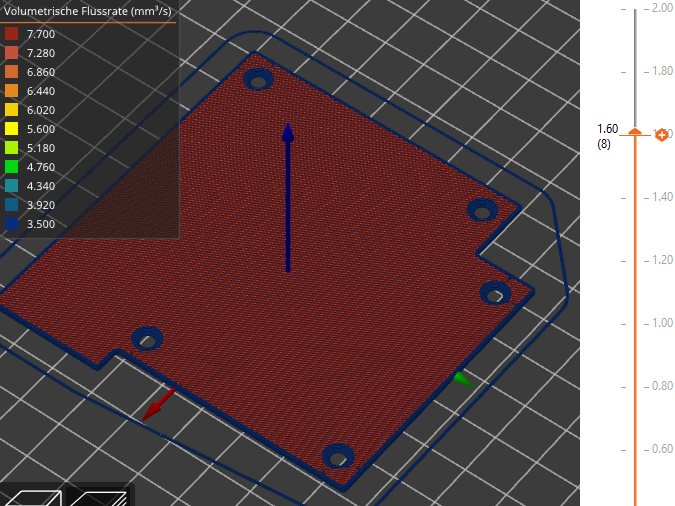

flow ratio on first full filled top layer

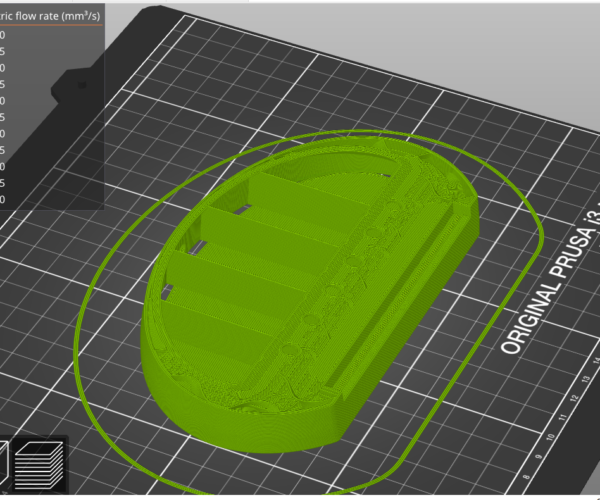

I have a problem with the flow ratio of the first full filled top layer. As you can see in the two following pictures, the flow ratio on the first full filled top layer is about twice as high as on the following full filled top layer. Is there a way to adjust this. Such a high flow ratio is too much for my 0.4mm nozzle. The flow ratio on all other layers is constant at 3.5mm3/s.

Set a max volumetric flow rate suitable for your nozzle/extruder/filament in either the filament profile or the print profile. You can set it in either place and it will use the lower value.

https://help.prusa3d.com/en/article/max-volumetric-speed_127176

Ok, I see. Thank you.

But like this the print speed is reduce to 50% for the layer. Is there no option to tell the slicer that I dont want 200% of material on this first full filled top layer. A little bit more because ther are "holes" from the infill underneath to bridge is ok, but 200%.

If this is hard coded into prusa slicer and there is no option to set it to another value, is there a wishlist for new functionality for prusa slicer?

RE: There is more than just Volumetric Flow to consider

Hi Petbel

Volumetric Flow Rate is an indication of how fast you are using filament, not as you appear to believe how fast filament is being extruded per millimetre travelled, Maximum volumetric speed, is an indication of how fast the extruder can melt the incoming filament to a consistency suitable for printing. If your printer exceeds the ability of the extruder to melt filament, the extruder will jam.

During printing, Actual volumetric Flow rate is compared against the Maximum volumetric Speed set in the slicer profile, and as the printer approaches Maximum volumetric Speed, the printer slows the print movements to maintain the ability to melt filament successfully.

Maximum Volumetric Speed, is set in 'Filament settings > Advanced' in Prusa Slicer and typically varies from 1.35 Cubic mm per second, for 'Semiflex' to 15 cubic mm per second for PLA

The values that actually affect the quantity of filament extruded per millimetre of travel are.

Extrusion multiplier (which the is used by the slicer, to calculate the expected amount of filament required based on millimetres travelled, speed of travel thickness of extrusion and width of extrusion).

and

Flow rate (Which is used by the printer firmware to change the filament extrusion values calculated by the slicer, and make them either larger (Flow more than 100%) or smaller (Flow less that 100%).

Standard Prusa profiles contain a 'Conditional' equation to affect Flow Rate.

M221 S{if layer_height<0.075}100{else}95{endif} this effectively lowers the Flow rate if the layer height is 0.075mm or thicker

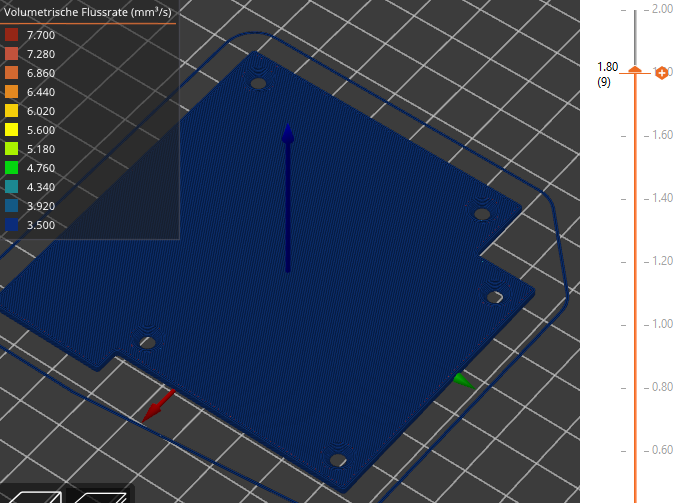

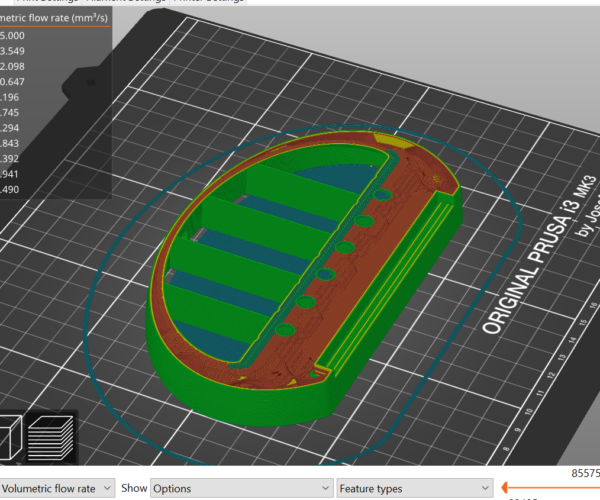

in the two images below, you can see that the volumetric flow varies significantly for the same print, dependent upon which type of filament is being printed (without changing anything else)

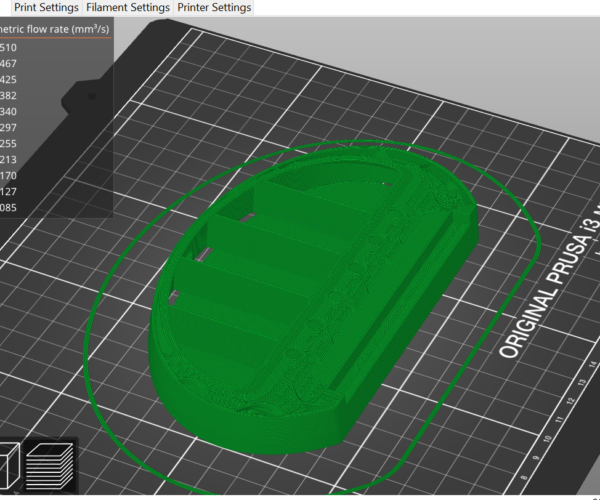

In the image below, the Filament is set to Semiflex, and all layers and features are restricted by the 'Maximum Volumetric Speed', set for that filament type 'MAX Volumetric Speed 1.35 cubic mm per second'

In the image below, the Filament is set to Prusament and all layers and features are restricted by the 'Maximum Volumetric Speed', set for that filament type 'MAX Volumetric Speed 15 cubic mm per second'

In the image below, the Filament is set to Prusament , and all layers and features are restricted by the 'Maximum Volumetric Speed', reset for that filament type 'MAX Volumetric Speed 0.2 cubic mm per second'

as above you can see that you can vary the volumetric flow rate by changing the maximum volumetric speed value in Slicer.

AND

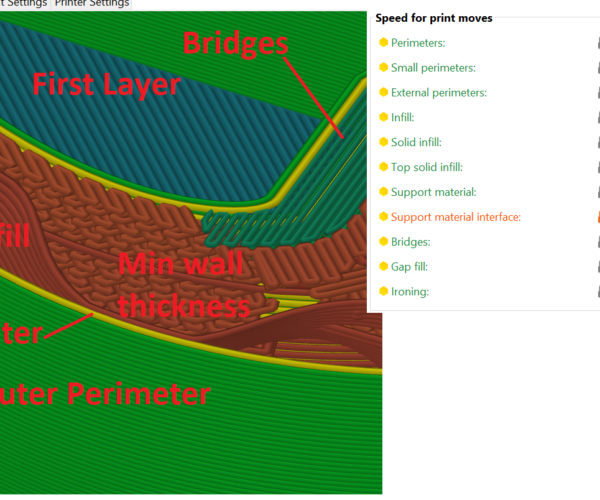

you can see that if the Maximum volumetric Speed is High enough, the volumetric flow rate can change dependent upon print speed for the various elements, as shown below in a segment of the middle image above

I hope this helps you understand what is going on.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: flow ratio on first full filled top layer

Hello JoanTabb

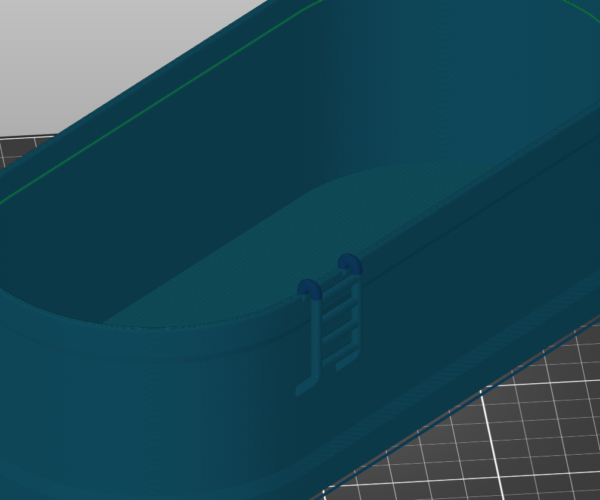

I have a such a strange phenomenon.

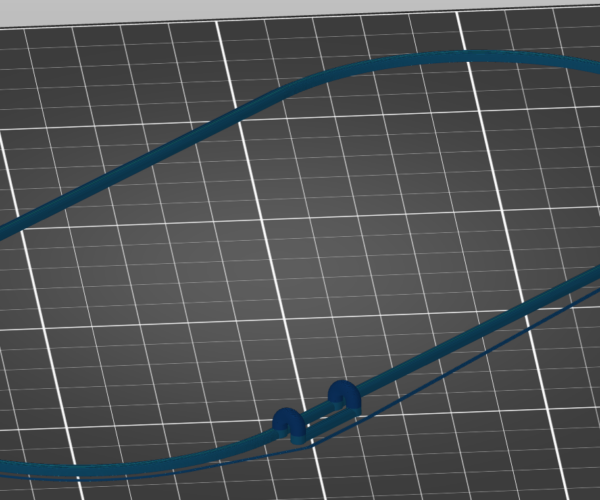

When i place the model, which i want to print in the whole size on the bed, it gives me another volumetric flow rate for the handle bars on the top of the model, than when i print only the toppes few lines:

I have also such issue, which i posted in another thread here ( https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/strange-problem-with-silk-filament/#post-611560 ) in the forum. I tried with increasing the "Speed" on "Small" and "External perimeters", i tried to increase the "Extrusion witdh" on "Perimeters" and "External perimeters", and the volumetric flow rate value are always around 0.1 to 0.4 or similar in this area. I print with 0.15mm layer heigth so i also increased the toppest layers with the "Variable layer height" to the maximum what i can set on 0.25mm.

I really can not manage to increase the voluemtric flow rate to a proper value on this few upper layers. Maybe i do not understand it completely?

Thank you in advance for your answer!

Kind

Regards

RE: flow ratio on first full filled top layer

Good Morning,

Are these handlebars the only features on the layer, when the printer slows down?

If they are the only items, the amount of time the extruder needs to be on the layer is likely to be very short, so I believe the printer slows down in order to prevent heat saturation in the filament in those areas.

This could be what is causing your issue.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: flow ratio on first full filled top layer

Hello Joan

Yes, these is the only part of the model, which are on these toppes layers.

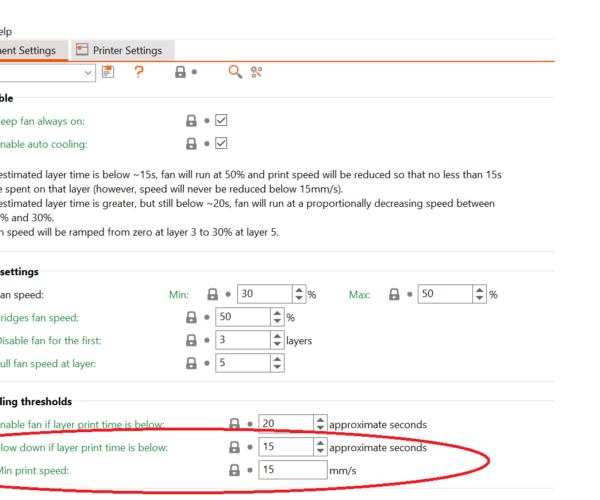

And you are completely right with your reply, this settings in "Cooling thresholds" causing this issue.

I will risk to set the "Min print speed" to 25 mm/s and give it a try:

Thank you for your fast answer!

Kind

Regards

RE: flow ratio on first full filled top layer

My Pleasure...

Sometimes we look in the wrong places to resolve issues...

Who would think that cooling settings affect print speed....

Like you, most folk would look at speed settings and flow limitations...

this is one of the benefits of the collective mind, on forums. I didn't work this wrinkle out, but I recall someone else identifying the situation... (If I could remember who it was, I would give them credit!)

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK