Avoiding solid topfill under pegs on a slab?

I find that when I have a model with a solid slab with any kind of peg or post sitting above it, if the peg is too small then PrusaSlicer will fill the area under the peg with solid infill and then print the peg on top of the solid infill. For wider pegs, the slicer will behave as if the peg is a continuation of the model (not sure the best way to describe that; see image) and continue the infill as if it's a single object.

I'm finding that the printing behavior for smaller pegs tends to introduce weakness (at least in PLA) that can cause the pegs to snap off fairly easily compared to the behavior for larger pegs (though maybe I'm deceiving myself and it's just the size of the peg here? 🤷♂️). Is there a slicer setting I can use to change this behavior?

Best Answer by jseyfert3:

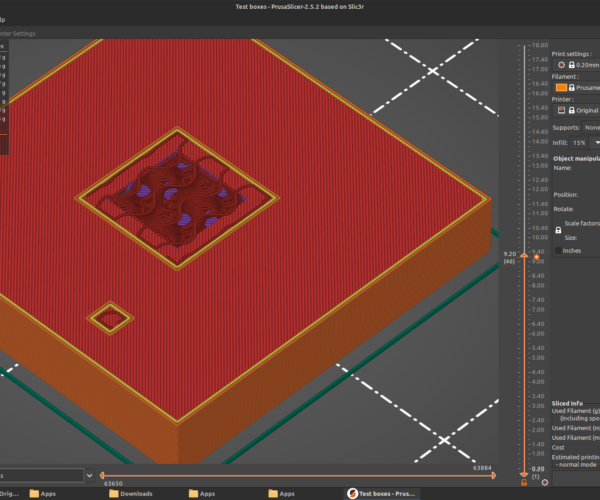

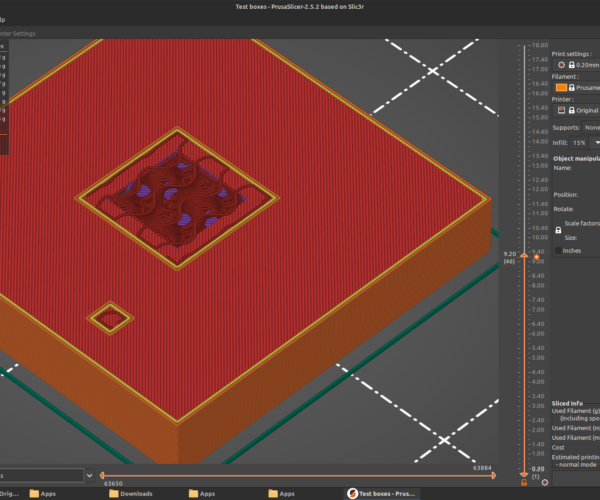

Try the 2.6 alpha release. In 2.5.2, I get this, which looks like what you have:

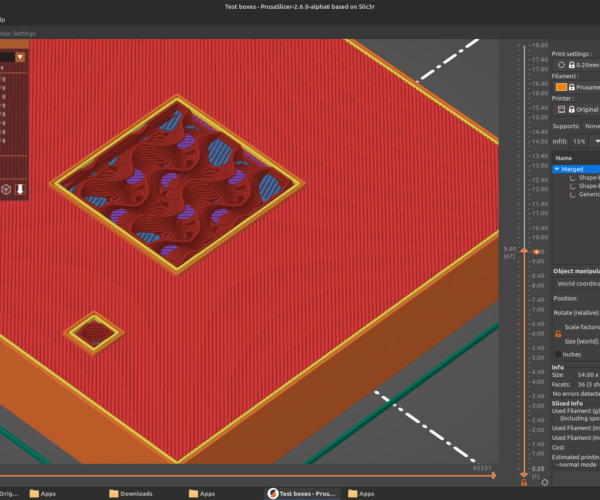

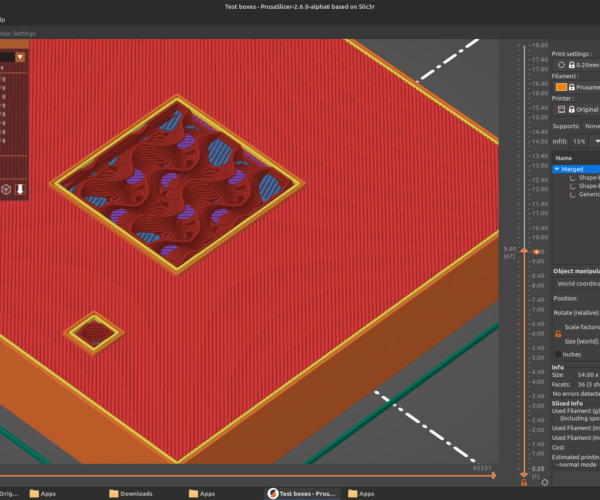

However, in 2.6.0 alpha 6, we see the behavior is a little different. Whereas in 2.5.2 the solid infill stuck under the edges of the upper boxes quite a distance, which meant the small box printed 100% on the top solid infill, here in 2.6.0 alpha 6 we see they don't bring the top solid infill into either box at all. This means even more continuously connected infill on the larger box, and what looks like it'll be a stronger connection on the smaller box.

Now, if we slice down a few more layers, to the first solid infill layer on the bridging infill layer, you can see the infill is not connected between the lower box and the smaller upper box, even though the infills are connected on the larger upper box and lower box. Instead though, it prints the bridging infill as one continuous layer below the smaller upper box. Likely because it stops bridging infill at infill, to anchor, and this is just too small. If they didn't run bridging infill, there wouldn't be bridging infill for the solid infill to sit on. But they only have this one layer, and then the solid infill is cut away and they start infilling infill for the small box. So by the time you reach the top solid infill layer of the lower platform box, the small upper box has multiple layers of infill already made and anchored to the walls of the solid infill below, which should hopefully make it stronger than just printing everything on top of the top solid infill layer.

RE: Avoiding solid topfill under pegs on a slab?

Try the 2.6 alpha release. In 2.5.2, I get this, which looks like what you have:

However, in 2.6.0 alpha 6, we see the behavior is a little different. Whereas in 2.5.2 the solid infill stuck under the edges of the upper boxes quite a distance, which meant the small box printed 100% on the top solid infill, here in 2.6.0 alpha 6 we see they don't bring the top solid infill into either box at all. This means even more continuously connected infill on the larger box, and what looks like it'll be a stronger connection on the smaller box.

Now, if we slice down a few more layers, to the first solid infill layer on the bridging infill layer, you can see the infill is not connected between the lower box and the smaller upper box, even though the infills are connected on the larger upper box and lower box. Instead though, it prints the bridging infill as one continuous layer below the smaller upper box. Likely because it stops bridging infill at infill, to anchor, and this is just too small. If they didn't run bridging infill, there wouldn't be bridging infill for the solid infill to sit on. But they only have this one layer, and then the solid infill is cut away and they start infilling infill for the small box. So by the time you reach the top solid infill layer of the lower platform box, the small upper box has multiple layers of infill already made and anchored to the walls of the solid infill below, which should hopefully make it stronger than just printing everything on top of the top solid infill layer.

RE: Avoiding solid topfill under pegs on a slab?

The behaviour in 2.6 is different yes. Its actually the cause of a couple of current Github bugs as its going too far in the opposite direction. The funny thing (relatively) is that there are open issues from people who WANT solid infill under their top features for stuff like text etc where strength isn't a factor, they want the nice neat solid topfill layer, while others want the larger gap with it only just under the perimeters on top for the strength. Devs get damned either way. This is why I would prefer it was a configurable value like you can get in SuSi.

Regardless, at the moment it is best to work around the slicer limitations. No matter the version used.

For one thing a sharp 90 degree transition like that is a stress riser. It concentrates the stresses into a smaller area making them more likely to break. Its why professional designers use chamfers and fillets on edges. Its not just for looks. It evens out stresses too.

Beyond that the standard solution to weaker geometry breaking off that those layers is to model in a small void into the part that goes through the boundary area. That way the slicer will surround the void with perimeters. By placing and sizing the shape and position of the void you can then control things much more precisely and get perimeters where YOU want them.

The same can be achieved with a modifier mesh in PS using a negative space. However placing small modifiers in precise locations in PS is difficult as they havent got any transparency or wireframe view tools. Its much easier to do in CAD.