Poor Prints XL multi tool.

HI all I have received my second prusa XL due to the first one has multiple faults with it even after it had been assembled at prusa and tested by them.....

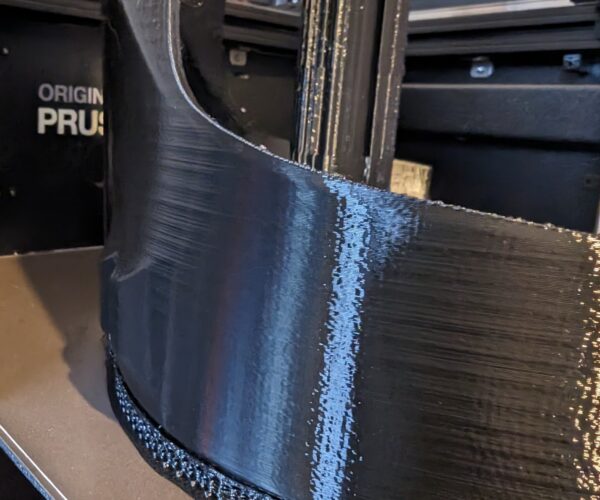

The new prusa xp prints like rubbish i now have bad banding all the way up the prints, again this was pre assembled by prusa, they are not longer replying to my emails which is even more disappointing this whole situation has now put me right off ever purchasing another prusa printer.

RE: Poor Prints XL multi tool.

Have you tried the Helpdesk Chat option, it is generally more immediate, than emails.

Link to this post so that they can see the example of your print,

Chat is available on several Prusa Pages, including this one

https://help.prusa3d.com/downloads

Please note, it takes about 3 seconds to materialise after the page opens.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Poor Prints XL multi tool.

What filament and setting are you using, specifically nozzle, infill and perimeters?

A few optical things. One is that your filament is glossy, so surface defects are going to be highly visible. It also looks like the filament is fairly translucent, which is going to make any infill setting more apparent, especially if your perimeter settings make the walls thin.

That looks like Taulman PCTPE to me, which is very hard to get to print consistently. I’m not saying that the printer is running correctly, just that you could be at the edge of general 3D printing capability. Do you have a Mk3 or mini that could print the same part or part of it with similar settings. That would give us a different hot-end/extruder set-up to compare to.

RE: Poor Prints XL multi tool.

Never use Email with Prusa. They are very conscientious but they are not email people. Always use Chat. It is quick and easy. It just works. Now for the print. Backup so we can get a look at the whole print. What filament are you using. What settings. Lighting is also a factor. It is 3D printing after all. Have you tried the Galaxy black that came with the printer.

RE: Poor Prints XL multi tool.

Sorry you had a bad experience with your first XL. Prusa chat would be the right place to get help with the second one. But let's see if the experts here can shed some light on the situation.

Can you tell us more about what you are printing, how you sliced it, what filament you are using, what profile or print settings you are using? Is that a raft at the bottom of the print?

Whatever you find to do with your hands, do with all your might!

RE: Poor Prints XL multi tool.

The print is using 2 perimeters 5 layers top and bottom infill is %20 rectilinear and is using the standard 0.25 XL prusa profile.

The first prusa XL did not have the issue of Z banding but that one was plagued with bed failures and other faults.

I have printed this file with the same PETG filament on my £350 cheap Chinese printers and it comes out perfect so i know it is not the filament or the file at fault.

RE: Poor Prints XL multi tool.

That is the weirdest PETG I have ever seen. The filament may be 'fine' but does it work with the profile in the XL? Didn't you get a free roll of filament with he printer, or are they giving out some other free-bee? Did you run any Prusament at all? I know that you can print the filament on a cheap printer, but take some variables out of the equation and then build on that.

Is it really as translucent and glossy as it appears?

RE: Poor Prints XL multi tool.

I have tried the PLA filament that comes with the prusa XL, and the Z banding is still there on the prints it is just not as noticeable due to that filament having a matte finish, the PETG in that picture is run on all the other printers I use Bambu's and Ratrigs and the prints all come out nice on them just not on the prusa XL this is the only machine I have that has Z banding.

I have been using this brand of PETG for around 4 years and it is far better than most of the other brands out there.

RE: Poor Prints XL multi tool.

I have been using this brand of PETG for around 4 years and it is far better than most of the other brands out there.

Not all PETGs are compatible with universal settings. It not always the machine, sometimes the issue is the settings the user is using. I will also recommend the chat.

--------------------

Chuck H

3D Printer Review Blog

RE: Poor Prints XL multi tool.

I understand that, but i have used the filament that came with it that was configured to be used with the printer and the banding is still present, I have also printed there pre sliced gcode file with there filament and again the banding is still there.

I do not think this is a settings issue or a filament issue it is hardware, from previous experience I have never seen Z banding like this down to anything other than hardware or how a printer has been assembled.

RE: Poor Prints XL multi tool.

I have never had this type of Z Banding with a Prusa Machine that was assembled and used correctly. You might be right and you might be wrong.

Your time would be better used connecting support than defending your views on the forum.

I understand that, but i have used the filament that came with it that was configured to be used with the printer and the banding is still present, I have also printed there pre sliced gcode file with there filament and again the banding is still there.

I do not think this is a settings issue or a filament issue it is hardware, from previous experience I have never seen Z banding like this down to anything other than hardware or how a printer has been assembled.

--------------------

Chuck H

3D Printer Review Blog

RE: Poor Prints XL multi tool.

It’s always tough to balance working with a manufacturer and getting help from the community. Prusa may be better than most, but often a community can sniper a problem- and give multiple paths forward.

My next question was going to be a more simple structure, with Prusament, with a Prusaslicer profile- which it sounds like you did and you still see it.

The printer should print at .25 nozzle, but maybe try a .4 or .6? Frankly with my MK3 and MINIs, anything other than the 0.4 nozzle prints kind of funny. I think it is the flow settting and rheology not playing well together.

What layer height?

I also notice that the top ‘seam’ in the curved part looks white? Like the filament isn’t printing well? Like it might need a bit more heat?

Good luck.

RE: Poor Prints XL multi tool.

The first thing that comes to mind when I look at the picture is that one of the Z spindles is crooked.

This is because there is a repeating (Z) pattern in the object.

I don't have an XL myself so I don't know if a nut is used in the bed.

If that is the case, you may want to loosen the bolts holding the nut slightly.

RE: Poor Prints XL multi tool.

The print is using 2 perimeters 5 layers top and bottom infill is %20 rectilinear and is using the standard 0.25 XL prusa profile.

The first prusa XL did not have the issue of Z banding but that one was plagued with bed failures and other faults.

I have printed this file with the same PETG filament on my £350 cheap Chinese printers and it comes out perfect so i know it is not the filament or the file at fault.

When you say that you have printed this file before on another machine, do you mean the g-code? Or do you mean the mesh file? If you mean the mesh file, are you slicing it in Prusa Slicer? Is it the latest version with the latest print profiles? Did you find a filament profile for your specific PETG, or are you using a generic filament profile?

Whatever you find to do with your hands, do with all your might!

RE:

The first thing that comes to mind when I look at the picture is that one of the Z spindles is crooked.

This is because there is a repeating (Z) pattern in the object.

I don't have an XL myself so I don't know if a nut is used in the bed.

If that is the case, you may want to loosen the bolts holding the nut slightly.

I second this, especially since it seems to become worse with increasing height and it's something that could get damaged in transit. I'd systematically check both spindles (is anything loose, check straightness with a ruler, is the bed tilted between left&right spindle). It definitely looks like it repeatedly builds up resistance. Print a calibration cube as a simple check, if it's missing some height you found your problem. Did the factory test print look ok on the sides? You could also carefully release the screws that hold the Z linear rails, then move the bed up and down manually, trying to find the best rail orientation. Maybe they're installed wrong or even some screws are not tightened (do so at your own risk, it can be frustrating to properly align linear rails). Spindles and rails need to be 100.00% parallel, at 90° to the bed and exactly the right offsets.

That said, I've seen the same behaviour also with bad filament, lingering heat creap issues and broken nozzles. It doesn't mean much that the filament prints well on another printer unless the temperatures, nozzles diameters and feed rates are exactly the same (which is hard to confirm). I have a roll of PLA that will reproduce your issue on every printer I throw it at 🤑

If you think you really eliminated the first by trying known-to-work filament, check the part cooling fans (installed correctly, noise, no wires in the way). Internal nozzle blockage can be hard to diagnose, I'd start by manually pushing filament through at slightly higher temperature. Sometimes you get these problems when a bit of residual higher temp filament is stuck somewhere inside, but that is mostly due to incorrect assembly which leaves small gaps somewhere. By design it shouldn't happen here unless you're using the standard nozzle adapter.

RE: Poor Prints XL multi tool.

And this being the multi tool version, do you get the same results with every tool head.

did I read right that you were printing at .2 with a .25 nozzle? That should work but I think you’re at the upper bound for layer height.

RE: Poor Prints XL multi tool.

did I read right that you were printing at .2 with a .25 nozzle? That should work but I think you’re at the upper bound for layer height.

I can only find the layer height, and it is 0.25mm.

The nozzle size is not mentioned anywhere,

so I assume the nozzle of the XL is 0.6mm.

This is the size the XL is delivered with, I think.

RE: Poor Prints XL multi tool.

I think it is a hardware issues, going over the printer the left Z rod looks like it is wobbling around like mad, i have loosened off the screws and re tightened them and it still wobbles which makes me think that the rod must be bent or something is misaligned, i have added a link to a video showing what I mean.

RE: Poor Prints XL multi tool.

That's what I meant, contact Prusa and show them the video.

They will probably send you a new Z motor.

If you can't or don't want to assemble the motor yourself,

the only option is to send the XL printer back to Prusa.

RE: Poor Prints XL multi tool.

Defintely looks that way. As said above (Rene), contact support and share this video.

I think it is a hardware issues, going over the printer the left Z rod looks like it is wobbling around like mad, i have loosened off the screws and re tightened them and it still wobbles which makes me think that the rod must be bent or something is misaligned, i have added a link to a video showing what I mean.

--------------------

Chuck H

3D Printer Review Blog