RE: VFA Artifacts on X+Y Straight Edges

Does the pitch of the vertical lines change when you change the linear motion speed, in proportion with the speed? (That's what one would expect to see if it is a mechanical resonance at a fixed frequency, which gets spread out over more or less distance depending on the travel speed.)

Or is it a fixed pitch independent of the speed? That might indicate that it is related to some mechanical irrgeularity in the system which has that lateral pitch -- e.g. the tooth pitch of the belt. If it were indeed the belt teeth, I would expect the VFA pitch to be the exactly the same as the belt tooth pitch for walls oriented at +- 45°, where only one of the motors moves.

But then, for a +-45° movement with only one motor active, and at a constant speed without acceleration -- what would induce motions in the direction orthogonal to the travel direction, which become visible as VFAs? One could envision speed variations in the direction of travel if there are irregularities in the motor, idlers, belt... But it would take something else to induce motion in the orthogonal direction; or what am I missing?

RE: VFA Artifacts on X+Y Straight Edges

I posted an answer to this a few hours ago but I dont see it in this thread, so again:

If this still happens at 45° rotation on all wall sides, then I would not expect one of the motors to have an issue. I would have to be both motors with the same defect to still show up.

I rather think it is one of the idlers that are always rotating, which are the ones on the gantry (?). Mayber you can check those for eccentricity.

RE: VFA Artifacts on X+Y Straight Edges

This is very much like the same conversation in the XL forum

https://forum.prusa3d.com/forum/original-prusa-xl-tool-changer-hardware-firmware-and-software-help/ringing-ghosting-pattern-all-over-my-prints/

2022 - Creality Ender 3 V2

2024 - Prusa MK4S/MMU3

2026 - Bambu P2S/AMS2Pro

2028 - Liquid CMY for billions of colors?

RE: VFA Artifacts on X+Y Straight Edges

Can you try this? https://www.printables.com/model/1189256-vfa-test-prusa-core-one

Oops, I confused myself (again!) and stand corrected! I misspoke (again).

CoreXY only moves at exactly 45° when ONLY ONE BELT moves while the other belt is stationary. So @el_hopaness is right. A vertical surface printed at 45° would use only one belt, so VFAs should be reduced, especially in the direction that uses the non-bent pulley.

Sorry for the brain-fart!

Yes, it will show even at 45°, because one belt would be speeding up and slowing down with every revolution of the bent shaft while the other belt speed is constant. CoreXY only moves at exactly 45° when both belts move the same (or exact opposite) speeds.

RE:

This is very much like the same conversation in the XL forum

https://forum.prusa3d.com/forum/original-prusa-xl-tool-changer-hardware-firmware-and-software-help/ringing-ghosting-pattern-all-over-my-prints/

Thanks for the link. It's frustrating that the XL thread (and the second one linked from there) do not come to a clear resolution either. Phase stepping is apparently not the silver bullet for the cases discussed there, since it was already available and it's mentioned that the issue occurrs with phase stepping on or off.

The consensus seems to be that this must be related to the belt tooth pitch (2 mm), and could be due to the toothed side of the belt running over smooth idlers, or irregularities in the toothed pulleys on the motors, or skewed routing of the belts such that the teeth brush against the rims of the idlers. Replacing the smooth idler wheels with toothed idlers has reportedly reduced the VFAs for those who tried it, but has not removed them entirely.

It would be really helpful if Prusa support had some presence in this forum and would add updates with known problem resolutions. I can't understand why Prusa does not do that. It would probably reduce the overall support workload significantly if more people could find proven self-help solutions on the forum, rather than just watching other users going round in circles in long threads.

RE: VFA Artifacts on X+Y Straight Edges

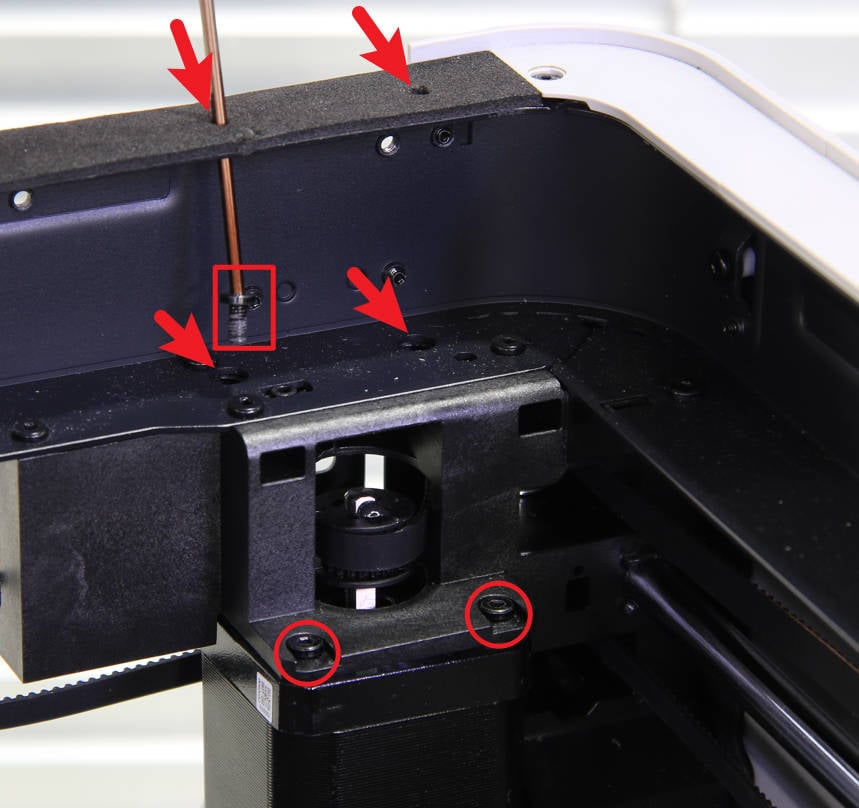

Interestingly, Bambu has chosen a different belt path for their printers. The toothed side of the belt is directed towards the motor pulleys, of course, but all the (smooth) idlers only see the smooth side of the belt. They have provided two extra idlers next to each motor, to form a U-shaped loop where the motor pulley can drive the belt. Not a great picture below, but it hopefully helps to understand what I mean.

Looks like Bambu were onto something which Prusa did not consider relevant. I don't trust Bambu's business model, but their engineering -- and specifically their design for manufacturing -- is really strong. Whatever the parts or assembly tolerance issue is that causes some Prusa CoreXY printers to have this VFA problem, I would not be surprised if Bambu had made their design immune to these tolerances (and can hence use cheaper parts).

RE: VFA Artifacts on X+Y Straight Edges

VFA seems to happen to Bambu printers as well - long posts about replacing idlers with toothed (mixed results) or covering idlers with teflon tape with better results.

https://forum.bambulab.com/t/persistent-2mm-vfas-on-x-axis/30883

I will try the specific VFA test when I can.

RE: VFA Artifacts on X+Y Straight Edges

Oh, right -- it looks like Bambu were not fully consistent with the "toothed belt side towards toothed gears, flat side towards flat idlers" concept. Where the belts make the turn from the Y rails towards the X gantry, the toothed side of the belt runs over smooth idlers. So there is a potential for VFAs at these four spots (still assuming that the VFAs are related to the teeth and their interaction with idlers or rims).

VFA seems to happen to Bambu printers as well - long posts about replacing idlers with toothed (mixed results) or covering idlers with teflon tape with better results.

https://forum.bambulab.com/t/persistent-2mm-vfas-on-x-axis/30883

I will try the specific VFA test when I can.

RE: VFA Artifacts on X+Y Straight Edges

One sometimes finds the advice that is makes a difference whether original Gates belts and toothed pulleys are used. Cheaper brands or no-name clones are said to be more prone to causing artefacts, due to their higher tolerances. See e.g. here: https://github.com/AndrewEllis93/Print-Tuning-Guide/blob/main/articles/troubleshooting/vfas.md

Does Prusa still use original Gates parts for the belts and for the toothed pulleys on the XY motors? Or did they switch to a different brand at some point, in response to competitive cost pressure?

RE: VFA Artifacts on X+Y Straight Edges

I will add my few cents to the problem. I have similar issue, and noise is also quite worse than described by other, probably correlated. I did the mentioned vfa test, and it seems that one stepper or idler is worse than one other side

RE: VFA Artifacts on X+Y Straight Edges

I'm back in discussions with support via email, printing yet more test boxes to demonstrate the problem. I've attached a picture of the prusa provided test gcode for me to print where the VFAs are very obvious.

The VFAs on the VFA tower print in this thread were very mild in comparison to the box prints i've been doing. Confusingly, you can see them on one side of the wall more prominently than the the other.

For the 90 degree print I see VFAs from the bottom up to about the halfway speed point where they fade out - they return again for the top speed quarter of the tower

For the 0 degree print I see VFAs in around the middle speeds and some in the higher speeds.

RE: VFA Artifacts on X+Y Straight Edges

There's a new video out from "3D Musketeers" on Youtube, www.youtube.com/watch?v=a3PvrFWEHBQ. It was shot during a visit to Prusa, and one of the presenters is a Prusa employee. Unsurprisingly, most of the time it feels like a Prusa promo video, with two guys discussing all the clever design decisions that were made. (All the ones which have been stressed before -- robust enclosure, build chamber cooling, door lock etc.).

But interestingly, around 6:00 Mikolas (the Prusa guy) mentions that they are still working on the acoustic resonances which do occur at certain speeds. So at least they are aware that it could do with some improvement! I was wondering whether the "working on it" refers to enabling a calibration for the phase stepping control? But that term is not mentioned.

BTW, at 18:00 they also explain that, by design, it's impossible to assemble the printer skewed. So rest assured that your unit can't be a dud if it prints with strong VFAs... 🙄

RE: VFA Artifacts on X+Y Straight Edges

Mine looks very similar to the last example by @baztm above. I checked the belt tuning and mine were at 94 and 97. I adjusted them down so they're now at 84/86 and no change to the VFAs. Very interested to see what comes of this.

One related note: my QIDI Q1 Pro has this issue. My Voron 0.2 does not, which uses (I think) the same Gates belts but specs call for toothed idlers where the belt teeth face the pulley. Confusing decision.

RE: VFA Artifacts on X+Y Straight Edges

I haven't heard anything from support in a few days again, after an initially positive response from them. I'm a bit disheartened. I'd rather not immediately start guessing and swapping pulleys on a brand new printer to fix this but basically anything that has a straight edge at the moment comes out awfully as shown in the boxes.

I've noticed when manually moving the gantry that there are positions where the ganty moves with a bit more resistance and causes the head to move a bit to the left or right. Almost like a flat spot on a pulley or something. No idea how to take it apart yet but as stated, would rather not considering it's a week old!

Pretty keen to send it back if support don't have much of a solution as my MK4S was far better than this.

RE: VFA Artifacts on X+Y Straight Edges

Does the Core one have the toothed portion of the belt running over a smooth pulley like the XL?

RE: VFA Artifacts on X+Y Straight Edges

Does the Core one have the toothed portion of the belt running over a smooth pulley like the XL?

It sure does, as discussed above.

RE: VFA Artifacts on X+Y Straight Edges

Does the Core one have the toothed portion of the belt running over a smooth pulley like the XL?

It sure does, as discussed above.

Thanks. I see it pointed out for the XL, but I don't see where anyone specifically said the Core One is the same way.

I'm currently in the process of changing the smooth idler to a toothed version on my XL. I printed a test part before the change and plan to print it again after. The VFA's are not bad on my machine, but we'll see if it makes an improvement. I got genuine gates toothed idlers which are 1mm thicker than the stock smooth idler, and therefore I had to modify make the opening for the pulley bigger. At the same time I'm also replacing all of the core xy parts with PCCF, so it may be a week or so before I have results.

RE: VFA Artifacts on X+Y Straight Edges

I also taked to the prusa support because of the idlers. I have my XL since about 1,5 years and a few idlers already squeaking.

The support offered to send me a new complete set of pulleys. But since I still have other problems with my Prusa, it was better to send my XL in for repair.

I also asked the support which manufacturer the pulleys they use are from. They produce them themselves in-house.

Here is the PDF that the support gave me in the attachment.

My XL story: https://investegate.de/en/prusa-xl-complaint-review/

RE: VFA Artifacts on X+Y Straight Edges

Here's a picture of the one I ordered. The thickness is 10 vs. 9 on the Prusa pulley. That's the reason I had to alter the parts where it mounts by increasing the width by .5mm per side. All of the rest of the critical dimensions are good. The od of the pulley is smaller, but the area where the belt rides is super close.

Well see if it makes any difference.

I'm kind of surprised that they run the toothed part of the belt on the smooth pulley, but it seems like common practice on 3d printers. It's that way on my Prusa i3 style machines, and doesn't seem to cause a problem, however the belts do a 180° wrap vs. a 90° wrap, and the belts are much shorter. So I'm not sure how that affects the end result. I'm a mechanical engineer and I can say that from a design perspective it's not something that I'd do, but usually everything on a machine is a particular way for a reason. Since I don't know the reason they used a smooth pulley in that location I can't really knock it, but I'll try this to see if it makes any difference.

RE: VFA Artifacts on X+Y Straight Edges

Changed filament for now but I've noticed some faces on the cube seem to have them reduced compared to others.

X(1) and Y2 have very similar artifacting but the parallel faces show reduced artifacting, with X2 probably the best. (Ignore the gyroid infil wave showing through)

Not sure what this means. I also noticed that the right belt (from the perspective of looking at the printer through the door...) is much much noiser if I move it by hand compared to the left belt. I wonder if the right motor is cooked?