RE: Nozzle cleaning consistently fails with PETG

Thank you for updating. I thought that this would be the issue in my case, but unfortunately, the cleaning problem occurred on every bed finish(smooth and satin) with every material(pla,pet-g, ASA, PC,tpu). It is so annoying that sometimes it takes 3-4 tries and up to 20 minutes to complete, so if I need to print something quickly, I just use another printer.

RE: Nozzle cleaning consistently fails with PETG

You're missing the point. My nozzle was perfectly clean when it failed. It's not that you have to clean it with a wire brush, the problem is that something is wrong with how it works now, and it should be repaired with the next Firmware update. I repeat, it only happens with a textured plate.

Apologies, my post was aimed at the members who expressed that cleaning the nozzle with a brush was perfectly acceptable.

Not the issue here, but if you think you'll never need to clean your nozzle then you'll eventually have problems. No automated process is going to clean the buildup off of your nozzle, especially when printing PETG, PCCF, ASA etc. If you print exclusively PLA, then maybe, but it will still build up over time around the nozzle and tip.

It's a good idea to check your nozzle before starting your print.

RE: Nozzle cleaning consistently fails with PETG

You're missing the point. My nozzle was perfectly clean when it failed. It's not that you have to clean it with a wire brush, the problem is that something is wrong with how it works now, and it should be repaired with the next Firmware update. I repeat, it only happens with a textured plate.

Apologies, my post was aimed at the members who expressed that cleaning the nozzle with a brush was perfectly acceptable.

Not the issue here, but if you think you'll never need to clean your nozzle then you'll eventually have problems. No automated process is going to clean the buildup off of your nozzle, especially when printing PETG, PCCF, ASA etc. If you print exclusively PLA, then maybe, but it will still build up over time around the nozzle and tip.

It's a good idea to check your nozzle before starting your print.

I'm under no illusion that the nozzle will not need cleaning intermittently, that makes perfect sense. What doesn't, is that a member alluded to the fact that cleaning the nozzle would stop the nozzle clean error reported by a few other members to get the printer to start. Drying filament was mentioned, but was then eliminated in a rebuttal from others. I believe the issue is that oozing was not cleaned from the nozzle before bed levelling causing an error that delayed prints. Having to use a brush to clean the nozzle before a print has started, when the nozzle should be cleaned during the automated startup process was where I was aiming my comment. Please accept my apologies if I have the wrong end of the 3D printed stick, but that's what I was taking from it.

Scott

RE: Nozzle cleaning consistently fails with PETG

Hey dude. Just coz I said it worked doesn’t mean I find it acceptable. But a workaround is a workaround right…?

RE: Nozzle cleaning consistently fails with PETG

After a week of experimenting, here is the workaround that works for me. The problem is filament leaking from the nozzle when nozzle cleaning is in progress and of course during probing routine. To prevent this I just load filament, set nozzle temperature aprox 10°C higher then print temperature of respective material and let the printer 5-10mins at rest. This allows all the content from inside of the nozzle to drain. I just remove the leaked piece hanging from the nozzle (often just drop down itself) and start the print. Nozzle cleaning routine then passes without any problem as well as probing routine which in this case doesn’t leave dots of filament on the sheet. I know, it’s not perfect, but it saves my nerves until Prusa solve this in firmware. Happy printing!

RE: Nozzle cleaning consistently fails with PETG

Put some glue on the nozzle cleaning area, start printing. Works reliable all the time!

The issue is probably under the nozzle cleaning area of the print sheet is no heat bed. The temperature of the print sheet on that position is probably to low!

RE:

I hope they fix it soon, it's been driving me mad the last two days. Textured sheet that's a lot more flexible than the supplied smooth sheet. I wonder if this could be the issue as it is probing right out to the unsupported corner of the sheet.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Nozzle cleaning consistently fails with PETG

I hope they fix it soon, it's been driving me mad the last two days. Textured sheet that's a lot more flexible than the supplied smooth sheet. I wonder if this could be the issue as it is probing right out to the unsupported corner of the sheet.

I struggled with the same issue and the problem is gone now … not a single failure anymore!

What did I do?

I checked the flatness of the print sheet for deviation in Z. Found out that when measuring in the back (the single Z stepper) vs. the two front corners there was a difference of 0,3mm.

So here’s the fix:

1. move the Z axis in the manual menu to zero (all the way up)

2. switch off the motors

3. using your fingers turn all three spindles so that the nozzle tip touches the print sheet in all three corners

4. switch on the motors again

5. re-check

For me it worked perfectly fine, didn’t have a single nozzle cleaning failure in about a week of intensive printing - no matter what sheet or filament type.

happy printing!

Mathias

RE: Nozzle cleaning consistently fails with PETG

That works fine, but you lose it the next time the printer recalibrates the Z-axis. I expect someone will come up with a mod to place an adjustable stop at the bottom of each Z rod.

1. move the Z axis in the manual menu to zero (all the way up)

2. switch off the motors

3. using your fingers turn all three spindles so that the nozzle tip touches the print sheet in all three corners

4. switch on the motors again

5. re-check

For me it worked perfectly fine, didn’t have a single nozzle cleaning failure in about a week of intensive printing - no matter what sheet or filament type.

happy printing!

Mathias

2022 - Creality Ender 3 V2

2024 - Prusa MK4S/MMU3

2026 - Bambu P2S/AMS2Pro

2028 - Liquid CMY for billions of colors?

RE: Nozzle cleaning consistently fails with PETG

Didn’t observe that! I think once it is aligned the way I did it it stays correctly calibrated in "z“. At least I measured no change in deviation after z calibration.

Anyway, Prusa should bring the new firmware to life since this is not the only issue. Also found a bug in the slicer software when using the entire buildplate.

happy printing!

That works fine, but you lose it the next time the printer recalibrates the Z-axis. I expect someone will come up with a mod to place an adjustable stop at the bottom of each Z rod.

1. move the Z axis in the manual menu to zero (all the way up)

2. switch off the motors

3. using your fingers turn all three spindles so that the nozzle tip touches the print sheet in all three corners

4. switch on the motors again

5. re-check

For me it worked perfectly fine, didn’t have a single nozzle cleaning failure in about a week of intensive printing - no matter what sheet or filament type.

happy printing!

Mathias

RE: Nozzle cleaning consistently fails with PETG

Didn’t observe that! I think once it is aligned the way I did it it stays correctly calibrated in "z“. At least I measured no change in deviation after z calibration.

I would expect the adjustment to be lost after Z homing. Not sure how often that needs to happen though?

RE: Nozzle cleaning consistently fails with PETG

I was gonna say "I wonder why it needs to heat up the nozzle during bed leveling anyway (because it can cause oozing which leaves small filament marks all of the print sheet)" but then I realized that it needs to heat up the nozzle so it can thermally expand to its printing size and thus give a more accurate z-measurement. ... Or at least that's what I think. Hopefully there's a good reason as to why I've cleaned off small specs of TPU from the bed leveling process the last 20 prints.

RE: Nozzle cleaning consistently fails with PETG

Haven't had my Core 1 long, but it appears it homes to the nozzle prior to the start of the print so z-motors are not bottoming out on anything.

Didn’t observe that! I think once it is aligned the way I did it it stays correctly calibrated in "z“. At least I measured no change in deviation after z calibration.

I would expect the adjustment to be lost after Z homing. Not sure how often that needs to happen though?

RE: Nozzle cleaning consistently fails with PETG

I already found the bed levelling after Z axis homing wasn't the best and relevelled my bed using a business card and the turn each screw by hand with motors disabled method until each point nearby the screws was the same gap (Same level of drag on card).

I just redid it but this time with the bed at PETG printing temperature 85Deg C and there was a little variance compared to cold.

Anyway, the upshot of it is that where yesterday I could hardly get the printer to print anything in PETG, it has now just done its third successful print without failing a nozzle clean.

So definitely give this a go and see if it helps and report back please.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Nozzle cleaning consistently fails with PETG

10 prints later and not one failed nozzle clean.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Nozzle cleaning consistently fails with PETG

Strill waiting for the firmware update (or filament profile update if that does the trick). The higher the temp of the filament and the more CF the worse. And I don't do PLA/PETG at all, so PITA

I made a few test prints with PLA and they came off fine, however, when I switched to PETG for some structural parts I was getting constant nozzle cleaning errors when the print started.

These errors were on the textured sheet (which doesn't 'grip' the filament off the nozzle as well as the smooth ones during cleaning) and a small 'pancake' of filament would just stick to the tip of the nozzle during this process and it would fail. Even if I tried my best to clean the nozzle it still failed.

I finally managed to get a PETG print to start after making sure the inserted filament had stopped oozing and cleaning it thoroughly, but the next print I had the same issue. I'd have to babysit the printer to make sure not a single bit of filament was on the nozzle during the cleaning or it would fail.

My other printer is a MK4s with MMU3, which I never had issues with because the filament is only loaded when the print actually starts, so this may be an issue with the MK4s too, but this is the first time I'm experiencing this issue and its with the Core One.

I face the same problem and already contacted support 3 times! Even when the nozzle is perfectly clean it fails (also with PETG). Don’t know if the temperature for cleaning at 170 degrees is correct either. Support told me that they are aware of the problem with the Core One and a new firmware release should fix it … it’s scheduled for next week. We’ll see…

Also I found out the the bed ist tilt by about 0,1 to 0,2 mm from behind - e.g. the front of the printplate ist lower compared to the back. Maybe this also contributes to the problem. Prusa is really pushing out new Core Ones and I can imagine that assembly is not done perfectly! One example is the front door handle which is not securely in place.

I hope they hurry up fixing the firmware since I encountered some other flaws !!!

RE: Nozzle cleaning consistently fails with PETG

oh, btw. Might be coincidents, but maybe someone makes sense out of it: If I run the printer all day through the later the day the less often I observe the issue. Just a feeling and for sure I am not going to test this out

RE: Nozzle cleaning consistently fails with PETG

Hi there,

I also faced this issue a lot. Almost every print needed babysitting to pass the nozzle cleaning step, even though it was shining clean as brand new...

I made several assumptions, especially like some other found here that using an old MK4S satin sheet for instance may lead to inconsistent measurement because of the marking. But even when I pull down the plate off of 20mm in Y, I had a lot of failure. I also attempted a manual calibration using the good old business card grabbing technique. I may have found it was possibly better with PLA without certainty, but I still had failures with PETG, ASA, PC-ABS and most of all, even without any filament loaded...

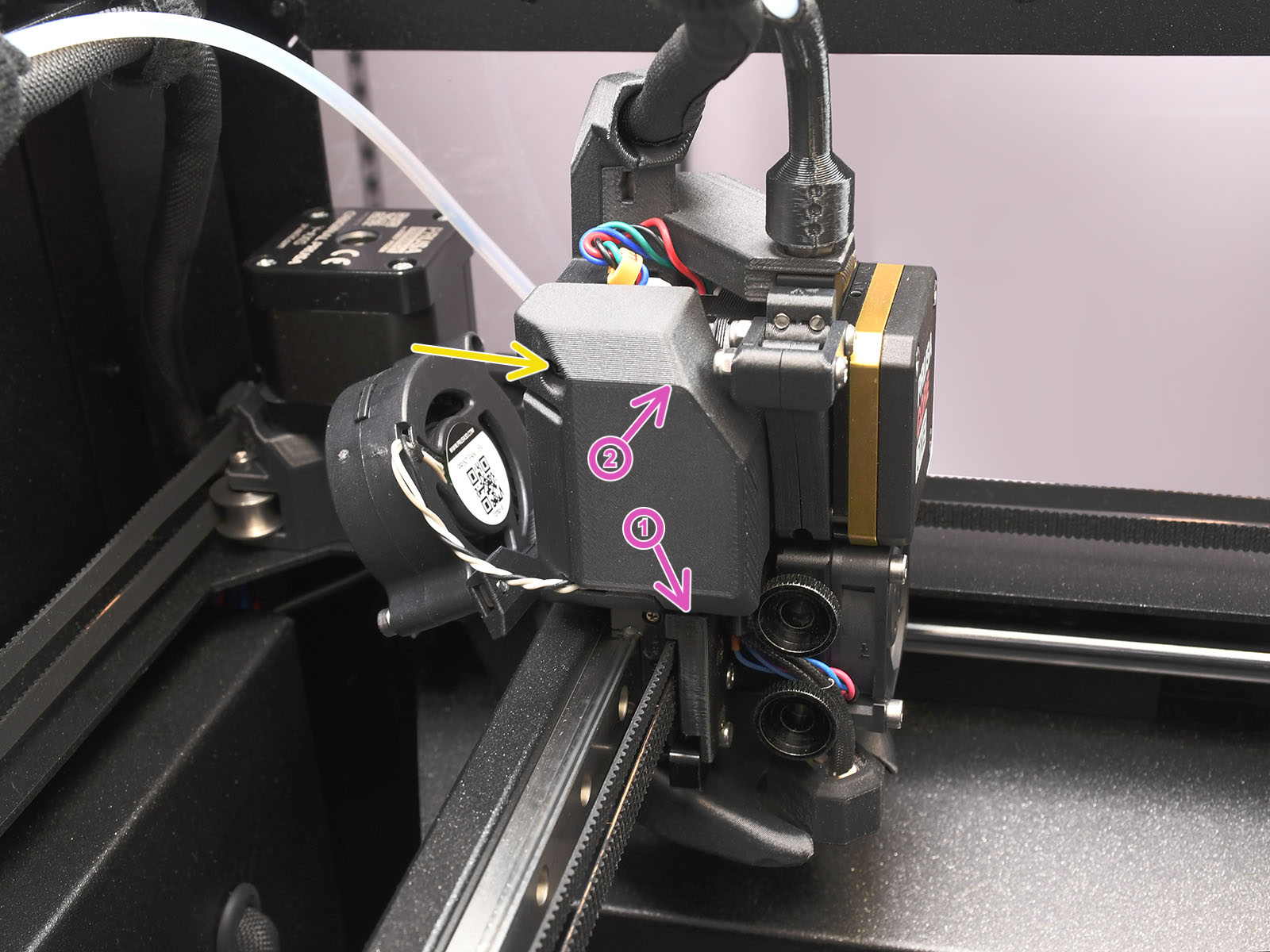

Then I took the time to look at this CORE One and using the Sensor Info menu to look at the loadcell value, I almost immediately understood what was going on. The loadcell is over-constrained by the pneufit mount plus the cable bundle relief. I first unmounted the pneufit but it wasn't enough, very visible on the value of the loadcell. Then I released a bit the two screws of the mount/cover at the back of the nextruder and... 100% success on 12 attempts in a row mixing PETG and PC-ABS!

Try by yourself, touching "normally" the nozzle produce a variation of ~300 of the sensor value, but a slight touch on the cable bundle can produce hundred to thousand points of delta, and the value may even not go back to ~0.

Next step when I'll find time is to take down the nextruder assembly and re-mount it appropriately, if possible, hoping the defect keep away from my printer.

RE: Nozzle cleaning consistently fails with PETG

The loadcell is over-constrained by the pneufit mount plus the cable bundle relief. I first unmounted the pneufit but it wasn't enough, very visible on the value of the loadcell. Then I released a bit the two screws of the mount/cover at the back of the nextruder and... 100% success on 12 attempts in a row mixing PETG and PC-ABS!

This sounds like a very plausible class of explanation, thank you! But I am unsure about the exact over-constraint you are describing. It would probably be clear if I had a Core One Nextruder in front of me, but since I'm still waiting for my kit to arrive... could you please elaborate?

I assume the constraints are from the PTFE tube connector and the angled cable guide on top of the Nextruder? Where exactly is the loadcell sensor mounted to make it sensitive to strains from those two components? Or did I misunderstand?

RE: Nozzle cleaning consistently fails with PETG

Let me the time to confirm my results before declaring victory. 😀

The loadcell is... the whole complex aluminum part of the Nextruder. It is sensitive enough to detect a finger press anywhere on the printhead (without locating it of course).

If you look at the picture below, you can see the big mount just above the idler, going up to the strain relief at the back. It is hold by the pneufit itself (encapsulated into the plastic part), directly screwed into the aluminium body of the loadcell.

I hope to be right, and I hope this could be confirmed by someone else in the meanwhile.