Reverse elephants foot issue

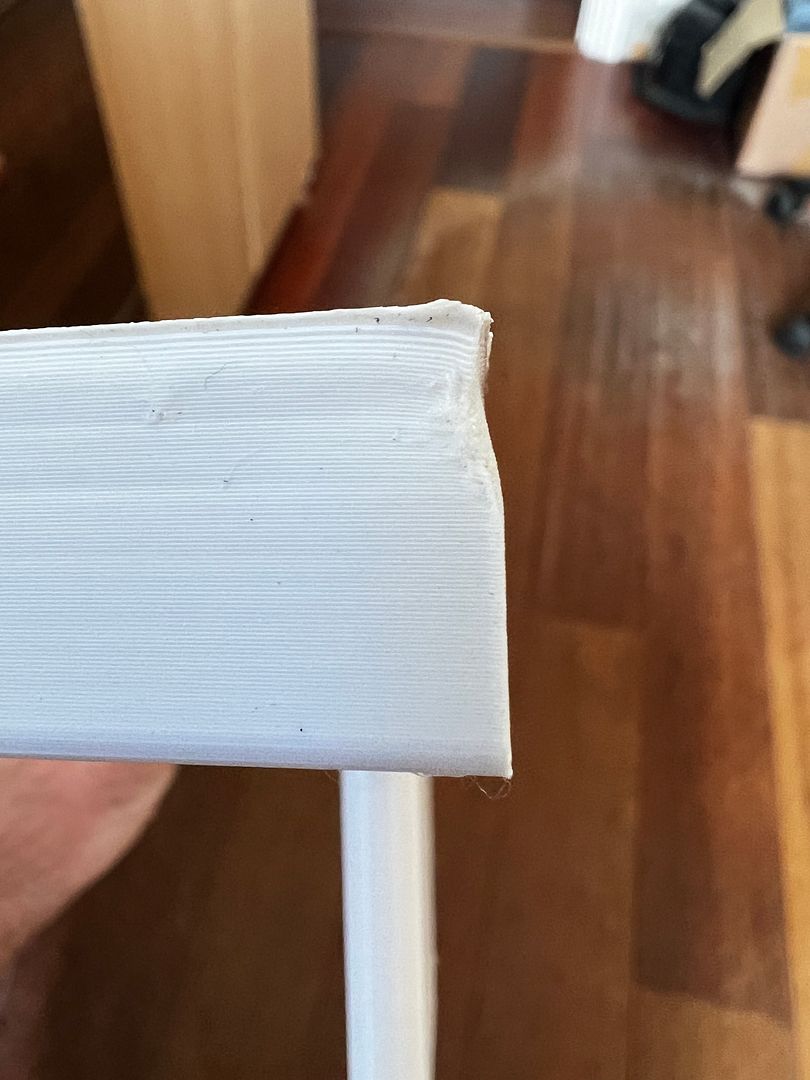

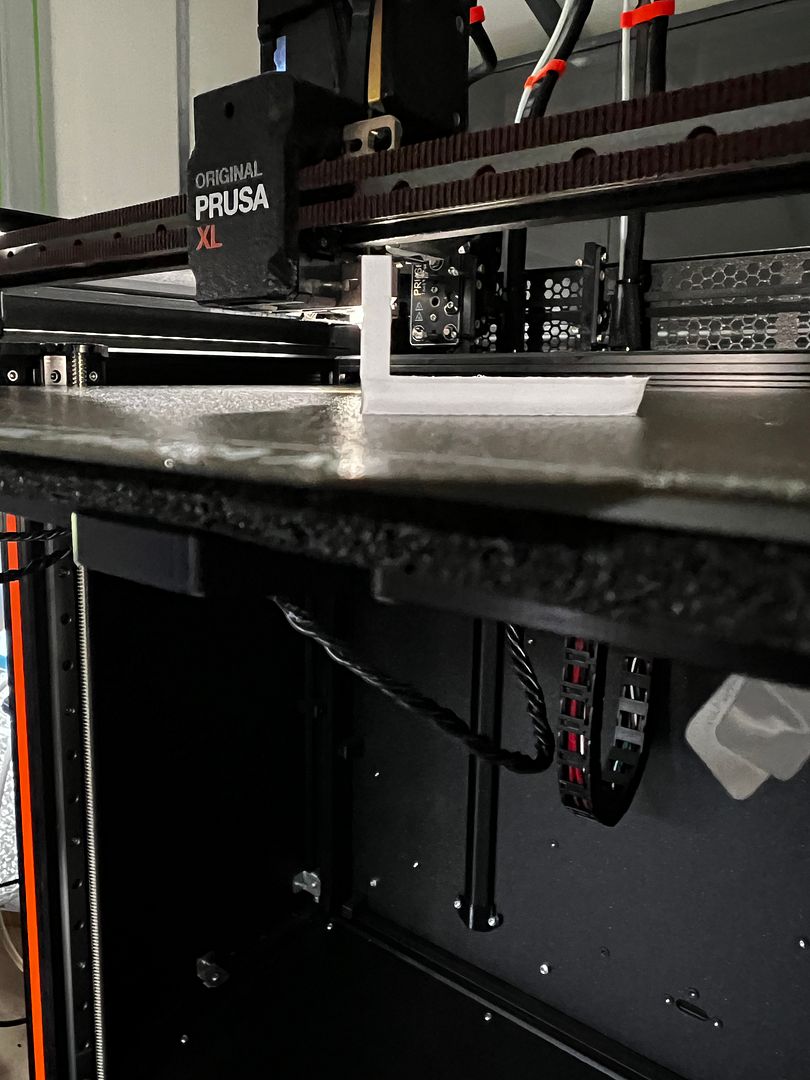

Not sure whats causing this so any advice much appreciated. As you can see, I'm getting this concave section forming on the lower layers but the printer is obviously capable of printing in a straight line as you can see by the vertical section above it.

This is with Prusa PETG and with a 0.4mm hardened nozzle (I have same issue using a 0.6mm hardened nozzle as well).

I've tried printing perimeters first, reduced the bed temp down, changed infill patterns, turned off elephants foot compensation and loads of very small tweaks I've now forgotten!

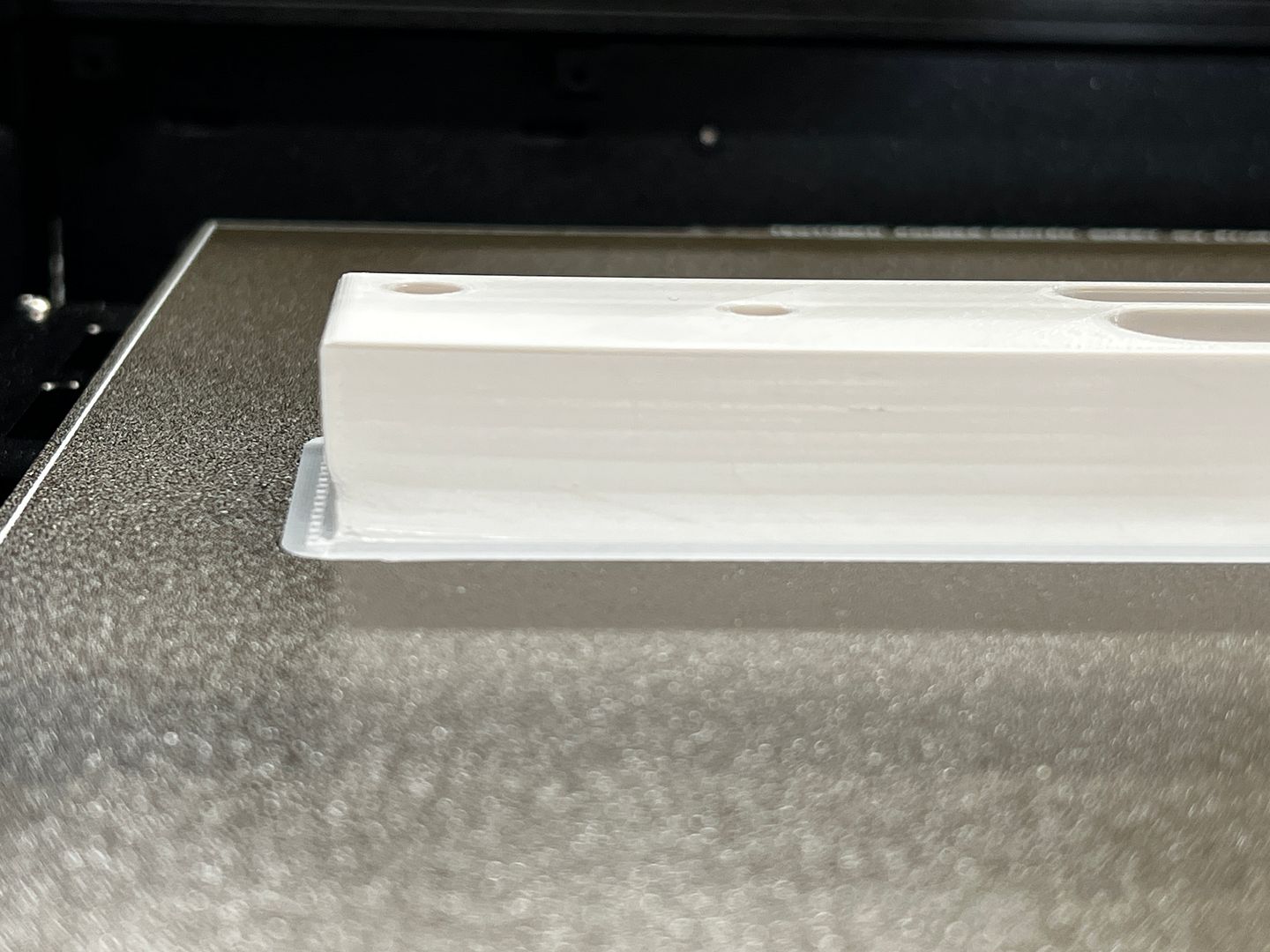

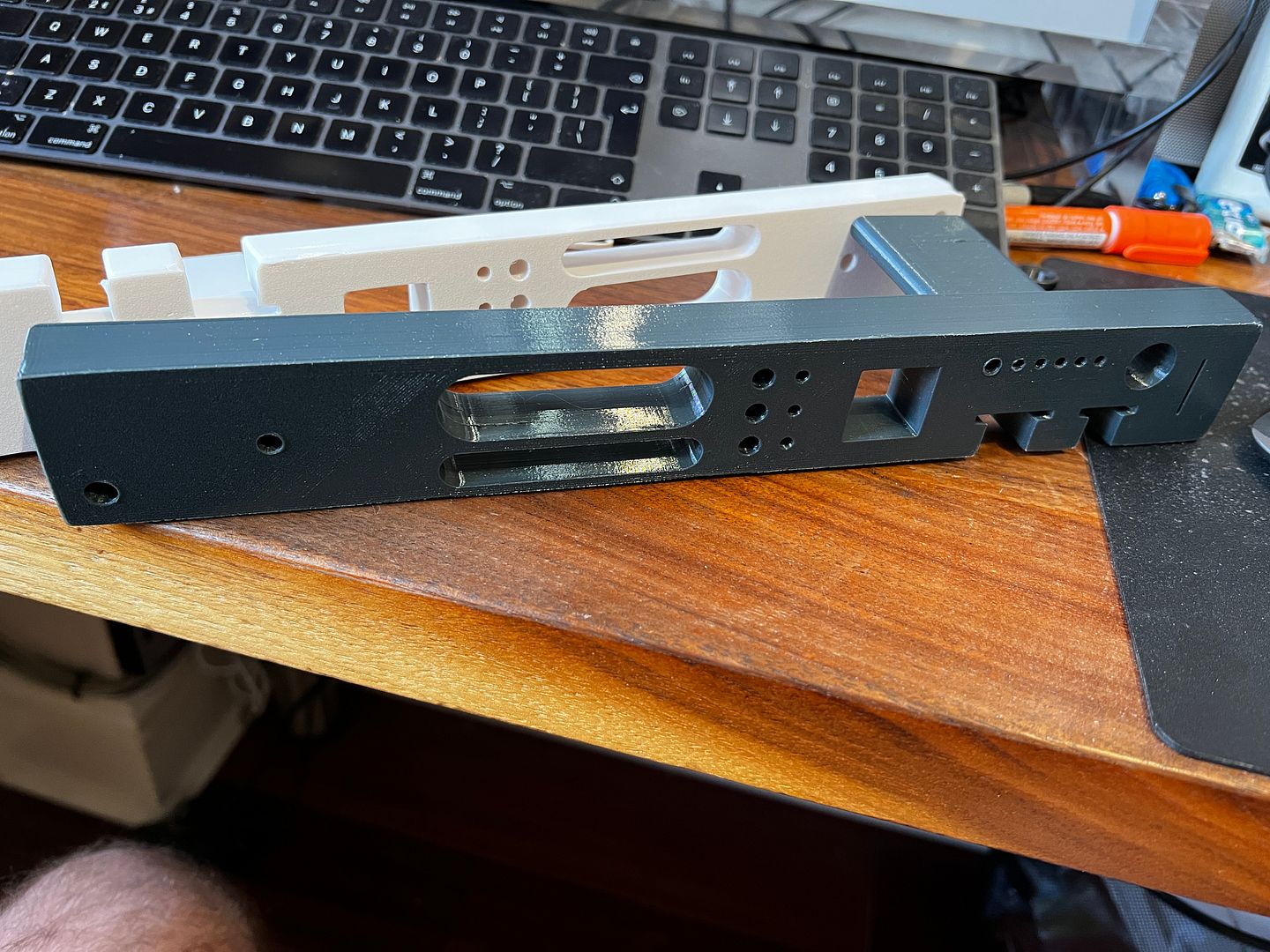

This part was done with a 0.6mm nozzle

It looks like you may be getting some warping that would cloud the issue - please show us the underside of the failed print.

If you would like us to check your settings against the model save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here.

Cheerio,

RE:

Thanks for the response. Here is a (hopefullty!) a zip of the .3mf printer tool holder 6.3mf

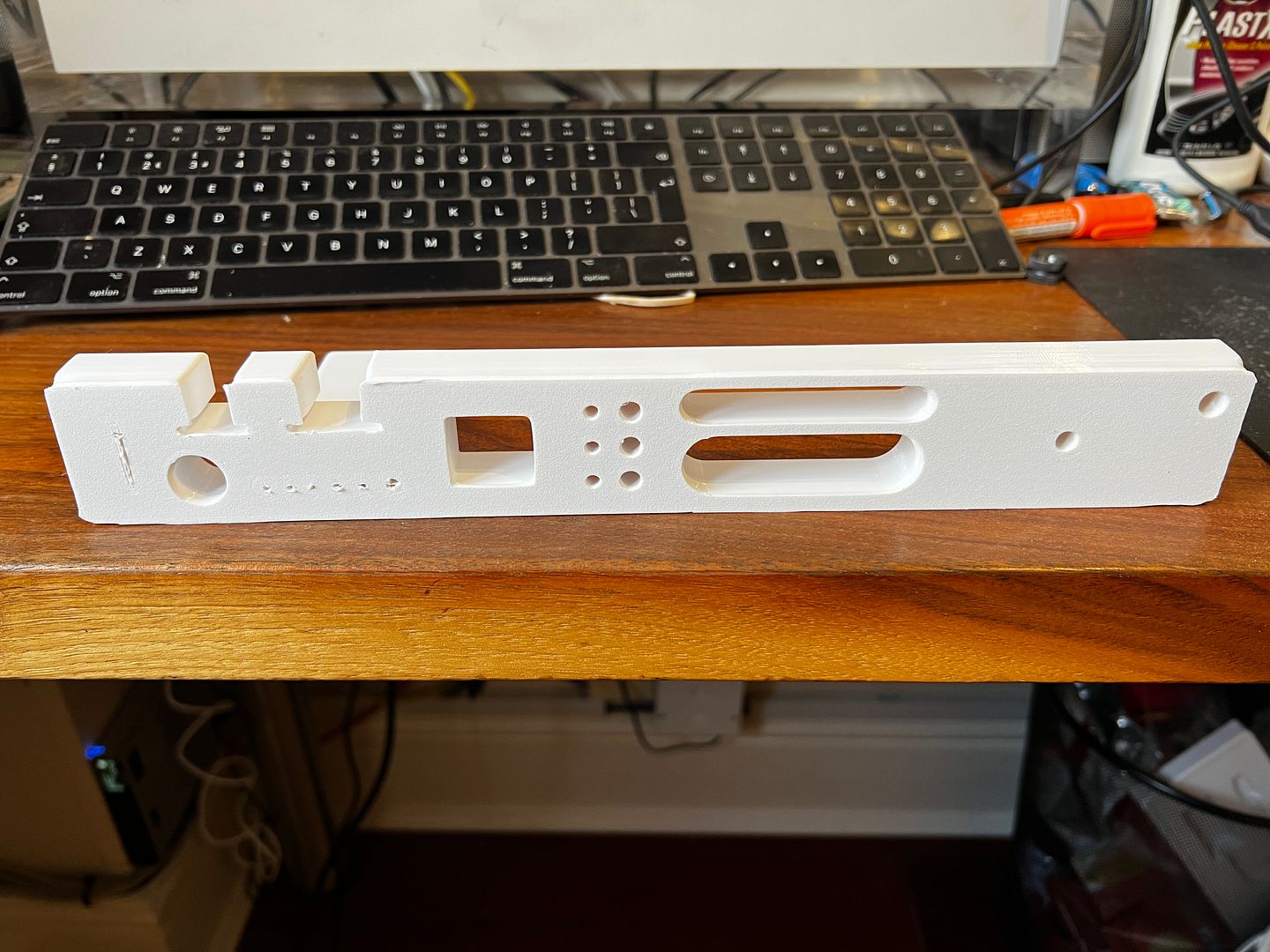

This is the underside (top surface) and yes there is a small amount of warping although I'm definitely getting good bed adhesion and it pulls uniformly off the textured plate.

RE: Reverse elephants foot issue

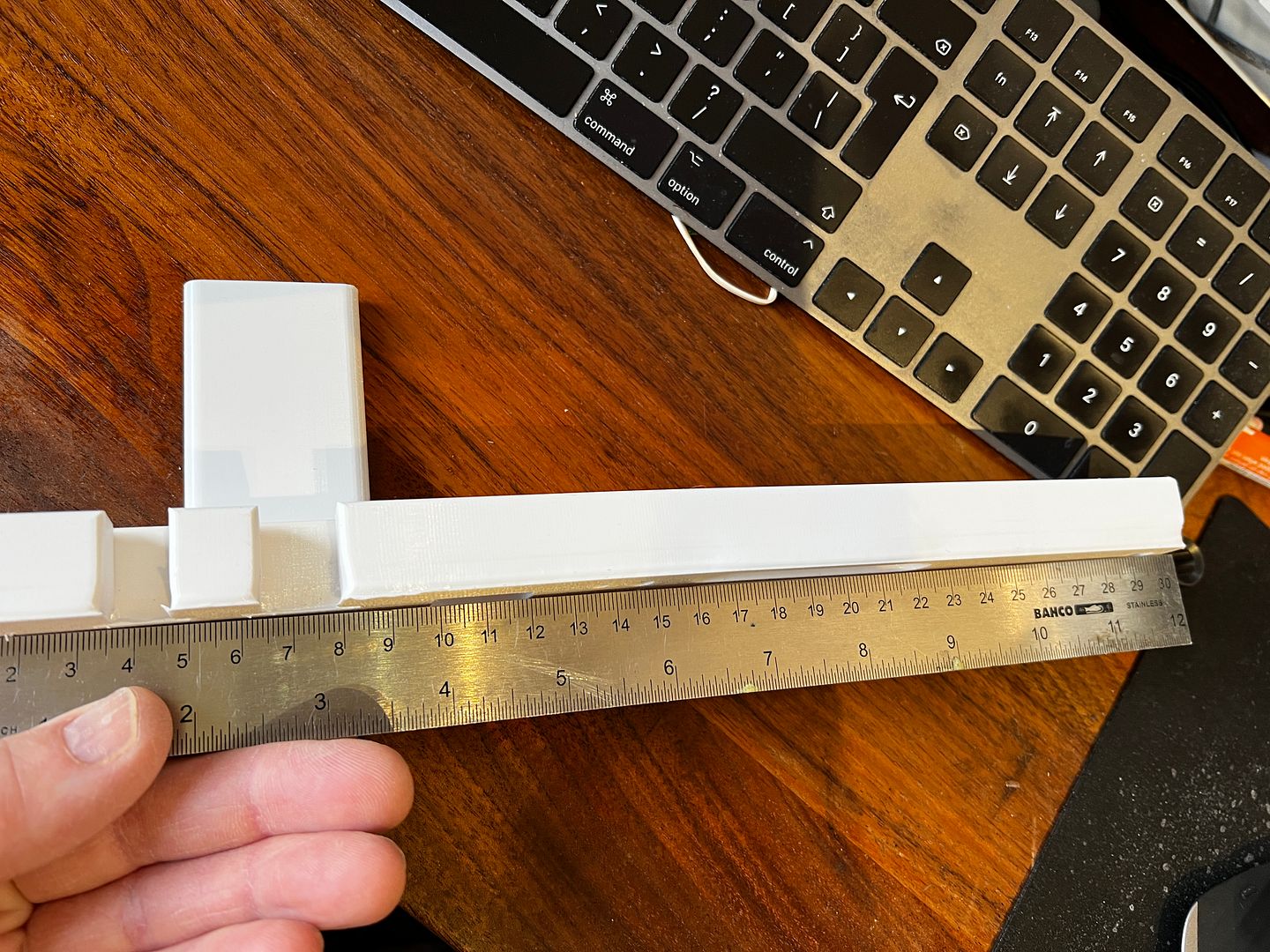

Here's the L profiled part and the warping is not as bad along its length

RE: Reverse elephants foot issue

I took a look at you file. Is there a reason you put a radius on the bottom edge? I would recommend a phase instead of a radius, if that's really necessary. And if you use a radius, use it all way round. In the actual configuration, you see the difference in print speed over layers, and a big jump in print speed on the back where you are not using a radius on the bottom and horizontal edge. In combination with 'only' 20 % infill and two wall layers... Fan speed also changes in those layers. I would try only radii on the horizontal edges, and play with the wall layers.

If adhesion is OK then the warping must be lifting some of the print sheet. As it warps the effective length changes but filament is still extruded where the filament ought to go - hence (some of) the curve.

Long, thick print runs exert huge forces as they cool so the first things to try are:

Protect the printer from drafts - you don't need an enclosure but keep doors and windows closed.

Increase the bed temperature by ten degrees or so.

In most cases I would suggest trying a different infill - but cubic would be my first choice too...

If possible break some of the long extrusion runs with expansion gaps: In your case I would try a few thin, half-thickness slots on the inner sides so that only one continuous perimeter is exerting full warping forces while the other is relieved by several micro distortions where they don't matter.

Let us know how you get on.

Cheerio,

RE: Reverse elephants foot issue

I am seeing the same issue on all my prints and have tried many of the adjustments you also mentioned without luck, did you ever find a fix for this?

RE: Reverse elephants foot issue

I ditched the 0.6mm nozzle and put in a brand new brass 0.4mm nozzle. Hasn't 100% fixed it but its a load better. Still messing about with some settings but another tweak thats helped is to print a temperature tower and I realised my prusa petg filament was happier at 230c instead of the higher temp I had it.