Dislodge and Z-motor issues

I have seen some recent dislodging issues so I thought I would share my experience here. I ordered the Mini+ Kit and assembled it and carefully followed the instructions (I have experience in assembling small scale devices, even though this is my first printer!). During assembly, the instructions mentioned to twist the z-axis screw by hand to raise the assembly... when I did this I noticed that it I had a tough time raising it. I failed the z-axis test. I loosened all the screws, tripled checked the alignment, and still failed the z-axis test. When it failed, it raised about 30 mm above plate and then stopped. After much more similar tinkering, it passed the z-axis test!

I then started printing. The frog came out well (for a first print). Then I started printing larger objects. The printer would not rise above about 30 mm (despite passing the z-axis test that I continuously conducted) and would continue to print, which would eventually push the piece off after some accumulation on the top layer.

Finally, I took everything apart and moved the trapezoidal nut, by hand, to assess it further. The nut by itself gets caught up at two locations. I can pass the nut with some effort, but it was not an 'easy' thread at these locations. I looked at the threads, tried lubrication (even though I know the nut is self lubricating) and tried many things. It just didn't work for me. I reached out to customer service, sent them pictures, and provided a video (I'll share those here). They will likely send me a new part (I don't know if it will be a nut or a z-motor thread).

I saw some recent dislodging and other height-related issues in the forum and wanted to post this. Even though you may pass the z-axis test, you might want to check the resistance of the threads - especially if you fail at the same height on different prints.

I welcome any comments or suggestions. I'll post a solution once it has been resolved!

https://forum.prusa3d.com/wp-content/uploads/2022/01/20220102_154543_reduced.mp 4" Prints failed at around 30 mm[/caption]

Prints failed at around 30 mm[/caption]

Best Answer by sjwill04:

Update: I received a replacement z-motor with the thread. That seemed to fix my prior issues. The original nuts and the new nuts have a snug translation without significant sticking. It has passed all tests and the prints, so far, have looked good. Thank you Prusa for good customer service!

RE: Dislodge and Z-motor issues

In case the video didn't embed in my above post, here is a YouTube link:

RE: Dislodge and Z-motor issues

By assuming that trapezoidal Z-rod is not bent, then Z-axis movement can only be obstructed by wrong assembled trapezoidal nut. Interesting is, that this is also the case for pre-assembled Mini's (at least it was on my Mini).

For mounting trapezoidal nut...

... manual says:

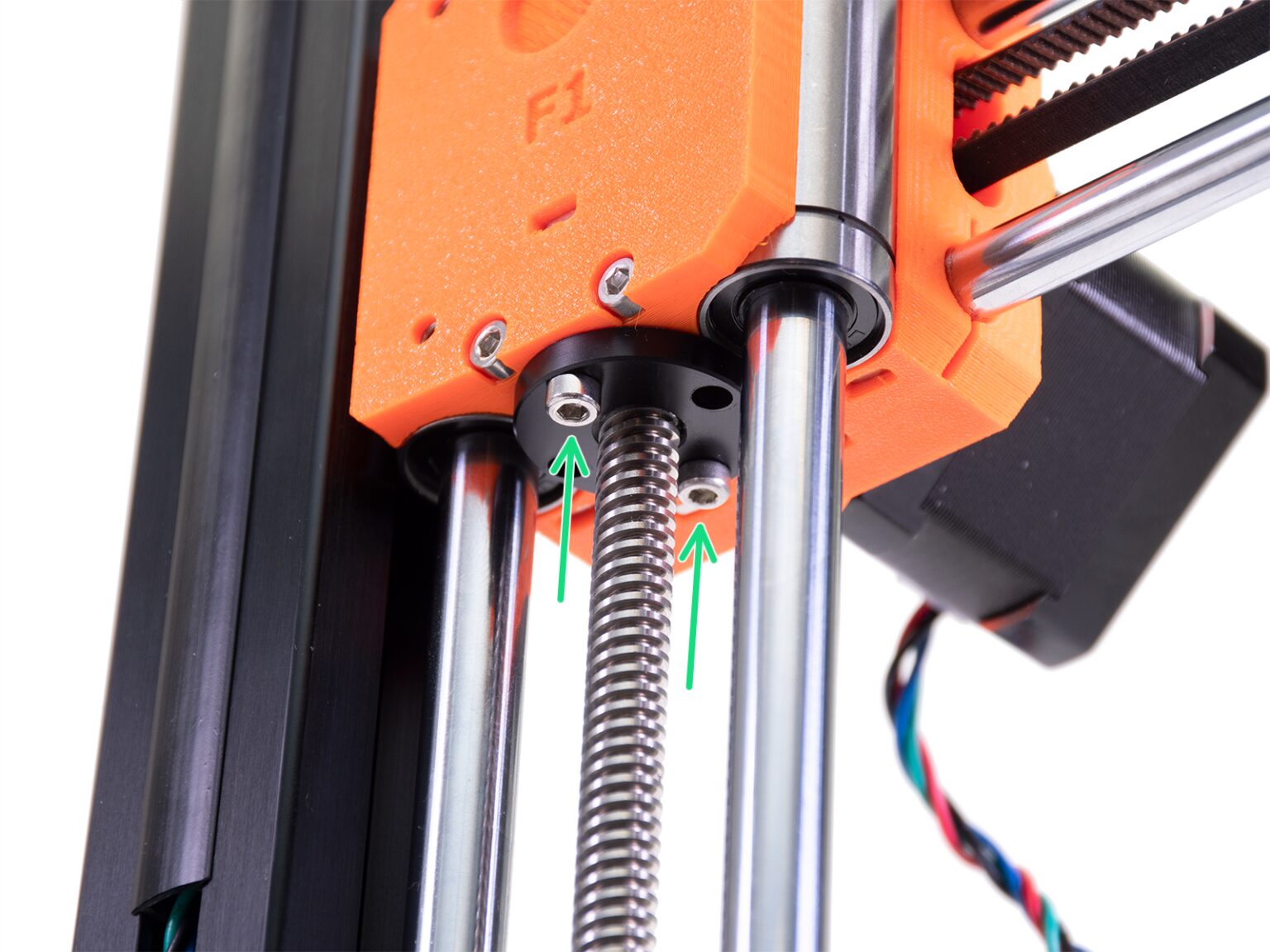

1. Look from below and align two holes in the trapezoidal nut against the holes in the plastic parts.

-here it isn't said which two holes to use (threaded or non-threaded). Correct is: non-threaded.

2. Secure the trapezoidal nut to the X-axis with two M3x20 screws.

-depends on what "secure" means, but it should be added: don't fully tighten the screws -nut must have slight free play.

[Mini+] [MK3S+BEAR]

RE: Dislodge and Z-motor issues

BogdahH is absolutely correct here with regards to assembly. Do not over tighten these screws in his picture, they will add additional resistance.

What I find interesting is that the nut exhibited resistance when it wasn't assembled at all (as shown in the video). Prusa has sent me a replacement part and hopefully that will fix it.

RE:

First, I want to say that Prusa has great customer service. They express mailed me a new trapezoidal nut and it arrived today. Unfortunately, the nut still got caught up in a few areas on the motor thread. Although I have not reassembled the printer, I can almost guarantee that it will fail the z-axis test when I assemble it. Below is the video of me threading the new nut (without anything else assembled to it - just nut and motor only). I will reach out to customer service to see if they have a potential solution. Let me know if anyone else is having this issue!

RE: Dislodge and Z-motor issues

Update: Prusa supplort chat said that they were going to replace the z-motor, I'm waiting on that to process.

While waiting, I decided to try something and it worked. 😀 Out of curiosity, I ordered some other nuts (TR8, 2 mm pitch, 4 mm lead) that are not Prusa's. I threaded them on the z-axis with no significant resistance. Although the threads matched, the location of the fastener holes and other dimensions did not. I had to modify two holes in the new nut to carve a "slot" for proper placement of the fasteners. I have had no issues with my (few) prints so far. Pictures below are of Prusa's nut and the ordered nut (before modification).

This means that my prior problems are either due to (i) the manufacturing of the two trapezoidal nuts provided by Prusa and/or (ii) the threads on the z-motor. Hopefully Prusa will process and replace the z-motor thread (as the service chat said they would) to see if that was the original issue. I'll update this thread if that is the case.

A successful print (middle) compared to prior failed prints.

Comparison of original nut and purchased nut

Comparison of original nut and purchased nut (top view)

RE: Dislodge and Z-motor issues

Looks like I am having the same problem

Support wants to try replacing the nut first, but I think the leadscrew is defective?

RE: Dislodge and Z-motor issues

I've read your post and it closely mimics my experience. If yours was a kit and you feel comfortable, I recommend testing the nut by hand to see if you get resistance at the troubled height.

I'm waiting on them to send me a new motor (and they said they would throw in new nuts), which should arrive in a few days. At that time I can compare old and new nuts with the new motor.

If you contact Pruss they will, at least, send you a new nut. I have some extra of these "other" similarly threaded nuts if you want me to tell you where I got them (or mail you one to test).

I hope Prusa hasn't had a recent bad batch of nuts or threads. But hopefully we can identify the issue.

RE: Dislodge and Z-motor issues

Update: I received a replacement z-motor with the thread. That seemed to fix my prior issues. The original nuts and the new nuts have a snug translation without significant sticking. It has passed all tests and the prints, so far, have looked good. Thank you Prusa for good customer service!

RE: Dislodge and Z-motor issues

Thank you for posting this. I've been struggling with prints failing at almost the exact same height, and like you, my printer passes all the self tests, and I've done all the little things to double check everything is aligned, but I'm still having issues. Anything that never reaches that height is fine, but once I get to where it seems to stick, all prints seem to fail. I guess I need to contact support.

RE: Dislodge and Z-motor issues

If it was just a LITTLE sticky, that could work. Unfortunately, this is a tightening of the nut on the axis rod such that it takes some grip and some force to twist the nut around. Fortunately, Prusa sent me a new Z axis motor and it solved the problem, as above.

This may sound extremely simple, but a very tiny amount of graphite lubricant solved the Z-axis movement problem for me.