament profile is for a modified Generic PLA, not flex. Did you modify one as the base rather than using a Flex profile to start with ?

Attached a modified project with a 20mm constant print speed, all except the first layer which uses the first layer speed.

RE: Hot to get constant print / extrude speeds

Ran out of edit time 🙁

For a more general explanation of how PS works speed wise. It will generally use the speeds you have defined in the speeds section. However as you have discovered these can be modified by a few other settings. Volumetric limits as you have discovered. Think of the volumetric as the maximum amount of plastic your 'system' can handle. System in this case being both the physical elements like the extruder but also the material being printed. Its why you can set it in multiple places. Some filaments need a lower value. The slicer will use the lowest of any set. So you would normally set the maximum your printer can do with the easiest material (like PLA) in the Print profiles and then use the filament profile to set a lower more restrictive one if needed for a material if needed like Flex. Volumetric is sort of like a top speed limiter.

The other setting that can alter speeds and often catches people out are the cooling options under filament. Theres a 'Slow down if layer print time is below' option that can proportionally slow things down too. That's not a factor on your project as you have all that turned off in your filament settings but its something to be aware of in general.

RE: Hot to get constant print / extrude speeds

Neophyl clearly described the impact of MVS on speed. You should definitely start with the Generic Flex filament profile unless there is one for your specific brand. I've used a few brands of TPU, and Generic Flex gave me good results for all of them (with some minor temperature adjustments). There may be ways to further optimize it but it's better than starting with a PLA profile

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Hot to get constant print / extrude speeds

Thanks for all your replies and the detailed explanations 🙂 I think I found the issue in the way Prusa decouples different settings/profiles which should not be independent from each other. In my case setting the nozzle size to 0.8 did not change the line widths accordingly. The resulting slicing behavior is still unexplainable to me. I guess its has hard limits and can't got below a certain percentage of the nozzle diameter with the extrusion width and then sliced nonsense without giving a warning.

I understand the difference between flowrate and print speed. I wanted both to be constant. I had all, line width, print speed and flow rate constant. However it would slice features in different line widths --> having the flowrate fixed lead to change in print speed, having print speed fixed that leads to change in flow rate.

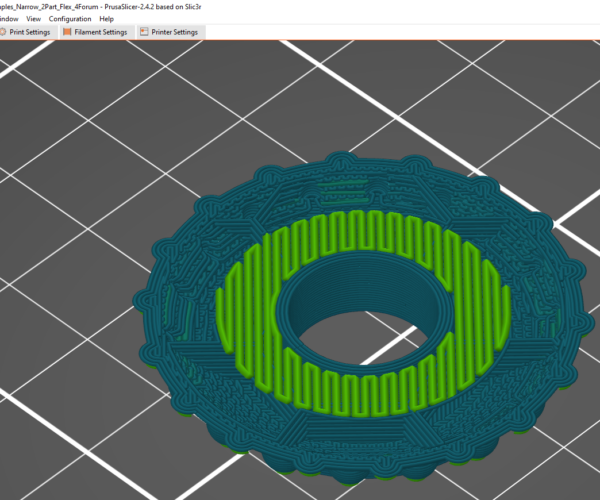

This is the line width view with line widths set to 0.42mm, all printing speeds 20mm/s. Flow rate limited to 2mm/s. The line widths vary like crazy and are everything but 0.42mm, leading to back pressure and the nozzle clogging for the thick lines.

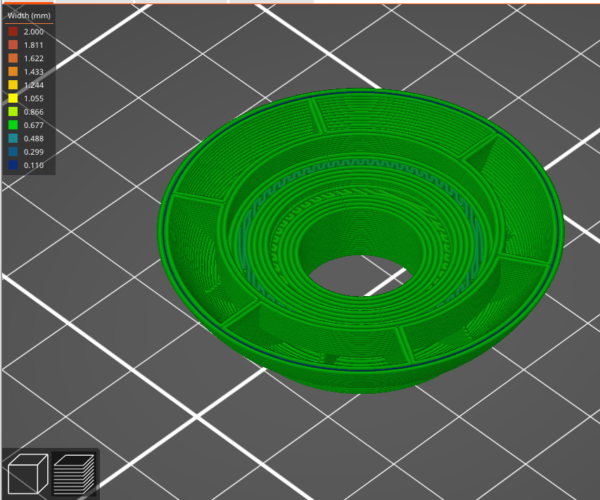

I started from scratch, set all parameters to their defaults and now it works. E.g. extrusion widths shows default=0 which means it is calculated based on nozzle diameter. However all the profiles set them to a hard value instead of a percentage and when I changed the nozzle stuff got messed up ( those hard values are even hidden in simple mode while nozzle diameter can be set --> simple mode is not usable for e.g. a nozzle change).

The way profiles are setup gives me a headache anyways. Filament, printing and printer settings are all their own separate profile though they cannot be threated independently for different materials, leading to a clutter of combinations that make no sense. In cura everything except the physical machine dimensions/limits, is attached to one material profile. So if I load my profile for e.g. Nylon it will lower print speed, fan & retraction, increase travel speed, increase temperature, increase line width etc. I think in future I will just always go through the process of setting every single parameter manually and saving that material setting as a project instead of using profiles.

RE: Hot to get constant print / extrude speeds

But even now there are still some super thin lines creeping in. How can I tell the slicer to just skip those. The model is a hollow sphere, so there will always be some angle where the wall thickness is no multiple of the line widths ( as the printer moves in Z while the sphere wall rotates around an axis). The slicer then tries to squeeze in tiny line widths. Is there some tolerance setting to leave those spaces just empty or maybe allow the slicer to print thinner/thicker if the line width doesn't match the wall thickness of the model perfectly. Here in this picture I worked with a 0.6mm nozzle, 0.7mm extrusion width and it tries to squeeze in that dark blue 0.1mm line, leading to a factor 6 change in either flow rate or speed, both very bad for flex:

RE: Hot to get constant print / extrude speeds

I’m not at my pc at the moment but it’s probably gapfill. Gapfill throws off lots of the calculations. Same as supports can. You can turn gapfill off. It will leave spaces though.

You might want to wait until 2.5 is ready as that has ported the Cura Aracnae engine over and it can adjust widths so you don’t need gapfill.

btw zero doesn’t mean nozzle width on extrusion widths. Read the tool tips VERY carefully.

RE: Hot to get constant print / extrude speeds

You can also use height range modifiers to adjust extrusion width along the way as needed to try to address the changes in curvature that leads to the creation of gap infill.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/