RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

Got it. Thanks. I'll post later results.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Hi.

101% in X and Y with 100.5% in Z was almost in the money (101.8mm real OD versus 101.6mm design). I decided to go with a bigger spur gear (137mm OD) with 100.8% in X and Y, and 100% in Z. Everything was going as planned until the filament broke and left a few minutes before attemp to reload.

Note: The filament broke at each of the last three gear samples (once).

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Good you have the dimensions down and working.

I find that when dry, may of my filaments are brittle filament and easier to snap... but I've not had a failure once loaded (but I feed via a MMU2 and that had a PTFE Tube that run to a dehydrator print box so there is no hard turns or movement from spool to print head.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

I have a dehydrator and the a Sunlu filadryer. The problem was notice on the filadryer, because when the filament broke, the filadryer was pulled and went side down to the table. I did order the PTFE tubing and connectors.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Sounds good

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Good morning. The last two trials results.

a) 100.8% X/Y and 100% Z. At 50% of the print the filament broke again. Measured the OD and was 0.8% more than design.

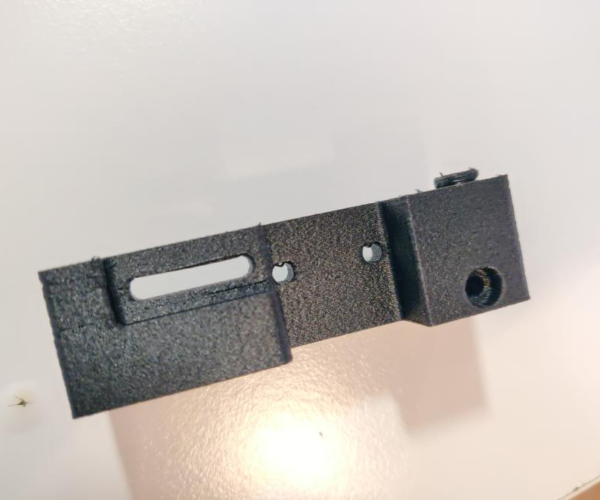

b) 100% X/Y/Z. The OD difference was 0.3% . Seems to be a bigger OD the less shrinkage factor. Original gear was 101.6mm and this gear is 136.93mm. See pictures of the bottom and top of the final print. The top finish was not so good (do not why).

Fiberlogy PA12-CF15 - Extrusion Problems

Hello together,

i found this Thread here, because i actually had an "big" Problem...

First, this is my first Spool of PA12-C15 (fiberlogy) which i am trying to print on my MK3S and my English Skills are terrible, so i hope everybody can read & understand me here.

I am trying to print PA12-CF15 for the first time, and playing around with this since 2-3 Days... but i didnt get any "nice" print.

Here some Pictures of my Problem:

As you can see, it is not always, and the layer before and after are prints fine anyway...

I already tried, more Temp on Nozzle, print faster/slower, with more or less Layerheigth & also more/less Layerwidth.

Also with Partcooling Fan & without and so on..

I'm at the end of my ideas and therefore ask for support 😀

As i already wrote, it is a MK3S with a V6 Hotend, but with a "Bit-Metal Heatbreak" from TriangleLabs & a Hardened Steel Nozzle 0.4 also from Triangle Lab

Print Settings:

260/265C Nozzle

100C Bed

Speed Between 30-60mm/s

Retract from 1-2mm (all tested)

Retract Speed 45-30mm/s (tested)

MVS Set to 5 (it is a Copy of a another PA-CF PrusaSlicer Profile)

Also tried Superslicer, but same issue.

I already put the spool for ~8h in my Food Dryer, so that i can be sure it is not Wet.

Please help me 😀

I want to print some Parts for my Voron 2.4 which i am currently Building and did not unterstand why it doesnt work on my Printer, but other People could Print this Filamenttyp & Brand also on a MK3S with a 0.4 Nozzle.

Kind Regards

Drying Time

I'm not familiar with this brand of PA-CF but 8h in a Food Dryer is not long enough. In my testing it takes over 24hours+ for a spool to dry sufficiently to print, and then you need to print from the dryer to prevent it getting too wet again.

Drying Time

Okay maybe, but the first Meters are sure dry.

And i dont think i is because it is/was Wet, because the layers before & after this issues are perfect.

it only happens sometimes in a few places and then the print works again as intended

Dry Time

I've printed many spools of ePA-CF (all eSun) and all I can tell you is it really really needs to be dry and it then prints beautifully (as you can see from early pictures). The only other big advantage I have is that I only use Tungsten Carbide Nozzles. I can't speak for the brand you have.... it may have longer CF threads that is causing an occasional and temporary partial blockage (but I'm only guessing).

Anyway, it is easy to test. Run in in the dehydrator for 24hr @ 70c and see if it makes a difference.

Drying Time

will do that, when i am @home.

but I can't imagine that.

could it also be due to something else?

how too little cooling, for example?

Drying Time

Doubt it. It really is very easy to print when fully dry. My filament is almost hard brittle and will tend to snap when you try to bend it. When I got my first role and tried to print it straight from the bag it was a nightmare (poor layer adhesion, the printed part felt spongy in parts, jams etc).

Note: I store all my filaments in a 0%RH cabinet so I don't have to dry my filament all the time but I do print it from my dehydrator as in just 2hr in a high humidity environment (eg 80% RH) it will absorb enough moisture to start to cause printing defects.

Drying Time

i will definitly try it, and put it in the food hydrator for 24 Hours.

The spool itself i store in a sealed Ikea 365+ Behalf whith SilicaGel & Hygrometer

PA-CF MK3S+

Hi. I took @jmone setup for eSUN PA-CF (I stronly suggest you try his setup) and worked flawlessly. I have a dehydrator and used it for 24H at 70C. Also, I have a filadryer to place the spool while printing (55C). Other thing I found very important is that garolite bed is perfect for CF nylon adhesion (No need of glue or tape). Hope this help.

Drying

put this in the deyhrator if i am @home.

But i have textured PEi it it hold more then good =)

Dry

Same here. Textured works well. You do have to keep it dry.

put this in the deyhrator if i am @home.

But i have textured PEi it it hold more then good =)

--------------------

Chuck H

3D Printer Review Blog

Drying

I ran a multi month experiment (the thread is somewhere on the forum), with filament samples to see how long it takes them to absorb and lose water in various conditions. You may be surprised to see how hydroscopic PA is.

Moisture Gained in 80% RH Environment

- PLA : Gained a max of 0.53% in 5 days then stabilised at this level

- PETG : Gained a max of 0.40% in 8 days then stabilised at this level

- ePA-CF: Gained a max of 4.88% in 1 month then stabilised at this level (and hit 0.2% in only 2 hours and 0.6% in 8 hours)

Drying Filament in a Dehumidifier at 50c for 24hours / then increased to 70c till "dry"

- PLA : 0.11% (note: stabilised at 0.11% at 15h) / another 4hrs @ 70c till 0%

- PETG : 0.12% / another 10h @ 70c till 0%

- ePA-CF : 1.75% / another 48h @ 70c till 0%

Summary

It takes a looong time to dry ePA-CF and it gets "wet" very quickly. Also of interest is that storing a ePA-CF in a freezer bag with desiccant (being changed) could only achieve a dryness of 0.56% gain after 11 weeks in my room (and it tended to move up and down with the RH of the room) which is wetter than PLA/PETG ever got even in a 80%RH environment. So even with ePA-CF stored with desiccant it will require active drying (say 8hrs @ 70c) prior and during to printing and from my experience brand new spools out of the bag are much wetter than this (so the first dry needs to be at least 24hrs @ 70c).

Dryed over 24H

I dryed my PA12-CF now over 24h with 70C in the Food Dehydrator, and printed it again from my sealed Filament Dry Box with SilicaGel in it.

Same issue 🙁

Have no ideas anymore 🙁

To be honest, I am very desperate because it works for others

Layer Skip

Are the skipped layers always in the same place or is it random between prints?

Slow down

I dryed my PA12-CF now over 24h with 70C in the Food Dehydrator, and printed it again from my sealed Filament Dry Box with SilicaGel in it.

Same issue 🙁

Have no ideas anymore 🙁

To be honest, I am very desperate because it works for others

This filament is not easy to print. Keep it dry and keep trying. You may need to tweak you settings a little more and slow the print down.

--------------------

Chuck H

3D Printer Review Blog