RE:

That sounds good to me. Have you ever thought about a second fan that brings air into the case from the outside? That's what you do with a PC case. Maybe you can increase the volume that way?

As I indicated, it is working well for me the way it is now -- at least during printing -- so I don't need any additional flow at the moment. And I don't want a huge inflow from one location (like an intake fan) as it seems that could act as a draft and cause warping. The current "little holes and gaps all over" does a good job of letting a little air in everywhere, without any big volume from any one place hitting the print.

Once the print is complete, my script pushes the fan to 100% -- and more intake would be nice then to cool everything down faster. I can certainly walk over and open a door at that point, but prefer an automated solution. 🙂 Another fan on a relay could work, but I think (at least with the power of the fan I'm using) just a few more inlet holes would do the job. Have to think about where to place those and how big they would need to be. It is all about finding right balance where temperature is controlled, but without causing drafts that are counterproductive to the entire purpose of having an enclosure.

RE: Enclosure and ASA, temp at 50C+

Isn't it from a warping perspective recommended that you have an even decrease of temperature all across the part during cooling? Ie a slowly cooling out enclosure? If you blow in a lot of cool air, you won't get that, even if no draft is hitting the part directly. I don't know how much difference it really makes though but it must create a lot of uneven tensions if thin segments cool much faster than thick ones.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Enclosure and ASA, temp at 50C+

Isn't it from a warping perspective recommended that you have an even decrease of temperature all across the part during cooling? Ie a slowly cooling out enclosure? If you blow in a lot of cool air, you won't get that, even if no draft is hitting the part directly. I don't know how much difference it really makes though but it must create a lot of uneven tensions if thin segments cool much faster than thick ones.

Agreed. That's why I lean towards (if anything at all) a few more small-ish intake holes, distributed around the enclosure, rather than an intake fan that would bring in a large volume at from one location. Same problem exists with what I said earlier about "opening a door", as it can lead to cooling too fast, as well as an uneven flow that cools some areas faster than others -- which is a recipe for warping on large or complex parts.

So, I think you are correct that a slow, passive cooldown would be the "safest" as regards any part stress, particularly for large parts. Not as important for small parts. I guess I am hoping a middle ground exists where I can cool things down a little faster after the print completes but not so fast (or unevenly) that it causes stress problems during the cooldown. What I am doing now (100% exhaust fan, but no additional intake) may be as close as I can get.

RE: Enclosure and ASA, temp at 50C+

But if I want to print PLA, with closed case. the cooling should be much better to get below 35 degrees to avoid heatcreep in the hotend. Constantly opening the lid and opening the doors is annoying in the long run. For me, it is so that even with the lid open, the temperature in the housing rises to 35 ° + even if I print PLA. As for printing ASA/ABS, I agree with you that too much or too strong cooling is counterproductive.

RE:

Printing PLA with doors closed is imho not recommended, because it could cause heat-creep inside the extruder and the filament getting too warm and soft for the gears. I use a spacer that keeps the doors about 10 cm apart. There is a model in enclosure related stuff.

RE: Enclosure and ASA, temp at 50C+

But if I want to print PLA, with closed case. the cooling should be much better to get below 35 degrees to avoid heatcreep in the hotend. Constantly opening the lid and opening the doors is annoying in the long run. For me, it is so that even with the lid open, the temperature in the housing rises to 35 ° + even if I print PLA. As for printing ASA/ABS, I agree with you that too much or too strong cooling is counterproductive.

True, PLA is a different story. I often forget about that because I almost never print it. I know Prusa says to just leave the doors open for PLA, though I hate having "manual steps" to remember when starting a print.

I do print a lot of PETG, and for that I have my script set for 30C enclosure temp. The single exhaust with no additional intake works fine for that, too. Of course, I still have that 21C room air, and there is less heat being produced with bed at 85-90C.

RE: Enclosure and ASA, temp at 50C+

Thats the reason because I want better cooling. 😉

Printing PLA with doors closed is imho not recommended, because it could cause heat-creep inside the extruder and the filament getting too warm and soft for the gears. I use a spacer that keeps the doors about 10 cm apart. There is a model in enclosure related stuff.

RE: Enclosure and ASA, temp at 50C+

I do print a lot of PETG, and for that I have my script set for 30C enclosure temp.

Correction -- I am using 35C target in the script for PETG.

RE: Enclosure and ASA, temp at 50C+

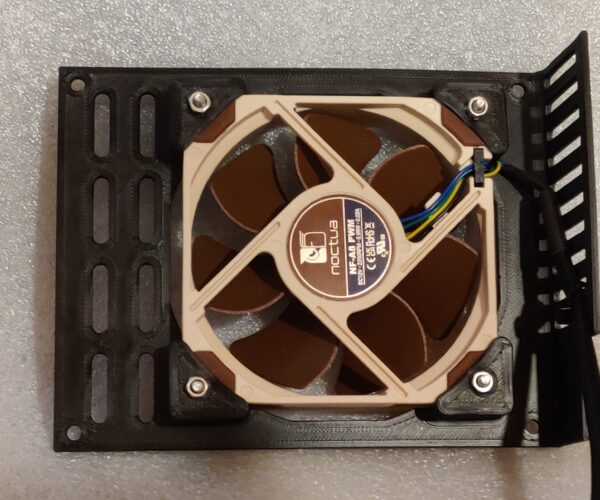

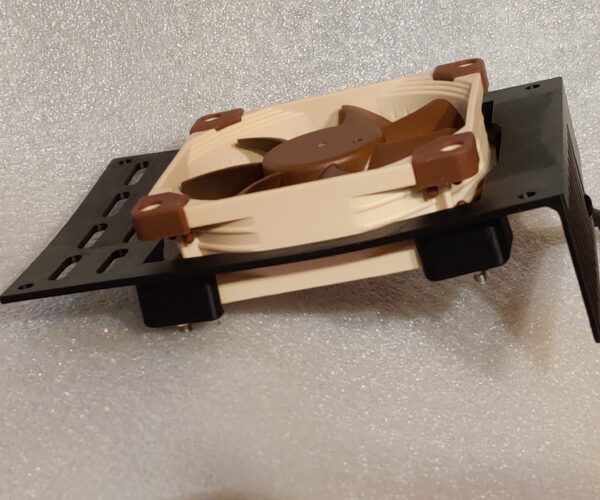

Here is the mount for an 80 mm Noctua fan on the electronics box that I have been testing for a few days. The clearance is enough for the x-axis motor to move. Tomorrow I want to remove the heat pads behind the xBuddy board, put a sheet of cork there and then I will see if that helps with the board temperature.

RE: Enclosure and ASA, temp at 50C+

I'm printing PETG right now and I'm at 35 degrees after about 30min. If I leave the lid open, it takes about 45-60 minutes to reach 35 degrees. My room temperature is currently at 24.6 degrees. Eventually I will also order a fan with temperature-dependent control.

I do print a lot of PETG, and for that I have my script set for 30C enclosure temp.

Correction -- I am using 35C target in the script for PETG.

RE: Enclosure and ASA, temp at 50C+

I think that with the cork, not such a good idea. This will act more as an insulator. Where should the heat then be dissipated? but try it out with pleasure and keep us up to date what has come out ok? I am curious.

Here is the mount for an 80 mm Noctua fan on the electronics box that I have been testing for a few days. The clearance is enough for the x-axis motor to move. Tomorrow I want to remove the heat pads behind the xBuddy board, put a sheet of cork there and then I will see if that helps with the board temperature.

RE:

I want to keep the heat from the heated bed from being transmitted to the board. The heat pads work in the wrong direction at high temperatures of the heated bed.

RE: Enclosure and ASA, temp at 50C+

To clarify: If you watch the board temp under Info > Sensor Info you can see that the board temperature quickly rises as soon as the heated bed is heating up. I am sure that is not because of processing operations in the board.

RE: Enclosure and ASA, temp at 50C+

I know what you mean but I don't think it's unusual. If you wait a while with PETG with 90 degrees heating bed temperature, the temperature of the board also rises to about 65 degrees. Then when I have 110 degree bed temp, it's not unusual for the board temp to go up to 69-70 degrees. I had a longer ASA pressure and the board temperature stabilized at just under 70 degrees for me, which I think is completely normal. and should not be a problem for the board. Also, I'm pretty sure the board has thermal protection and shuts down when it overheats.

RE: Enclosure and ASA, temp at 50C+

Yes, I had that happen many times when the ambient temperature in the room was over 40 °C. Then the printer had a red error screen with "freertos - configASSERT" and a wasted print. Which is what I am trying to remedy ...

Keeping the board temperature as low as possible cannot be a bad thing in general.

RE: Enclosure and ASA, temp at 50C+

Not processing like a CPU, but the board has power transistors that switch on and off to maintain the temp. This causes a lot of heat, and is almost certainly one of the three heatsinked items on the board.

As I stated earlier, printing PLA my board temp was like 55 °C, printing outside of an enclosure in 70 °F ambient temps. The heat was NOT coming from the bed, because holding my hand by the buddy box near the bed I could barely feel any warmth, but touching the buddy box it was hot. This indicates the vast majority of the heat is coming from the buddy board, not being transferred from the hot bed to the buddy board case.

To clarify: If you watch the board temp under Info > Sensor Info you can see that the board temperature quickly rises as soon as the heated bed is heating up. I am sure that is not because of processing operations in the board.

RE:

What do you think will happen when the heat bed behind the electronics case is hotter than the board? Will the lesser heat from the board flow into the back of the case or will the direction be reversed and the board will be heated instead of cooled? I have not heard of diode heat transfer pads yet ... 🙂

I never had problems with PLA, I made my observations with PETG/ASA temps.

RE:

What do you think will happen when the heat bed behind the electronics case is hotter than the board? Will the lesser heat from the board flow into the back of the case or will the direction be reversed and the board will be heated instead of cooled? I have not heard of diode heat transfer pads yet ... 🙂

I never had problems with PLA, I made my observations with PETG/ASA temps.

If the "freertos configAssert" red screen error you are getting is caused by electronics overheat, and if it stems from a design issue (i.e., electronics case heatsinking design and proximity to bed), then I'm wondering why there are so few reports of it here on the forums. I've seen only you and one other mk4 owner report it (so far). I know the forum doesn't represent a random sample or the majority of owners, but if anything, the participation is usually tilted towards those who experience problems. Maybe there are some more reports somewhere I have not seen.

Could it just be a problem with your particular board? Would it be worthwhile to contact Prusa support, and get a replacement BuddyBoard to try?

RE: Enclosure and ASA, temp at 50C+

Again, put a thermometer near the xBuddy case while printing. My money is it will not be hotter than the xBuddy case, in which case there will not be reverse heat flow.

What do you think will happen when the heat bed behind the electronics case is hotter than the board? Will the lesser heat from the board flow into the back of the case or will the direction be reversed and the board will be heated instead of cooled? I have not heard of diode heat transfer pads yet ... 🙂

I never had problems with PLA, I made my observations with PETG/ASA temps.

RE: Enclosure and ASA, temp at 50C+

I have reported it to email support on May 27. When I described that I was using OctoPrint, they just gave me the general answer "we do not support OctoPrint, print from USB stick." Not one word about the error screen or what could be the cause of it from them. This went over several emails back and forth. And the error is not restricted to printing with OctoPrint, it also happened when printing from USB stick. The error happened also frequently when the ambient temperature in the room with the printer and the enclosure was above 40 °C (that's 104 °F), on at least one day the ambient temp was 45 °C (113 °F). At lower ambient temp the error has not occurred as far as I remember. I doubt many here have used their printer under the same conditions. So I began my tests with the fan on the case which seems to help with the problem so far. The only way to be sure would be to video or timelapse the display during a print to get the temp value immediately before the red screen. But sometimes it happened after one hour, sometimes it happened 10 hours into a print job and I feel I have wasted enough time and filament on this and the correllation between the error and the board temperature is clear to me [points to large stack of failed prints]. So I want to change the setup to see if this can make it better. If you have a room that never goes above 25 °C (77 °F) you probably do not have to worry about it.