Belt tensioner screw seized after 1 day of use

Hey everyone,

I wanted to share a small (and slightly frustrating) experience with my new Core One, in case it helps others or Prusa can take note for future batches.

After just one day of use, I noticed that the belt tension on one axis was too high (firmware 6.4) , so I decided to adjust it. Unfortunately, the tensioner screw was extremely hard to loosen — I quickly realized that the problem was a seized screw, and the square nut inside the pulley was turning along with it.

I contacted the Prusa Chat support, and they confirmed my suspicion. By the way, the support team was super helpful and nice, really appreciated that.

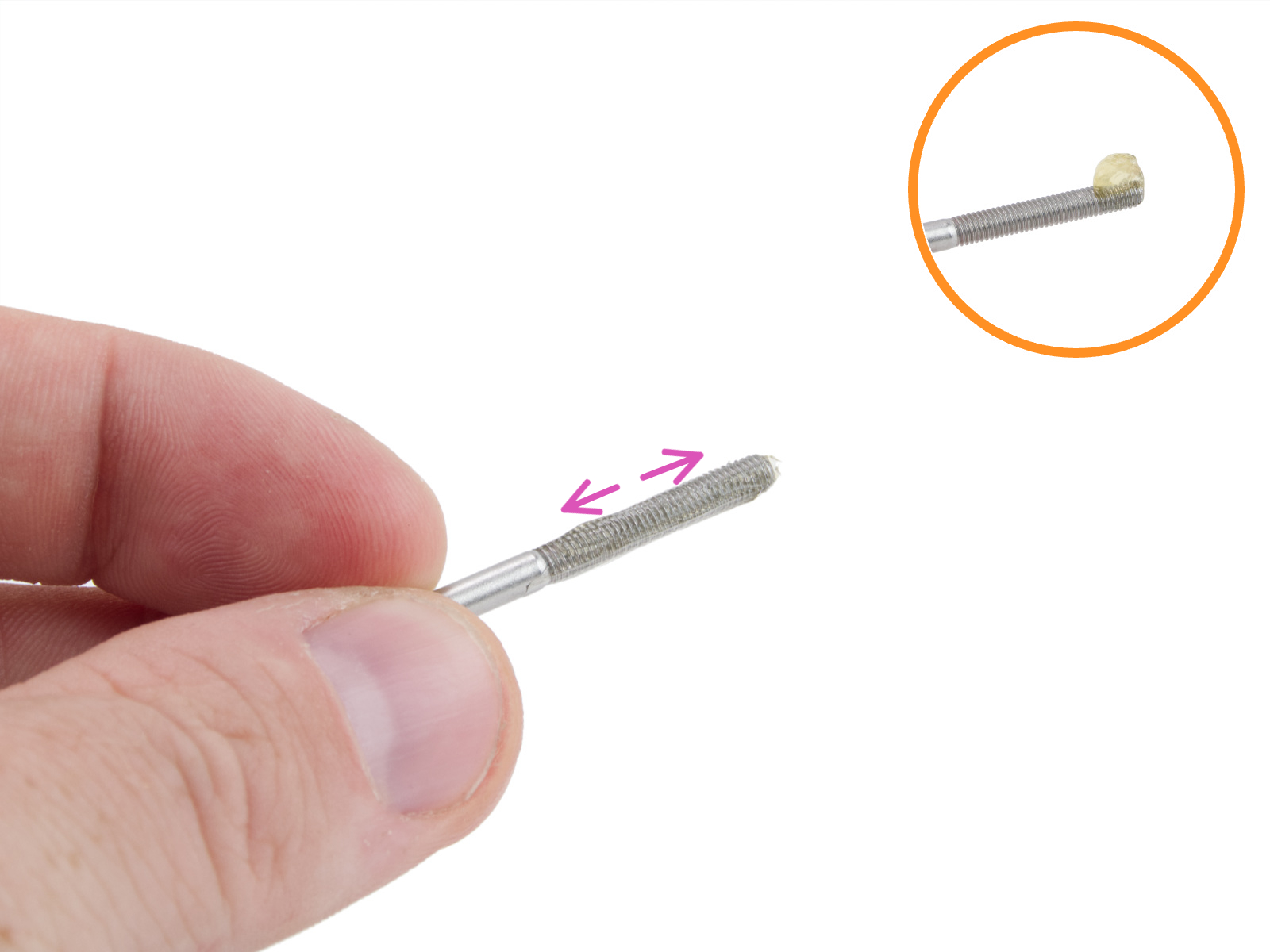

So I ordered a replacement tensioner part from Prusa, but in the meantime, I tried to disassemble the damaged one following the online guide. Sadly, I had to destroy the pulley support and eventually cut the screw to remove it, since the screw and nut were completely bonded together (see photos).

Because I didn’t have spare screws or nuts on hand, I ordered some locally as well. I still wanted to test, so I reprinted the pulley support in PETG on my Mini+ while waiting for the official PCCF replacement part to arrive.

I’ve seen a few others mentioning similar issues, so I mostly wanted to share this as a heads-up — and to ask if there’s any advice to prevent this in the future, since it’s not ideal to run into a mechanical issue like that just one day after purchase.

In addition to applying some grease on the screw, is there anything else you’d recommend to avoid this kind of problem?

RE:

Did you build the printer yourself or did you buy it pre-assembled?

This was a well known issue mainly for the earlier printers, and its caused by metal-on-metal contact between the screw and the nut, where they somehow bind together. To prevent this from happening again, simply add a small amount of lubricant onto the screw before inserting. I thought this issue had been completely resolved by now, both for pre-assembled mchines and kits. But apparently thats not the case?

Ive added the lube and its been perfectly fine ever since, but there is also an alternative mode someone made, where the quare nut is replace with a threaded insert:

https://www.printables.com/model/1360563-core-one-belt-tensioner-pulley-to-take-a-threaded

RE: Belt tensioner screw seized after 1 day of use

I thought this issue had been completely resolved by now, both for pre-assembled machines and kits. But apparently thats not the case?

How would it have been resolved by Prusa? Were there any engineering changes? The community-developed replacement tensioners with brass insert are the only remedy I am aware of, but I don't think Prusa has adopted these.

RE: Belt tensioner screw seized after 1 day of use

Hi, thanks for your reply!

This is a pre-assembled unit.

I saw the version with an insert, but I don’t have any on hand and I’ve never used one before — total newbie here . I managed to find a screw and a nut, tested it with a PETG replacement part after lubricating the screw — works like a charm, with the right belt tension.

I’ll run a few small prints over the next days and install some upgrades I printed on my Mini+ (like the automatic chamber vent). Hopefully, I’ll receive the PCCF replacement part next week.

RE: Belt tensioner screw seized after 1 day of use

I think you will be alright with the lubricated screw. Switching to the brass insert is more a case of "this is the way to do it properly" than an absolute necessity: The brass/steel material combination is not prone to "galling" (seizing) like the stock materials, and the longer thread of the brass insert will better resist the tilting force of the belt tension.

RE: Belt tensioner screw seized after 1 day of use

I'd assume all screws on pre-assembled units would be lubed at the factory, the manual for the kit now has an additional step to lube the screw. I would call that "resolved".

RE: Belt tensioner screw seized after 1 day of use

I'd assume all screws on pre-assembled units would be lubed at the factory, the manual for the kit now has an additional step to lube the screw. I would call that "resolved".

I lubricated the screw like that, but the screw that came with the printer was completely dry — looks like this one missed the grease at the factory.

RE: Belt tensioner screw seized after 1 day of use

I don't know what metal is used for these screws, since I did not buy the kit; But I have seen stainless steel nuts and bolts "Gall" (Seized, literally weld together) even after being hand tightened. It was amazing to see. And these were larger bolts, like used on huge radio antennas. At the end of the day, we hand tightened them to test fit. The next day, when trying to remove them, they were stuck hard. Applying a socket wrench to try and loosen, simply sheered the bolt head off. Amazing. So for the last 10 years, anytime we use stainless steel, we apply a small amount of anti-lock compound (a lubricant). Can this happen with other metals?

Neal

RE:

The galling and freezing you describe is not uncommon with stainless steel threaded fasteners. It happened to me with the belt tensioning screw in my kit Mk 4. Fortunately, I was able to expose enough of the M3 cap screw that I could cut it with a fine jeweler’s saw without damaging the printed plastic part.

The solution is to completely discard the frozen fasteners, even if you can eventually get them apart with brute force. Then lubricate the new screw and nut with grease or an anti-seize paste. You can also consider replacing the fasteners with ones of two different metals. For example, a stainless steel screw and a brass nut or brass threaded insert. Brass in this situation is “self-lubricating.” If you decide to replace both fasteners with stainless steel, make sure you lubricate them first, then turn the threads together slowly to avoid any frictional heat.

RE: Belt tensioner screw seized after 1 day of use

You may also look in printables for a version of the tensioners with an embedded screw holder. Much better than the plastic only version.

RE: Belt tensioner screw seized after 1 day of use

I received the new belt tensioner pulley and everything is perfect now. I managed to set the belt tensions to 96/92 Hz, the gantry is square, and both input shaper and phase stepping are done.

I also ran a Vernier Skew Test and everything looks good, really happy with the results!