RE: XL full enclosure

Reading this thread, I am so glad that when I built my workshop, I put in exhaust ducts at all locations where there would be fumes generated. Now I just need to control the air flow from the enclosure. FWIW, I am still a great fan of lead based solder for electronics as it seems to work much better than any no-lead based version I have tried.

RE: XL full enclosure

I have been considering this for a while...

XL chassis is made out of extruded aluminum profiles, right? It wouldn't be so hard to slap some side extension panels (taller than toolhead wires) with just some bolts, some doors, a roof, and a rear panel to the toolheads, and voila! An enclosure is made!

Thing is, will this introduce resonances? Is it better for an enclosure to be detached from the printer? I mean I keep hearing XL is rock solid.

I was wondering because this thing is big. If you leave a gap then its size is gargantuan.

Any thoughts?

RE: XL full enclosure

For me, that seems like we definitely need / want an enclosure, already for big PLA parts:

RE:

Enclosures for PLA aren't exactly a great idea. You are truly provoking clogging issues with rising chamber temperatures due to build plate and hotend heat. What I found helps against warping of very wide and shallow PLA parts is reducing bed heating to a minimum (eg 40°C) and use adhesive if bed adhesion becomes an issue. If it is with such big flat prints still an issue, use brims. Generally printing so close to the edge is always challenging. If you leave at least 1 cm you can invest in a 1 cm brim.

Parts might still warp when cooling down but one can prevent detaching from the plate already during the print.

PS: For most materials other than PLA enclosures are definetely very recommended.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: XL full enclosure

Or perhaps this is something needed to print large PLA objects??

I mean, the XL came after the MK3 enclosure, so they could have made it enclosed or made an enclosure, but this accessory above never really made much sense to me. ABS and others need an enclosure to keep the heat. Also, it makes more sense an enclosure to keep energy consumption down (And the split heat bead tell us they were looking to keep energy consumption down).

However if we look at the XL, when is printing is only open to the top and front. Those upper arms guard the print against side drafts, but as the bed moves down... The print gets exposed to side drafts potentially creating the issues we see on the video, in my humble opinion...

Maybe they created this draft skirt (don't know what to call it) for those large PLA prints where you want to avoid warping (or coming off the bed) but they didn't want to raise the temp...

However, I believe a well-designed enclosure, with constant air flow when printing PLA either venting out or filtering it should do the trick. Also using glue stick in large prints never hurt anyone... I will keep that in mind for large prints...

RE: XL full enclosure

Hey all!

I'm a tinkerer, engineer, fabricator, and a guy who just happens to have some experience in this area.

I'm going to make my own enclosure for the XL since it will likely take Prusa a bit to release their own. What price point would anyone be willing to pay for such a thing? Is anyone interested / is it worth doing? I know of two potential solutions, one is ungodly expensive (but allows the XL to be stackable) the other is less expensive and can ship in a rather small box.

I can probably crunch a few out if people need them if I design it well. Right now I'm just waiting on getting my launch-day ordered XL and I'll be waiting for the multi-head version because why not.

RE: XL full enclosure

Are you thinking about something that integrates with the frame of the XL or a separate box that covers it?

RE: XL full enclosure

Both designs integrate with the frame, a separate box would be insanely huge, not to mention expensive.

Ill post pictures once I get my XL and build a prototype.

RE: XL full enclosure

I've got a 5 extruder xl on order, I'll be interested to see what you come up with. the draft shield we've seen in prusa's demos definitely seems useless for things like ABS/ASA etc. I have full enclosures for my two MK3S+ machines with the ventilation kits. The enclosures, light and ventilation kits are from these guys.

RE: XL full enclosure

There are additional issues I have with their draft shield, but I agree, it's fairly useless unless you have absolutely no airflow nearby.

I have a 1 tool head on preorder and will be upgrading it to 5 when my spot in line comes up. I ordered it on release day, so I'm hoping that means I can get it this year.

RE: XL full enclosure

yeah, I preordered the 5 extruder model on day one so I hope that some time in may it might show up lol. I already printed the upgrade parts for my 2 mk3s+ printers so now it's a waiting game lol. I'm living vicariously through those that have gotten the XL lol

RE: XL full enclosure

A fan and dryer hose will pull the fumes out a window. Like this: https://www.printables.com/model/18703-3d-upfitters-prusa-enclosure-additions

If you have a window. Mines in a basement.

RE: XL full enclosure

I'm definitely hoping for an enclosure by the end of the year when my preorder comes up. Like some others I am printing in my house and run the filtration on the enclosures of my 2 MK3S+'s.

It makes a difference not only for VOC reduction when printing materials like ASA, but the prints don't seem to suffer from warping like they do without the enclosure. I have a friend with the exact same setup as mine minus the enclosure and they struggle with ASA, ABS etc whereas I don't.

I usually heat the bed for about 30 minutes prior to printing which brings the temp up to about 35°C inside the enclosure before printing. It would be nice to get it hotter but this has sufficed up to this point.

So to summarize I'd like to do the same with the XL.

RE: XL full enclosure

- Humidity control for the currently mounted spools rather than the actual build volume (like the Bambu Lab AMS).

- The external PSU/LCD is predicated on the assumption that it is required to extend working life, since those components would likely be subject to failure if inside a heated enclosure.

- Heating/HEPA filtration to enable safe use of ABS/ASA filaments that require high chamber temps and produce dangerous VOCs

- Stacking/Locking/Fire suppression to me are all more targeted to print farm use cases

RE: XL full enclosure

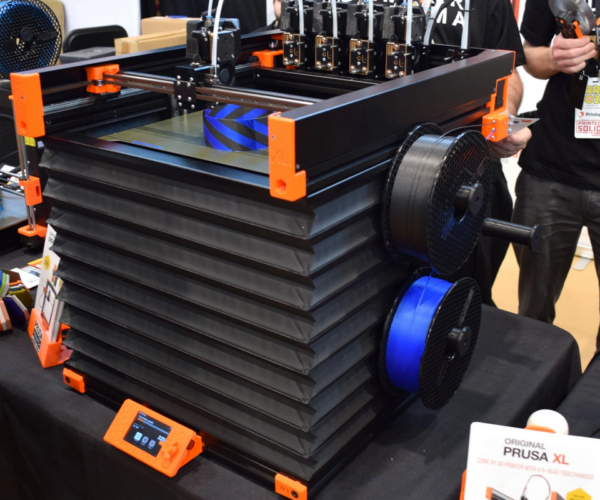

This looks like a great option:

RE: XL full enclosure

Looks good! Worthwhile to make for sure.

RE: XL full enclosure

Indeed, I particularly like the great visibility of this design. Would probably need a better seal on the doors, but overall I like it. and has space on the top part to mount a filter.

It's also worth watching this other guys progress...

https://www.youtube.com/shorts/LY79w1wFlYY

And

https://www.facebook.com/groups/448236529851257/user/100001234237538

Can't really explore either possibility yet since I am still on the waiting list... But it seems to me be the biggest hurdle is the back of the printer...

Prusa went from a flat panel to a hexagonally perforated one for the multitools...

Apparently heat produced by those toolheads could be an issue if fully enclosed?? On the other hand... is a pretty big gap to leave open. I guess I will have to run some tests when I get mine...

RE: XL full enclosure

Typically, there is no need to seal them.

Indeed, I particularly like the great visibility of this design. Would probably need a better seal on the doors, but overall I like it. and has space on the top part to mount a filter.

It's also worth watching this other guys progress...

https://www.youtube.com/shorts/LY79w1wFlYY

And

https://www.facebook.com/groups/448236529851257/user/100001234237538

Can't really explore either possibility yet since I am still on the waiting list... But it seems to me be the biggest hurdle is the back of the printer...

Prusa went from a flat panel to a hexagonally perforated one for the multitools...

Apparently heat produced by those toolheads could be an issue if fully enclosed?? On the other hand... is a pretty big gap to leave open. I guess I will have to run some tests when I get mine...

--------------------

Chuck H

3D Printer Review Blog

RE: XL full enclosure

Are you refering to the doors or the back panel hexagonal opening?

Typically, there is no need to seal them.

RE:

[...]

https://www.facebook.com/groups/448236529851257/user/100001234237538

[...]

Cool - you found my post!

Still working on the stuff, printing the parts myself to make sure everything should fit. But I can give you a first glimpse at the manual and how it is built together, see attached DRAFT manual =)