RE: Resin Leaks between tank and frame

I can definitely confirm you can buy silicone sheets as thin as 50 microns, and probably thinner. 100-200 micron is probably the thinnest that's not a complete nightmare to handle.

Good luck handling them though, that stuff is worse than wet spaghetti, stretchier than you can imagine, and likes to wad up and stick to itself worse than plastic wrap. On top of that it's so thin you will tear it trying to get it separated again.

RE: Resin Leaks between tank and frame

@ryan-c29

McMaster-Carr is my usual source. I have a CO2 laser and have cut engine gaskets in Teflon that was a thin as 0.005". The main issue was keeping sheet that thin flat during the cut. Silicone might be easier in that regard as it is a more "grippy". It cuts fine, though usually leaves a bit of residues but that washes off pretty easy. If you have a DXF or 3D design for the gasket I can try to cut a couple out for you to test. Let me know and I'll provide an email address.

Do you think that a 0.005" thin sheet will really take away enough screw engagement to cause problems? Do you know what the screw form is for the vats?

RE: Resin Leaks between tank and frame

@michaelhenry

Grip from the screws isn't the issue. The issue is keeping the head of the screws under the plane of the FEP so that the tank sits on the platform properly. It is a tight tolerance, but I doubt 0.005" will cause an issue. I do wonder it it will be enough to create the desired seal though.

RE: Resin Leaks between tank and frame

@michaelhenry

Grip from the screws isn't the issue. The issue is keeping the head of the screws under the plane of the FEP so that the tank sits on the platform properly. It is a tight tolerance, but I doubt 0.005" will cause an issue. I do wonder it it will be enough to create the desired seal though.

https://www.mcmaster.com/90358A006/

Just get some of those.

RE: Resin Leaks between tank and frame

@michaelhenry

Grip from the screws isn't the issue. The issue is keeping the head of the screws under the plane of the FEP so that the tank sits on the platform properly. It is a tight tolerance, but I doubt 0.005" will cause an issue. I do wonder it it will be enough to create the desired seal though.

https://www.mcmaster.com/90358A006/

Just get some of those.

Yeah was thinking about something like that. $3.83 each for as many as we need (22), however, adds up quick🙀

RE: Resin Leaks between tank and frame

@michaelhenry

Grip from the screws isn't the issue. The issue is keeping the head of the screws under the plane of the FEP so that the tank sits on the platform properly. It is a tight tolerance, but I doubt 0.005" will cause an issue. I do wonder it it will be enough to create the desired seal though.

https://www.mcmaster.com/90358A006/

Just get some of those.Yeah was thinking about something like that. $3.83 each for as many as we need (22), however, adds up quick🙀

Doh, thought I linked the 50 pack. Usually that's like $8.

RE: Resin Leaks between tank and frame

Heard back from support this morning and they want to replace one of my tanks (I responded back that I showed them 2 that are failing in the same manner) and they asked me if I installed the FEP correctly.

Interestingly they asked me if I followed https://help.prusa3d.com/en/guide/4-electronics-lid_11824#13568 which differs from https://help.prusa3d.com/en/article/fep-film-replacement_1963 (circular vs crisscross pattern). It is the later that I followed since that is what comes up when searching the KB for the process.

Paraphrasing with some artistic liberties due to my current mood, their response was:

We're sorry that you followed the easily accessible directions that we put in our Knowledge Base specifically for users to find when looking for information, but we don't want to send you new tanks until you waste more FEPs following these other instructions.

...

RE: Resin Leaks between tank and frame

@gnat

Yup, told me the same thing. In addition said "I have reviewed the case with our developers. The holes being scratched is a known fact and this is just fine." Which I guess is true until those holes randomly stretch too much, then it's not just fine, it's a bigger leak than the slow leaking we see from the poor seal.

RE: Resin Leaks between tank and frame

@ryan-c29

Well if the lip was correctly sealing the stretched holes indeed wouldn't be an issue. Though if it continues to stretch after the installation process is complete (which is completely reasonable given the tension) that would allow it to loosen up and thus break the seal. The question then becomes if it can maintain enough tension to create the seal longer than a reasonable lifespan for the FEP. (e.g. going cloudy or getting too scratched up)

RE: Resin Leaks between tank and frame

Heard back from support this morning and they want to replace one of my tanks (I responded back that I showed them 2 that are failing in the same manner) and they asked me if I installed the FEP correctly.

Interestingly they asked me if I followed https://help.prusa3d.com/en/guide/4-electronics-lid_11824#13568 which differs from https://help.prusa3d.com/en/article/fep-film-replacement_1963 (circular vs crisscross pattern). It is the later that I followed since that is what comes up when searching the KB for the process.

Paraphrasing with some artistic liberties due to my current mood, their response was:

We're sorry that you followed the easily accessible directions that we put in our Knowledge Base specifically for users to find when looking for information, but we don't want to send you new tanks until you waste more FEPs following these other instructions.

...

They have relented. They are going ahead and sending new tanks and FEPs, but they are still asking to try the other process (and they are including FEPs to account for the waste).

RE: Resin Leaks between tank and frame

Did the circular install test for them over night. The good news is that I didn't have to wait as long for results as I found the tanks leaking after only an hour.

RE: Resin Leaks between tank and frame

With the confirmation on new tanks on the way and not needing to return these tanks, I'm having a go with a silicone sealant. I put a small bead on the sealing surface and then installed the FEP over top so it would squeeze in place and down the side. I need to work on a smoother bead, but it looks like there are no gaps on the sealing surface itself.

Possibly of note for future cataloging, I used a $20 for 8 FEP from Amazon for this.

I'll let it sit for 24 hours and then fill it with water and see what happens.

RE: Resin Leaks between tank and frame

Filled it with water last night around 10pm. Last check before bed around 1am had the paper still dry. This morning about 10am the paper is still dry.

I want to give it at least 72 hours before I'll be willing to consider putting resin in it.

RE: Resin Leaks between tank and frame

At the 60 hour mark the paper towel under the tank is still dry. I'll take it apart tonight to confirm that water is not getting where we don't want it, see if there is any indication of reaction with the FEP, see how much of a pain it will be to clean up between FEP changes, and to try to get a new film on without getting silicon smeared where I don't want it...

Got notice from DHL that my new tanks from Prusa should be here today. Will immediately fill them with water and start testing them. I would like to believe that I just happened to get 2 bad tanks and these new ones will function properly, but I'm not holding my breath...

RE: Resin Leaks between tank and frame

At the 60 hour mark the paper towel under the tank is still dry. I'll take it apart tonight to confirm that water is not getting where we don't want it, see if there is any indication of reaction with the FEP, see how much of a pain it will be to clean up between FEP changes, and to try to get a new film on without getting silicon smeared where I don't want it...

Got notice from DHL that my new tanks from Prusa should be here today. Will immediately fill them with water and start testing them. I would like to believe that I just happened to get 2 bad tanks and these new ones will function properly, but I'm not holding my breath...

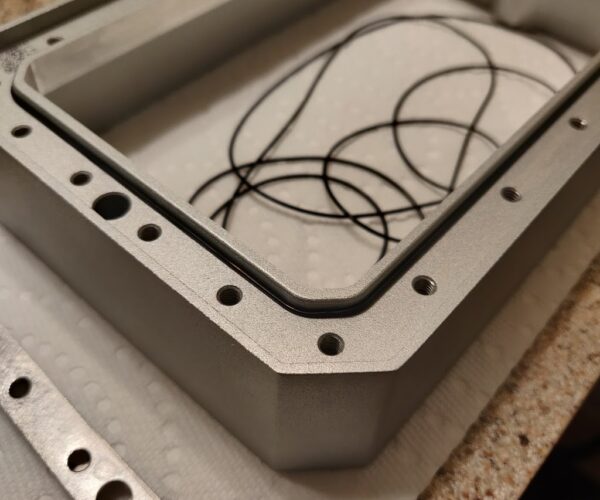

I found some o-rings on McMaster that fit the tank pretty well and will be trying those once the new Prusa FEPs arrive.

https://www.mcmaster.com/1302N101/ 100 mm ID, 1 mm Wide and they stretch just perfectly for the tank:

RE: Resin Leaks between tank and frame

@ryan-c29

That would be so much less messy than the silicone. Is the retaining place going to fit properly? My plate is flush with both sides of the trough so it looks like it would skew the plate and keep the screws from being recessed enough.

For testing purposes (rather than wasting Prusa FEPs) I used https://www.amazon.com/gp/product/B08BYKR34H. I used a pick to poke pilot holes and it went on with no issues. Actually I'm hoping that they work well for printing too as without having to deal with the laser cut disks it was much nicer to install than the pre-cut Prusa sheets. Basically just follow

RE: Resin Leaks between tank and frame

@gnat

The frame will certainly not fit flush with the current tank design. A channel for the o-ring would need to be milled into the tank for it to all fit nicely. In the meantime I changed out the screws to ones that have a thinner head to ensure they don't stick up over the tank and block installation if the seal is tight enough. FEP won't arrive for a week I expect so don't hold your breath until then heh. Over all though the o-ring approach does look super slick, plus they are cheap at $8 per 5, and only requires a small modification on Prusa's end to their tanks to ensure a 100% water tight seal if they wanted to go for a tank rev2.

RE: Resin Leaks between tank and frame

@ryan-c29

What screws did you go with? Hopefully not the $80 ultra low profile option 😆

RE: Resin Leaks between tank and frame

@gnat

...don't ask... =p

RE: Resin Leaks between tank and frame

@ryan-c29

Ouch...

Regarding the o-ring and getting the tank milled, that might be easier than trying to get the lip polished. I'm having trouble finding someone local that thinks they can do it in the required tolerance. Milling a trough for the o-ring should be easier for them to do though...

New tanks came in with FEPs pre-installed by Prusa. Can't tell for sure since the FEPs were on, but it looks to have the same texture on the lip. Tanks are doing the water test now.