Better results for slanted tops

Hi,

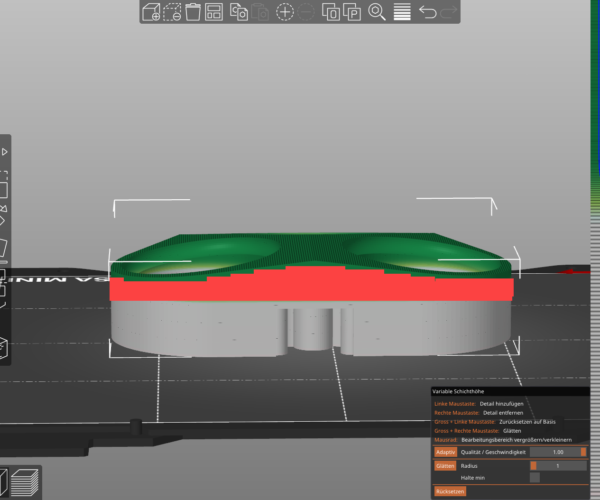

I have to print a part (25mm hight) with a top with 3 different angles (please see picture).

If I print it with 0,20 layer hight it takes round about 3h 30m but the top is very "stairy".

I tried it with a other layer hight from 15mm to 25mm. This increase the time to round about 4h 30m.

Is there a way to get better results for the top without this enormous time increase.

I saw the feature "Extra perimeters if needed" but I think this will not help in my case?!

Best regards

Chris

Best Answer by Lize:

This is a good example of the usefulness in altering the layer height across the model. Have a search for a video about "variable layer height" if you can't understand this description.

On the Plater view in slicer:

- Set your layer height using the usual method to the height you require for the majority of the model

- The click the "variable layer height" button in the top bar (the icon is horizontal lines thick to thin)

- A grey column of lines then opens to the right of the sheet view and a small pop up window at the bottom

- Click and hold the mouse on any part of grey lines you want to change the height, so in your case at the top of the column

- Left click will reduce the layer height and right click will increase it

- You'll see the colour of the model on the sheet altering to show the layers

- There is a reset button in the pop up type window so you can start again

Perimeters will alter the outside vertical walls before the infill so not what you need in this case but its useful to increase this number for extra strength of a print without having to necessarily increase infill. Its all a bit of a balance as depending on the print increasing the perimeters can make the print time a fair bit longer than you might expect. Another thing you can have a read up on is modifiers, it won't help you in this case either but you can change specific areas with these, like altering infill pattern and percentage or perimeters to make sections stronger without increasing time too much.

RE: Better results for slanted tops

No that setting is not for this. Have you tried using the variable layer height function ? Which is what this is for.

btw a 4 hour print is short. When you get up to 40 hours then complain lol.

RE: Better results for slanted tops

This is a good example of the usefulness in altering the layer height across the model. Have a search for a video about "variable layer height" if you can't understand this description.

On the Plater view in slicer:

- Set your layer height using the usual method to the height you require for the majority of the model

- The click the "variable layer height" button in the top bar (the icon is horizontal lines thick to thin)

- A grey column of lines then opens to the right of the sheet view and a small pop up window at the bottom

- Click and hold the mouse on any part of grey lines you want to change the height, so in your case at the top of the column

- Left click will reduce the layer height and right click will increase it

- You'll see the colour of the model on the sheet altering to show the layers

- There is a reset button in the pop up type window so you can start again

Perimeters will alter the outside vertical walls before the infill so not what you need in this case but its useful to increase this number for extra strength of a print without having to necessarily increase infill. Its all a bit of a balance as depending on the print increasing the perimeters can make the print time a fair bit longer than you might expect. Another thing you can have a read up on is modifiers, it won't help you in this case either but you can change specific areas with these, like altering infill pattern and percentage or perimeters to make sections stronger without increasing time too much.

RE: Better results for slanted tops

A simple way to think of layers is stack bricks. You can stack 12" bricks and get certain angles, or you can stack 2" bricks to get finer angles. This image is from another post, but shows how layer height and angle/roughness relate: where a smaller layer height yields smoother angled surfaces. But you really can't expect an FDM printer to makes perfectly smooth near horizontal angles. As Lize said, variable layers might help as a compromise between print time and final quality.

RE: Better results for slanted tops

Hello @lize,

thanks for the detailed answer. I'm relativ new with 3D-Printing overlooked this function.

It`s much easier to use than to define manually the layers hight as I done, but in the end it is the same (I think).

My hope was that is possibel to set the layer hight only for the top ... somthing like ironing for areas with an angle,

so that I can avoid the detailed layers in the below picture in red.

The third area, which is not shown on the picture has an greater angle, so I have to go in this "depth" .

'

BR

Chris

RE: Better results for slanted tops

@neophyl

Thanks for the tip. The problem is that I want to print a lot of them, so 50 h in the end is nothing.

And this is only one part of the complete product.

So every minute counts ;-).

BR

Chris

RE: Better results for slanted tops

I know what you mean about an ironing idea but as Tim says the nature of FDM means you'll always get steps like you do layer lines on vertical faces, using a lower layer height just means that more shallower steps to achieve the same gradient and so they look less obvious.

I've recently been doing a large flat piece which is a gentle slope with cutouts creating steeper angles. It wouldn't fit on the print bed in one piece anyway but I've broken it down into sections and printed the steeper more detailed sections at low layer height to aid post processing and the rest with the gentler slope at 0.3. The 0.3 is very stepped but I was always going to be using filler to smooth the whole thing out so opted for the time saving.

When I first got my printer I found myself trying to shave off time on small to medium sized prints but in reality once I got more in the swing of it saving an hour or so became less important especially if quality was a concern. What can be useful is printing a small a cross section of a larger item to check the design in practice before setting off a detailed/quality print of the whole thing.

Time can be an important factor, I'm currently printing of a lot of small items in batches which in total will be in excess of 350 hours so with this project any fine tuning I can do helps a lot. For example I've turned off Gap Fill (the white sections in the sliced view) which saves about 9 minutes in a 2 hour batch, doesn't sound a lot but overall it'll reduce printing by about 30 hours and the print quality is unaffected.

RE: Better results for slanted tops

Save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations. While you can't eliminate the "stairstep" effect with FFF printing, you can minimize it. Unfortunately, the best solution depends on the specific model you're printing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Better results for slanted tops

@Chris, not sure my last reply makes entire sense given your note about printing a lot of them and the 50hrs. I'd swear it wasn't there when I replied but likely I must have skipped passed it!