Gaps and blobs

I have a few oddities occurring. Firstly my settings are .6 nozzle, .65 extrusion width and 1.08 extrusion multiplier

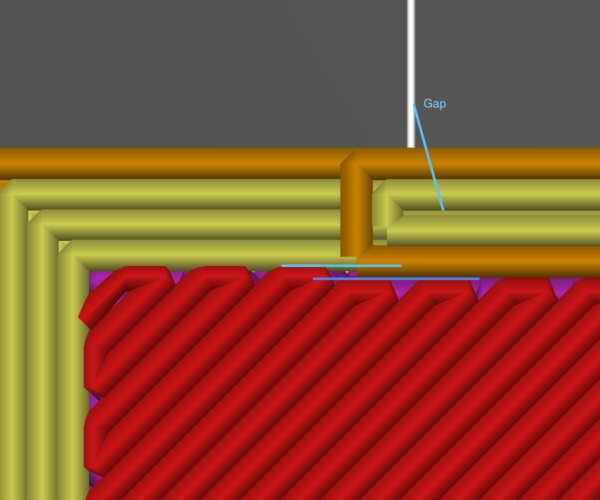

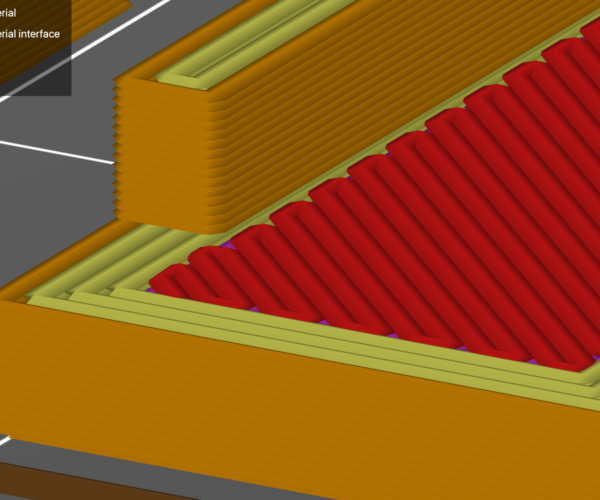

- Image 1 and 2: is an upstanding wall on a slab. The upstand is 2.6mm thick yet prints wider than this and leaves a slither of a gap. In the image you can see the perimeter total is wider than the slab below.

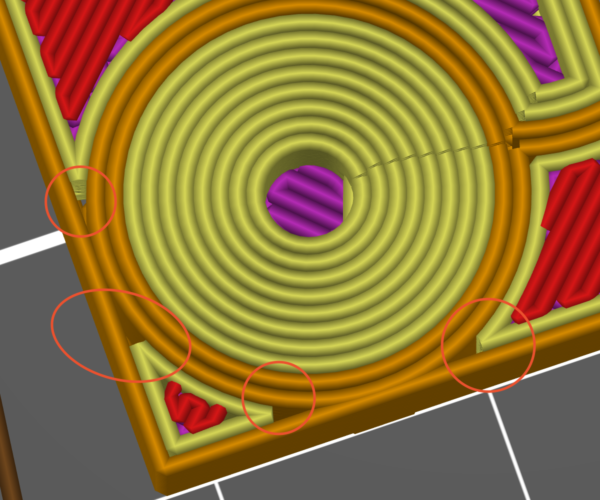

- Image 3: circular perimeters meeting a straight perimeter leave a small triangular gap. High temp improves but starts to string.

- Generally at the end of any print the finishing corner leaves a small blob, a bit like a smear.

I would like to know if any these things can be rectified.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Gaps and blobs

The excess material is probably the 1.08 multiplier. And 0.65 width for a 0.6 nozzle seems low. Nominally, about 15% larger is accepted practice. So with a 0.6 mm nozzle a 0.68 to 0.7 mm width may be better. If in doubt, set widths to 0 and let the slicer choose the correct value. And I have yet to have Prusa Slicer do a perfect job filling in every little nook and cranny. You may want to try Cura or even Simply3D and compare.

If you do find a repeatable problem that you can document with a model and gcodes and images of the problem in the final print, go over to Github and post a defect against Prusa Slicer. Devs sometimes read posts here on this peer-to-peer forum, but to be sure you get their attention takes a post on Github.

RE: Gaps and blobs

Check gap fill settings. Gaps between perimeters narrower than the extrusion width should be filled. Relevant GitHub issue.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Gaps and blobs

More info in Slicer docs. Wifi bandwidth is 50kbps, sorry I can't be more helpful.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Gaps and blobs

The excess material is probably the 1.08 multiplier. And 0.65 width for a 0.6 nozzle seems low. Nominally, about 15% larger is accepted practice. So with a 0.6 mm nozzle a 0.68 to 0.7 mm width may be better. If in doubt, set widths to 0 and let the slicer choose the correct value. And I have yet to have Prusa Slicer do a perfect job filling in every little nook and cranny. You may want to try Cura or even Simply3D and compare.

If you do find a repeatable problem that you can document with a model and gcodes and images of the problem in the final print, go over to Github and post a defect against Prusa Slicer. Devs sometimes read posts here on this peer-to-peer forum, but to be sure you get their attention takes a post on Github.

You are correct in that a smaller multiplier reduces the blob but not entirely. Also I choose 1.08 as this gave me the most accurate XYZ and wall thickness dimensions.

.65mm width is the default for prusaslicer but I will try .7 (easier to calc the wall thicknesses)

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]