Disable Bridging?

I'm trying to print a project (photo's below) that has a 10cm x 5cm section that requires support. In the past I have printed it in Cura with supports and it printed out just fine. However in PS2.3.3 it insists on bridging the entire area and the resulting quality of the print is terrible.

I have enabled supports (and unticked 'don't support bridges') in the print settings but it still prints like garbage. Stepping through the print in the software I can see that the support material stops 3 layers before the area that needs supporting so is actually appears to be doing nothing at all...

I know I can just continue to use Cura but I prefer PS and would like to make it my go to slicer. Am I doing something wrong? Is there a way to turn bridging off for this project so I can get a decent quality print?

Edit: My images don't seem to be appearing (although they do for me when editing) - not sure what's up with that?

Without more information, it's impossible to help. If you save your project from Prusaslicer as a 3mf file (File/Save as), ZIP it (important, you can't upload the 3mf without zipping it), then attach it to your post, this way we can check all your settings to see what's going on.

3mf file

Yes without the 3 images I attached being visible there isn't much to go on. Hopefully I've successfully attached the zip to this post though. Thanks.

RE: Here's another stab at getting the images to appear.

This is how the print comes out.

This hopefully shows the support material stopping a few layers short of where it needs to be.

This one shows the area that needs supporting (view is from underneath the bed looking upwards).

Not sure I'm following. When I open the 3mf file, it clearly generates supports for that area. And yes, of course there will be a gap between the top of the supports and the first surface area or else the supports would be inseparable from the object. The only thing I see is that I would change the bridging angle in Print Settings/Infill to 90%. For some reason Prusaslicer prefers the longest distance rather than going across. This may give you a nicer looking surface. I would probably also increase the z distance of the supports a bit, to make them easier to remove.

One last thought. I don't know how this model will be used but what you're currently trying to support looks like the visible outside. I would try flipping the whole model by 180 degrees. Sure, more supports are needed but that looks like the inside of the model so who cares about looks. Would put support blockers around the small round openings that look like they're used for press-fit, so they don't get filled with hard-to-remove supports.

One more thought... Not sure why you're using 0.16mm layer height. There's really no horizontal detail here, so models like this I would print with 0.3mm layer height and save myself almost 2 hours. Or even use a 0.6 mm nozzle and 0.4mm layer height.

...

The inside is actually more important than the outside as it will be filled with cogs and gears so it needs to be accurately printed hence the reason it's arranged the way it is. My photos are awaiting moderation so if you come back when they've been approved things might be clearer when you see the quality of the print.

Supports are indeed generated but there's a clear gap between where they end and where that overhanging layer starts. When the model is printed the support material makes no contact whatsoever with that layer and you can see the overhanging edge has sagged in the resulting print leading to several loose strands of filament being visible along the leading edge.

I just tried changing the bridging angle to 90 but all that has done is make it bridge across the narrower cross section. I don't want it to bridge at all - I don't understand why it is insisting on printing like this as to my mind at least this is not the best way to print this part of my project?

Good point about the layer height - I had just left it set at the default, will change it on the next print.

Contact Z distance

While it might not seem right, but in your issue the Contact Z distance is calculated "correctly", as the slicer (PrusaSlicer, Slic3r) generates a bridge line as round, rather than the other lines as rectangle with semicircular ends.

Check the height view and you will see that in the slicers mind, it would print perfectly.

The slicer generates the lines with a higher volumetric flow compared to other lines on the same speed, because of the round lines, so in most if not all cases, we lower the bridge flow so that it is closer or lower than the other lines, in order to print well.

A fix would be to either generate the bridge lines as any other lines (rectangle with semicircular ends), so that the line height is the same as any other lines on that layer, or to lower the line height of the bridge lines to the same on that layer (which would shrink the width too).

I tend to side with the second one, but until someone point me to the part of the code that controls this (posted about this not too long ago) or someone codes it and try both of them out, we can't tell which is better or worse.

Supports are poor in PrusaSlicer (for now)

PrusaSlicer supports are one of the few remaining weak areas. The development team is apparently working on them for the next release. The problem is that the original Slicer code base builds a bridging layer below to supported surface, and that tends to look stringy. I looked into this and there were historical reasons for it, but 3d printers have improved.

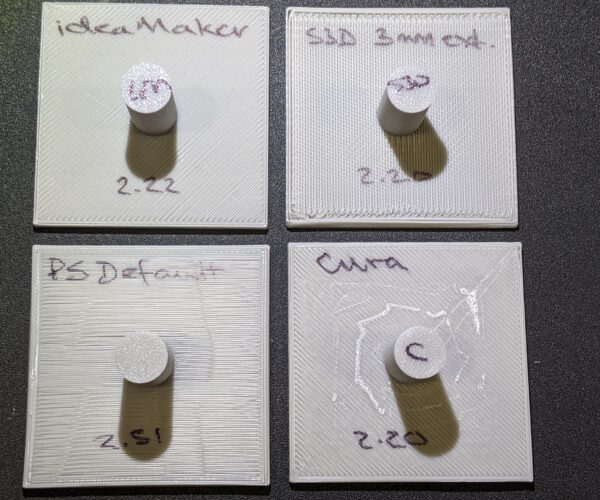

Here's a comparison of a 50x50x2mm supported surface sliced using 4 different popular slicers (ideaMaker, Simplify 3D, PrusaSlicer, and Cura);

Notice that the PrusaSlicer underside is not only stringy, but ~0.3mm thicker.

Notice that the PrusaSlicer underside is not only stringy, but ~0.3mm thicker.

I'm eagerly awaiting the new release. For now, I use ideaMaker for prints with large supported areas.

RE: Disable Bridging?

That's the way PS does supports and bridging. There are several threads comparing several slicers and unfortunately PS comes out about the worst for that sort of feature. Check out https://forum.prusa3d.com/forum/prusaslicer/why-is-the-prusaslicer-support-so-bad/

or https://forum.prusa3d.com/forum/prusaslicer/using-support-messes-up-the-part/

While PS2.4 is supposed to be tackling support issues we will have to wait and see just how much in the way forward it takes. Until then you aren't going to get anything near the Cura result.

PS makes the assumption that the plastic will not touch the support (unless you are using soluble supports so contact distance=0). As such it also assumes that the filament is not squished against any layer below it. So all supported areas/bridges/bridge infill are printed with a cross section of the nozzle diameter/extrusion width and NOT your selected layer height. That means for a 'normal' 0.4mm nozzle that those layers are planned with a 0.45 mm layer thickness. With a 0.6mm nozzle its even more noticeable.

So the gap between it is the planned contact z distance PLUS the thicker layer that assumed to be printing. It results in less than optimal surface results for those under areas. Even if you turn off detect bridging that only removes the assumption for the perimeters which then go back to your layer height, it doesn't stop the bridge infill being your nozzle width in height. At the moment there is literally no way to alter this.

RE: Disable Bridging?

Thanks for all the replies guys, whilst obviously not what I wanted to hear at least I can take comfort in knowing it's not my fault!

I'll have to continue to use Cura for stuff like this for the time being and patiently await 2.4!

If all Prusa did in the new release was improve supports, they might as well call it v3.0, such a difference it would make. By careful use of paint on supports you can rein in the super aggressive supports algorithm to some extent, but it's just such as pain in the rear end.

PrusaSlicer is steadily improving. I'm impressed.

If all Prusa did in the new release was improve supports, they might as well call it v3.0, such a difference it would make. By careful use of paint on supports you can rein in the super aggressive supports algorithm to some extent, but it's just such as pain in the rear end.

I think we take PrusaSlicer for granted sometimes. The strides they've made in the last 18 months are impressive. Almost every one of the features that kept me going back to other slicers has been addressed. Once they do their usual revamp of slicing, I'm going to have very little reason to open another slicer. They could easily call it v12 by now if they cared about the marketing.

Not to say the other slicers are slouches, but Team Prusa has upped the game quite a bit. I'm pleased to see Ultimaker working on the Arachne engine for Cura, and Raise 3D's wall texturing for ideaMaker still give them some differentiation.

RE: Disabling Bridging

So, I forcibly disabled bridge generation in the slicer code, which made the slicing 10 times slower... lol,

but at least it was able to generate a useable gcode without a bridge.

(If I'm allowed to upload that gcode, then anyone can check it out in the PS gcode viewer.)

While I obviously didn't made an all around solution to disable bridge generation, but at least it seems possible to do so.

Edit: "Sorry, you are not allowed to upload files."

Disabled bridge

Here is an "image" of it: https://imgur.com/gallery/UcvnoED