Dual Extruder - Independent Temperature Control for Nozzles?

Hi.

I am a big fan of the prusa slicer, and a long time owner of an i3mk3s+ (with mmu2s) -- soon to be upgraded to an MK4. While I love my mk3s+, and the whole Prusa "philosophy", it is not my only 3D printer. I also have a Snapmaker a350t, recently upgraded to a dual extruder. I have tried their slicer, and hate it. I tried Simplify 3D, and was very disappointed with their implementation of dual nozzle printing. I then tried my favorite slicer -- Prusa Slicer, which actually has a profile for the a350 -- which was great. I did a slight modification for that profile to add the 2nd extruder... and it works surprisingly well... but there is one problem: it doesn't seem to allow me to control the temperature for each nozzle independently. The temperature is set on the "Filament Settings" tab, with no override in the "Extruder 1" and "Extruder 2" sections of the "Printer Settings" tab. I have media I wanted to combine into a print... but one has a sweet spot of about 200c and the other about 215c... I cannot get them to cooperate.

I find this to be a strange oversight... am I missing something?

Thanks!

RE: Dual Extruder - Independent Temperature Control for Nozzles?

Feels actually logical to me. More likely than not you'll have different filaments in each extruder, so the temperature would be defined by the filament you assigned to each extruder.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Dual Extruder - Independent Temperature Control for Nozzles?

You can only set this once under the "Filament Settings", and it applies to BOTH nozzles. The problem is that they do not appear to be able to be set INDEPENDENTLY.

It is entirely conceivable that a person might want to run two different filaments with differing optimal melt points. What I want to know is there a (hidden) way to control the temperature of each nozzle indepently, so I can run one at say, 200c, and the other at 215c?

RE: Dual Extruder - Independent Temperature Control for Nozzles?

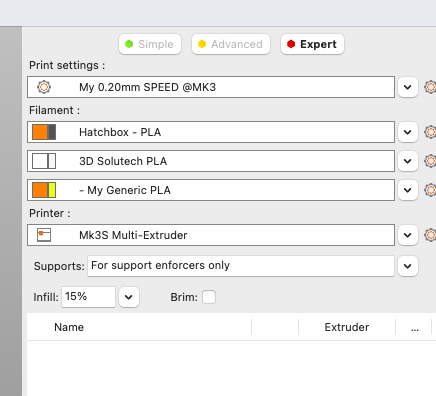

Totally possible that I'm somehow misreading your question… If you have configured multiple extruders, you can assign a different filament (with different temp) to each from the drop down menus. Doesn't that accomplish what you're trying to do? Here's an example for three extruders, with a different filament assigned to each.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Dual Extruder - Independent Temperature Control for Nozzles?

I see what you saying fuchsr... Hmm... I will have to fiddle with this a little bit. When I tried that, I was carrying over the settings when prompted... perhaps that was mistake...

What I was doing:

I Set the first extruder to PLA200, which is set to print at 200c -- and that is fine. But when I set the 2nd extruder to PLA215 at 215c, I'm prompted to carry over the settings, I say YES, then it overwrites the temperature on the "Filament Settings" Tab, and it appears to apply 215 to BOTH nozzles.

But I will try saying NO, and see where that gets me.

Thank you for the insight! I'll post back with my results.

RE: Dual Extruder - Independent Temperature Control for Nozzles?

One problem I have with how PS handles dual extruders is it heats the inactive extruder up to temp immediately even when not needed. This is even with the ooze prevention offset active. I have to manually modify gcode each time.

RE: Dual Extruder - Independent Temperature Control for Nozzles?

Trying to get to the bottom of this. Let's say you have a filament profile "PLA220", with temp set to 220. Now let's change the temperature to 200. Click on the Save icon (looks like a floppy disk—if you're old enough to remember 🙂) next to the profile name. The Save preset dialog will pop up; rename it to PLA200. You should now have two filament presets, one PLA200 and one called PLA220. Now back to the 3d Editor View. On the right side, the drop down menus under Filament should show you the PLA200 and PLA220 preset, and you can assign each to a differen extruder. You should only be prompted to overwrite a preset if you hadn't saved it before. But you do need to save it first, or it won't show up in the drop down. Hope that helps.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Dual Extruder - Independent Temperature Control for Nozzles?

That's how it works for me. I wish there was a standby temperature option. In my case if T0 is the active extruder set to 220 then T1 will heat to 200 even though it's not yet needed. That leads to oozing and possible contamination of the print

Trying to get to the bottom of this. Let's say you have a filament profile "PLA220", with temp set to 220. Now let's change the temperature to 200. Click on the Save icon (looks like a floppy disk—if you're old enough to remember 🙂) next to the profile name. The Save preset dialog will pop up; rename it to PLA200. You should now have two filament presets, one PLA200 and one called PLA220. Now back to the 3d Editor View. On the right side, the drop down menus under Filament should show you the PLA200 and PLA220 preset, and you can assign each to a differen extruder. You should only be prompted to overwrite a preset if you hadn't saved it before. But you do need to save it first, or it won't show up in the drop down. Hope that helps.

RE:

Trying to get to the bottom of this. Let's say you have a filament profile "PLA220", with temp set to 220. Now let's change the temperature to 200. Click on the Save icon (looks like a floppy disk—if you're old enough to remember 🙂) next to the profile name. The Save preset dialog will pop up; rename it to PLA200. You should now have two filament presets, one PLA200 and one called PLA220. Now back to the 3d Editor View. On the right side, the drop down menus under Filament should show you the PLA200 and PLA220 preset, and you can assign each to a differen extruder. You should only be prompted to overwrite a preset if you hadn't saved it before. But you do need to save it first, or it won't show up in the drop down. Hope that helps.

Yes! That is exactly what I did (based upon your previous advice). It seems to be working! Thanks! I guess I was conceiving of how to do this more like simplify3D handles it, but this is just fine.

One problem I have with how PS handles dual extruders is it heats the inactive extruder up to temp immediately even when not needed. This is even with the ooze prevention offset active. I have to manually modify gcode each time.

That really would be nice... Is there a place to suggest that for future releases?

RE: Dual Extruder - Independent Temperature Control for Nozzles?

Is there a place to suggest that for future releases?

Sure. It's the Prusa3D github site https://github.com/prusa3d

I haven't checked but IIRC there are open tickets for this already.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Dual Extruder - Independent Temperature Control for Nozzles?

I think once the XL toolchangers are out this area will get a lot of attention. Expect it to be working well then as people will look to manage different material temps and multi tools with a view to efficient changes whilst ensuring quality.

RE: Dual Extruder - Independent Temperature Control for Nozzles?

I have a related issue with my Snapmaker A350 and thought maybe others in this thread have already solved it. The PrusaSlicer profile unfortunately hasn't been updated since before the dual extruder started shipping... and it needs work. Specifically:

When a print starts, it does not set the active extruder before it begins heating. Thus, if the right extruder is currently active (cause you just changed the filament for instance), it will heat up the right extruder... even if the print is going to start with the left one. It makes it all the way through the priming sequence before switching to the left extruder and tries to start the print with it cold. If I set a high standby temperature it will be able to print, but it also doesn't wipe the right extruder so all that filament that oozed out of it is now dragging through the skirt and messing everything up. I know that T0/T1 can be used to switch extruders, but how do I know which one will be used first? so I can update the start gcode. Trying to search for this only brought me to this forum thread.