Nozzle Cleaning Failure Solved, for now.

Hi Everyone,

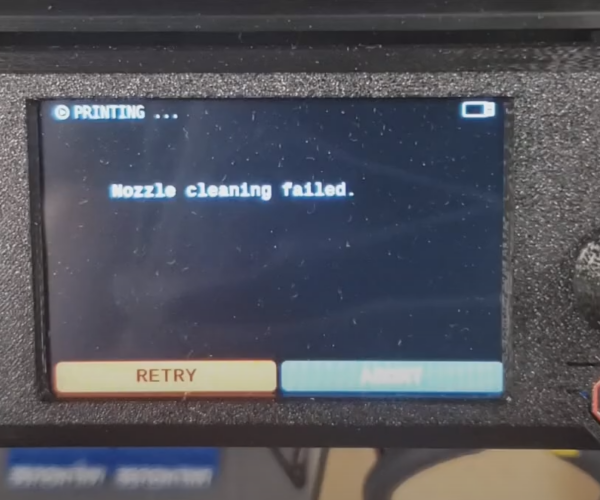

So I was getting nozzle clean failures in my XL and it was causing me to not be able to print. I did not have any other printers running or vibration happening in the farm when this was happening. It was not until I started digging into the calibration and tests settings that I figured out what was happening.

When I was testing the nozzle loadcell test, I noticed that it took a lot more pressure from my finger to get it to register. The issue was that I had installed the silicone socks on my nozzles and they are rubbing against the part cooling fan duct.

I removed these silicone socks from the nozzles and the loadcell test was back to normal and I was back to printing normally.

I like these socks as they keep the nozzle temp more consistent and clean, so that is a bummer. I looked and I don't think I can safely rotate the nozzle away to give the socks more clearance, so they will remain off for now.

I just wanted to give everyone a heads up on this. Let me know if you are able to find any solution to this as well.

Thanks,

--Scott

RE: Nozzle Cleaning Failure Solved, for now.

I had issues with the socks not fitting all the way on. I solved this by loosening the screw that holds the nozzle/hotend on and rotating the hotend away from the fan slightly and then holding it there while I tightened the screw back down.

RE: Nozzle Cleaning Failure Solved, for now.

Can you not just cut out the part of the Sock that touches? I personally would try to change the Sock not the Printer.

RE: Nozzle Cleaning Failure Not solved.

I'm keep getting a nozzle cleaning failed. And I do not have the sock installed. Anyone find a solution or have this issue.

RE: Nozzle Cleaning Failure Solved, for now.

I had issues with the socks not fitting all the way on. I solved this by loosening the screw that holds the nozzle/hotend on and rotating the hotend away from the fan slightly and then holding it there while I tightened the screw back down.

It's not obvious the bolt to release the nozzle is hidden behind the toolhead quick-release plate. There's a hole in the plate for an allen key but it's not marked anywhere on the plate and it's only documented once (that I could find) in the instructions. But once you know about it it's extremely convenient on the multi-tool XL to manually undock the toolhead and adjust the nozzle. Much easier than on a MK4 when its attached to the X axis.

Silicone socks on both my nozzles now. Needed 5 degrees clockwise rotation to avoid fouling exactly like OP found. Prusa should be shipping their nextruders with the correct rotation to avoid this issue.

RE:

If youre getting the nozzle cleaning error and you know its not the thermal sock inhibiting the load cell I suggest you try this:

Go to the Print settings menu in the plate view (the pull down with the quality presets… on the right side of the screen) and select a preset setting. I switched it from “Fine” from a previous print to Speed and it worked perfectly after nothing else worked. This was the third time for me that I found an issue that was immediately solved once I selected from this pulldown. I suspect PS is not resetting the print settings as we would assume it would. In one instance I found it retained all the settings from a previous print using a completely different 3d printer! If this is the case it would explain a lot of the issues we’re seeing including SeattleDaves battlebot post.