Enhancement Request - Allow setting an extruder number for Support Interfaces

BACKGROUND

I'm constantly trying to improve quality of the finished product, yet speed up handling time. When printing with an MK3S+ and MMU2S, you could have your main material on #1, but then instead of having a water soluble material on #2 and have the slicer use #2 for all of your supports (which is an expensive material).

PROBLEM

When using supports in Prusa under Print Settings | Multiple Extruders, you do not have an option to assign support interfaces separately from what is assigned to supports. The support interface is just lumped into the same option under "Extruders". This means the entire support structure, rafts, skirts, AND interface have to printed with the same one, causing you to use the more expensive water soluble material for everything to do with supports.

PROPOSED SOLUTION

You could instead assign a 3rd material used JUST for the supports (one that is cheaper than water soluble material), and assign the water soluble material just to the proposed separate option "Support Interfaces", that small area that attaches the supports to the main print.

BENEFITS

Now when your print finishes and you give it a water bath, the water soluble will dissolve at the interfaces, leaving behind only your finished print and a bunch of support structures that can just be recycled.

This achieves having supports where needed, yet having a cleanly removed interface, BUT not costing too much because you were forced to print that water soluble material for the entire support structure.

JUSTIFICATION

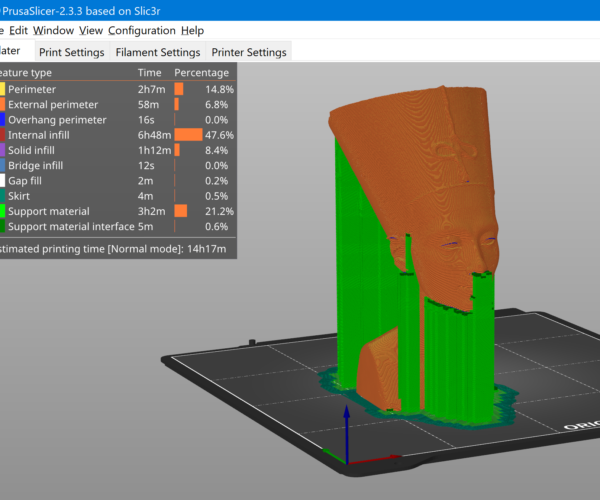

Water soluble material is not cheap, costing 5-7 times as much as other materials that would be just fine for support structures, In the second image, I used a simple example of where you might have supports turned on (although not the best example as the back of Nefertiti's head prints just fine without supports). Notice in the report of the "Estimated printing time" that you get at the top left, you can see that Prusa knows the difference between "Support Material" and "Support Material Interface".

And in this example the savings would be quite a lot of material. Though I can't provide the percentage of support materials by weight, I can take a stab based on printing time percentages. Total weight is 133.39 grams over 14 hours and 17 minutes (857 minutes). You can see in the report that Support Material is 3 hours and 2 minutes with the support material interface being 5 minutes, and skirt 4 minutes. If you were to assign #2 to "Support Materials", it would be all three of those (and any rafts if used), so 3 hours and 11 minutes (191 minutes), which is 22.3% of the total time and if applied to the weight Supports would be 29.7 grams.

Currently, if I were to use a water soluble material in my MMU2S along with another material for the main part of the print, I would have to use 29.7 grams of the water soluble material. **1. If Prusa added this enhancement allowing me to assign a water soluble material ONLY to the Support Material Interface, I would save a lot of money over time and we could recycle the support structure that would now be in plastic that doesn't get flushed down the drain, only using a tiny amount of water soluble at the point of contact (interface). In this example we would go from using 29.7 grams of material (5 minutes worth which is only 0.58% of the total or 0.77 grams out of 133.39 grams). Decent Water soluble filament costs around $140 per 1KG. In this example to print all supports out of water soluble would cost around $4.16 ($0.14 per gram x 29.7 grams) versus if we only had to use this material for the interface would cost around $0.11 for interface (0.77g x $0.14) and rest of the supports printed out in a $20/KG filament or $0.56 (28.03g x $0.02)

for a total support cost of only $0.67 versus $4.16 with the current way. Plus have the option to recycle the remaining support structures of 28 grams (versus the current way would have all of that going down the drain, along with $3.50 of your hard earned money. Multiply this thousands of times over for a single printer farm and you have a sizable cost savings here with a splash of ethical manufacturing (recycling as much waste as you can).

**1 - Note: I don't know another way to draw conclusions from the break out that shows the printing times for each feature type. But the point is still made that the interface is a very small part of the supports and if we could focus water soluble just at that point, we could save a lot of money and waste (water soluble goes down the drain, you can at least recycle the support structure pieces if they were separate from the interface)

ATTACHMENTS

RE: Enhancement Request - Allow setting an extruder number for Support Interfaces

First of all welcome.

Second , this is a user to user forum. Dev's do occasionally pop in but not often. All bug reports and feature requests need to be made at the Prusa Slicer github site https://github.com/prusa3d/PrusaSlicer/issues?q=is%3Aissue+is%3Aopen+sort%3Aupdated-desc

Please read the new issue guidelines there fully before posting and please do a search of both OPEN and CLOSED issues there before posting. Given that there are ~1700 open posts already. In fact I have a vague memory of already seeing a request almost identical to this already.

Maybe it was this one https://github.com/prusa3d/PrusaSlicer/issues/3397 ?

RE: Enhancement Request - Allow setting an extruder number for Support Interfaces

Got it thanks. I did do a search here, but didn't find anything. I did not know about using their GitHub repo for things like this, so thank you for that. Interesting that someone else mentioned it 2 years ago, and yet still nothing. Must not be much request.

Are most people just printing supports with everything being water soluble for supports? That article you sent me to, only pointed out a 1/3 saving's, when it is actually closer to 6-7 times (on the support costs). The overall savings depends on how much of the total weight of the print is supports obviously. My focus was on savings when you do use supports. Because from a business standpoint, I buy the consumables and have to make sure my business model charges accordingly. To be more competitive on pricing, your price needs to be lower, and when looking to maintain the same level of quality things like this stand out as a no brainer.

BTW, this issue will be even more important once people have invested $4,000 in a 5 tool head XL. And we are only talking a small development change. All of the needed pieces are already in place (they already have a separate field for "Support Material Interface".

Any way, have a great day, glad to be here, reading through a bunch of material this weekend 🙂