SLA support questions - including "greyscale" curing and variable retraction speed

I'm about to buy an SLA printer (having for nostalgic reasons continued to modify and use my original triangular since Joseph first published the plans, but about to need higher resolution for a new project). However am wondering about supports and model orientation which seem to be very primitively managed by SLA slicing software (and makers), and wondering if there is any software/firmware combination I can use to experiment with this.

I'm unclear why the SLA printers don't use a greyscale file format to only partially cure support voxels - ie a 50% gray voxel could be exposed for 1/2 the time or half the intensity of a 100% (full white) voxel before the next move. I would have thought a partially cured voxel could still provide support but would be weaker and therefore provide a shear plane to allow easier removal of supports, and perhaps even one which could be tuned to be automatically broken by frequencies from an ultrasonic cleaner, or dissolved by IPA.

This should mean that even single voxel islands could be supported and safely extracted by fully curing the ring of 8 voxels below it while only partially curing the voxel directly below (-z) and lateral (x/y) to it.

Then, given the voxel file format, it should be fundamentally very easy to start at the last (highest) voxel and calculate the tearing force it would exert on the voxels directly under it when releasing from the FEP. You could then sum the support strength of fully/partial cured nearby voxels to establish the minimum cure level required to support that voxel and repeat down the model until you get to the base support layer. Progressively averaging larger sized blocks of voxels should then allow quite rapid automatic calculation of a strong support mesh using non/partially cured voxels with a wide contact area with the model which are then in turn supported by by a fully cured web of sprues starting from the next voxel out. Potentially cloudsourced/pretested larger support shapes could developed with their own internal fracture points and washout channels. This might be possible to have supports which are strong during printing, but have significantly weaker attachment to the model after ultrasound or IPA exposure. Actually even without a greyscale format that should be mostly possible to create supports that way, so it seems really odd to me it's not already done and I'm not clear what fact I must be missing (I don't want to waste my time working on something fruitless).

Finally I'm not sure why the printers appear to have a fixed rate of lift for every layer - surely if a layer has a larger surface area it would make more sense to slow down the retraction for that layer so as to keep the traction force on the previous layers below a fixed range - this should enable an increase in overhang angle or bridging distance. It could be easily defined by the slicer using a fixed greyscale pixel in each layer to encode the retraction speed (column x0,y0 isn't normally used in a print so should be good). Even if a second layer retraction file was required for the print this should be able to decrease print risk. Also there seems to be a lot of advice to tilt layers to mimimise inter-layer shear due to traction force but the raft layers are generally much broader (and therefore breach this general advice from the outset), however if retraction speed could be controlled and shear planes build in to the print then such considerations might be unnecessary anyway.

PS I take it there's an obvious reason everyone doesn't just shine a UV lamp over their workspace overnight to avoid the sticky mess that is regularly complained about as "getting everywhere" (or is is just that good procedures make that redundant).

Thanks

David

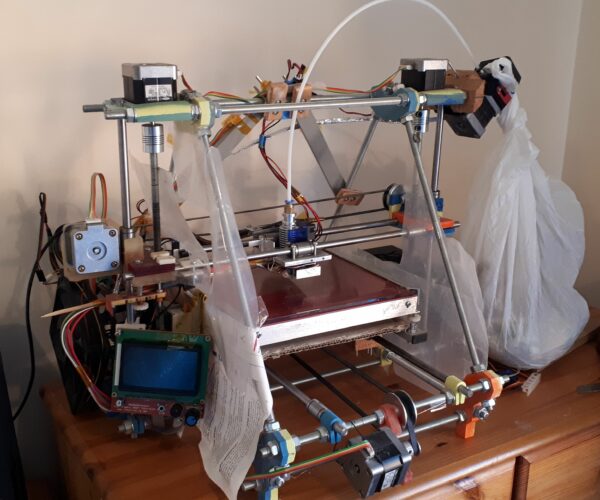

PS Thanks Joseph - it's still alive and well...

RE: SLA support questions - including "greyscale" curing and variable retraction speed

David - Those are great ideas. I couldn't help thinking how much I'd like to see them implemented. Now, we need someone to grasp the nettle and do something about it!

I don't tilt my models, instead printing them directly on the print bed. Saves resin, saves time and I end up with a nice flat surface. Both test prints (Prusa and Prusa army) are printed directly on the print bed, which proves on a larger scale that printing directly on the print bed works. What would be helpful, is if PrusaSlicer would automatically generate supports where required, but not under the base of the model adhering to the print bed.

My SL1 and CW1 are out on the verandah where they get a dose of strong direct sunlight each morning, and yet they remain sticky unless I clean off the resin. I don't understand why as the UV from the sun is much stronger than the UV from the CW1, and yet (after I wipe off the cleaner) my prints are no longer sticky

RE: SLA support questions - including "greyscale" curing and variable retraction speed

Thanks Michael

I have started a conversation with the UVTools dev as this seems like a product which is already nearly capable of these options, and I suspect there is little chance of influencing the closed-source slicers. https://github.com/sn4k3/UVtools/discussions/176

Actually though since PrusaSlicer is based on the opensource Slic3r then this might be a good product to consider

After your comment about the sun I realised the issue is probably UV penetration - resin is presumably designed to be absorb UV in a short distance to prevent bleed of the curing process. Thus because of the opacity in the UV spectrum even the sun can presumably only cure a very thin layer which then fractures when you touch it and exposes the sticky uncured resin underneath.