RE: Draft shield improvements

Can you use the Pause command (Not sure if this works on a Mini) tack the shield back in place with Hot Melt Glue, then resume printing, and use IPA to release the hot melt glue at the end?

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Draft shield improvements

I've worked around this by increasing the number of loops in the draft shield. Works quite well for large/tall prints.

RE: Draft shield improvements

If you keep the distance from object small ie 1mm and have some support. The skirt will sit on the support first layer. I have not figured out how to make this work unconditionally but it certainly work in this example

RE: Draft shield improvements

@joantabb

Joan, Thanks for the idea of the hto glue. I will have to try this. I have used the shied with some shorter prints but I need to use it on soem tall prints. This might be just want I am looking for.

--------------------

Chuck H

3D Printer Review Blog

RE: Draft shield improvements

Can I request the ability to add a brim to the Draft shield?

Workaround for Draft shield with brim:

1. Activate Draftshield with 5 loops; distance from object 1mm -> slice; save Gcode with bottom in Name

2. Activate Draftshield with 1 loop; distance from object 2mm -> slice; save Gcode with top in Name

3. open both gcodes search for ";BEFORE_LAYER_CHANGE"

find:

;BEFORE_LAYER_CHANGE

G92 E0.0

;0.4

;WIPE_START

4. in bottom.gcode: coppy everything above ;WIPE_START

5. in top.gcode replace everything above ;WIPE_START with the code from bottom.gcode ->save

6. print top.gcode.

ps: pure PC is horrible to print and even with enclosure needs a draft shield with a raft.

thanka

Can I request the ability to add a brim to the Draft shield?

Workaround for Draft shield with brim:

1. Activate Draftshield with 5 loops; distance from object 1mm -> slice; save Gcode with bottom in Name

2. Activate Draftshield with 1 loop; distance from object 2mm -> slice; save Gcode with top in Name

3. open both gcodes search for ";BEFORE_LAYER_CHANGE"

find:;BEFORE_LAYER_CHANGE

G92 E0.0

;0.4;WIPE_START

4. in bottom.gcode: coppy everything above ;WIPE_START

5. in top.gcode replace everything above ;WIPE_START with the code from bottom.gcode ->save

6. print top.gcode.

ps: pure PC is horrible to print and even with enclosure needs a draft shield with a raft.

Wow, this seems so obvious but I didn't consider this method, thank you!

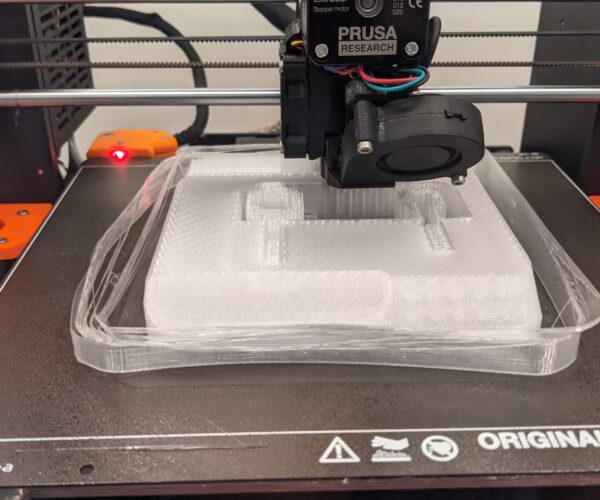

I'm trying to print some ASA parts, and I need a draft shield and brims around the actual objects inside. I need the draft shield to also have a brim to stop it from detaching mid print, which *is* a problem I've experienced.

I figured this would be easy in Prusaslicer, but I couldn't make it work and when I searched, I found myself here.

It's disappointing that this feature isn't available inside the software, a checkbox with "Add brim to draft shield" would solve the issue for me, although the ability to set loops and so on would probably be useful for others as well.

I'm a developer myselt, but with a hatred for Java so normally I'd look and see if I could provide a patch + pull request for a feature, but I'm sitting here psyching myself up to look at the source for it.

In the meantime, I'm probably just going to knock up a python script to automate this procedure, whole not as nice as being able to do it inside the slicer software, it will make it less painful.

If you set your draft shield to say 5mm away from your part and your brim to 10mm then the brim will go under the draft shield and outside it by 5mm. At least with PS2.3. The draft shield is printed into the brim so the brim will stick to it and hold the shield down.

Its not quite as nice in PS2.4 (depending on your POV) as the draft shield 'cuts' into the brim. I supposes 2.4 is correct in that you dont get a double extrusion like you do with 2.3 but both will work.

Theres no hacking of gcode required.

Works in *some* situations.

If you set your draft shield to say 5mm away from your part and your brim to 10mm then the brim will go under the draft shield and outside it by 5mm. At least with PS2.3. The draft shield is printed into the brim so the brim will stick to it and hold the shield down.

Its not quite as nice in PS2.4 (depending on your POV) as the draft shield 'cuts' into the brim. I supposes 2.4 is correct in that you dont get a double extrusion like you do with 2.3 but both will work.

Theres no hacking of gcode required.

This will work in some situations, but may not be ideal, and not in the specific situation I have here because the top of the model(s) (there are multiple instances on the build plate) has a larger diameter than the bottom of the part, so a brim would have to be considerably larger than it needs to be to make it run into the draft shield.

The ability to add a brim to the draft shield would be a far better solution.

If I was printing that many parts that warrant using a draft shield then I would use an enclosure (I do, so don't need to use a draft shield) in 99% of cases. Further to that if there were specific circumstances where I did need one and wanted a brim on it then its only a few minutes work to actually model something suitable.

I get that people really like to do everything in one bit of software but sometimes there no substitute for working outside the box and using a tool more suited to do the exact job you want. Its the same difference between using the slicer generated supports and just designing your own into the model. Doing your own is way more efficient, especially if you end up printing more than a 1 off.

RE:

This actually led me to a decent solution. Some options may have been improved since this was discussed, but:

-Raft Layers: 1 min

-Raft expansion: ~4mm, whatever gap you'd like

-Draft Shield: Enabled

-Distance from Brim/Object: ZERO (it counts the raft as the object)

This will essentially build your part inside of a little bucket.