Model not sticking to supports & first layer issues

I have the SL1 now for a week in use.

So far, only Benchy the benching boat was a successful print.

Around 40 hours of printing time, lots of time and resin flooded down the drain, my motivation changed into pure frustation. So far, that Im abandoning this 3D printing stuff entirely.

First layer wasn't sticking right to the build plattform most of the times, I cleaned the FEP multiple times before reinstalling the tank (around 4-6 times). Except from some scratches, there are only a few smudges on the far corners. Cleaning was done only with water and dishing-soap (and the outside of the tank with a sparse IPA weted paper towel).

The Build plate was also cleaned with dish-washing soap and IPA afterwards, around 2-3 times.

After 15hour days (no joke) of trying to get ANYTHING successful out of this thing, hours of searching around forums and other sources, I came to an end.

Im obviously too dumb to operate such things. Tank with only a bit dust on it.

Tank with only a bit dust on it.

(No pictures available from the first layer not sticking to the plattform)

Building was fun, Support is great, no complaints here.

Note:

Benchy was printed directly onto the building plattform without ANY supports.

PS

Many times when I start the first print of the day, the printer aborts the start of the print with an error about the UV light fan: not enough RPM.

When I restart the print, everything is fine. Already checked the fan and the connections. Firmware is the current one (installed on last weekend)

RE: Model not sticking to supports & first layer issues

I have the SL1 now for a week in use.

So far, only Benchy the benching boat was a successful print.

Around 40 hours of printing time, lots of time and resin flooded down the drain, my motivation changed into pure frustation. So far, that Im abandoning this 3D printing stuff entirely.

Please tell us that you are speaking metaphorically and you are not really dumping resin down the drain!

First layer wasn't sticking right to the build plattform most of the times, I cleaned the FEP multiple times before reinstalling the tank (around 4-6 times). Except from some scratches, there are only a few smudges on the far corners. Cleaning was done only with water and dishing-soap (and the outside of the tank with a sparse IPA weted paper towel).

The Build plate was also cleaned with dish-washing soap and IPA afterwards, around 2-3 times.

After 15hour days (no joke) of trying to get ANYTHING successful out of this thing, hours of searching around forums and other sources, I came to an end.

You mentioned getting a Benchy to print, can you post some pictures of it for us to analyse? Also, please post better pictures of some of your failures (both what stayed attached to the plate and what stuck to the FEP) so we can analyse them as well.

It looks like you are using the Prusa Orange resin? I would then assume you are using the profile for that resin in PrusaSlicer? Have you run a resin calibration test with the resin? If not give that a try an let us see the results (use 0.5s intervals and have the layer time from PrusaSlicer in the middle of the range). Non ideal exposure times can have a negative impact on adhesion and supports.

Are you mixing/shaking the resin well before pouring it into the tank? Or have you been letting it sit idle in the tank for long periods (days)? Improperly mixed resin can have a negative impact due to it not curing correctly.

RE: Model not sticking to supports & first layer issues

@gnat

Temperature can have an effect too, right?

RE: Model not sticking to supports & first layer issues

@gnat

Temperature can have an effect too, right?

I know temps can effect prints and that some resins are more sensitive than others, but I've never run into issues (but my printing room stays between 75-85 degrees) so I don't know what the range is or what effect it can have.

RE: Model not sticking to supports & first layer issues

Please tell us that you are speaking metaphorically and you are not really dumping resin down the drain!

You mentioned getting a Benchy to print, can you post some pictures of it for us to analyse? Also, please post better pictures of some of your failures (both what stayed attached to the plate and what stuck to the FEP) so we can analyse them as well.

It looks like you are using the Prusa Orange resin? I would then assume you are using the profile for that resin in PrusaSlicer? Have you run a resin calibration test with the resin? If not give that a try an let us see the results (use 0.5s intervals and have the layer time from PrusaSlicer in the middle of the range). Non ideal exposure times can have a negative impact on adhesion and supports.

Are you mixing/shaking the resin well before pouring it into the tank? Or have you been letting it sit idle in the tank for long periods (days)? Improperly mixed resin can have a negative impact due to it not curing correctly.

Of course I wasn't speaking literally with the resin. Just meant in the way of "wasting for nothing"-kind of way.

The settings were almost untouched by me. I haven't changed anything in the profile (and don't know what half of the settings meant to do in the expert mode. Yes: I'm THAT new to this stuff).

Resin was everytime shaked well (maybe too much, because little bubbles were visible?). The temperature test wasn't failing. Room temperature was around 17° - 20° C.

Sadly, the garbage truck just collected the stuff a moment ago. The failed prints I mean. Maybe I can find something left in my flat. Will look for one!

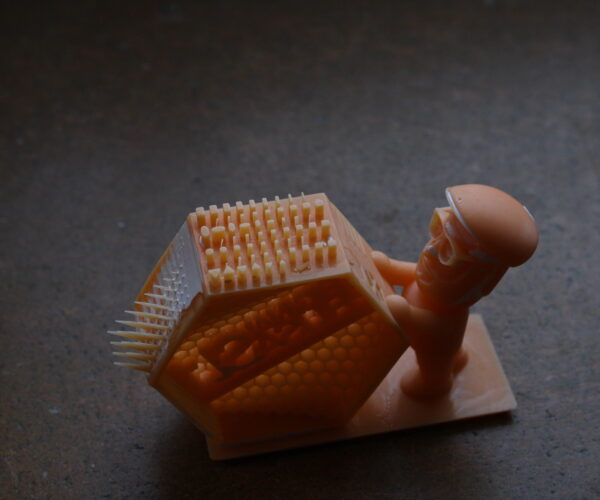

A calibration test? These are in the folder of the machine, right? I printed that Prusa figurine with the torture wheel. Some tiny parts are missing, some lines are bend. Otherwise okay.

(Edit/ Note: The white stuff on the Torture wheel figure are most likely impurifications of my cleaning IPA-glass. Most-most likely cellulose-based [i.e. paper towel] and NOT part of the print)

I think it is something with the settings. Not the machine/ profiles. Since every print with a base only was successful and none with supports. Maybe the supports are too thin, not hard enough or something.

Sadly, I cant find any pictures from stuff sticking on the foil. I was too busy cleaning it everytime, and normally I dont think, with sticky gloves, "Lets grab the camera!". The stuff on the fep was only a "puddle" resin. In the shape of the ground layer/ base before the supports.

Currently the printer is running with settings suggested by a friend. A bit higher exposure time. Maybe it is too cold for resin.

Edit 2

Forgot the requested Benchy pictures. Was printed directly onto the build-plate. Damage occured when I had to use much much more force than expected to get it off there.

RE: Model not sticking to supports & first layer issues

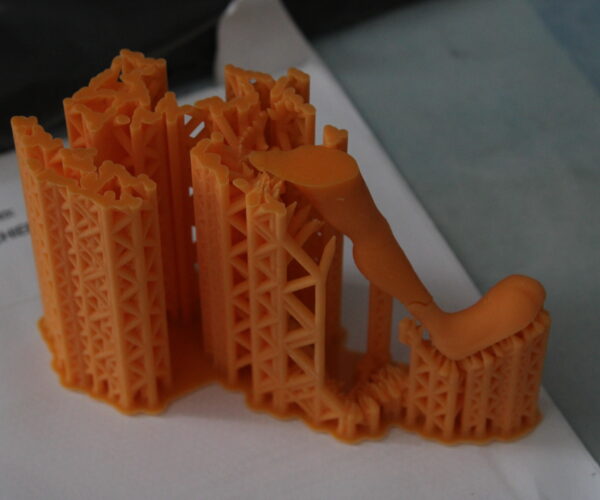

Aright, the latest print was a success!

Stuff I've changed:

-Increased pillar diameter to 2mm

-Increased support density to 150 %

-manually placed more supports on the surfaces with not enough supports (in my eyes)

-Increased exposure time for first layer up to 40 sec

-Increased exposure time for other layers to 10 sec

-changed orientation (used auto-orientation)

Only thing that is a bit bothering me now, are the little "holes" in the model, by some supports. But I will figure this out, too!

Maybe I will try and change the contact-surface diameter of them and make it smaller.

Thanks to everyone who tried to help! Much appreciated!

So this is the best "monday" print I could ever have : D

RE: Model not sticking to supports & first layer issues

Of course I wasn't speaking literally with the resin. Just meant in the way of "wasting for nothing"-kind of way.

Glad to hear. Unfortunately there are those that don't understand this, so it's always worth double checking.

The settings were almost untouched by me. I haven't changed anything in the profile (and don't know what half of the settings meant to do in the expert mode. Yes: I'm THAT new to this stuff).

Compared to looking at Chitubox for other printers, there really isn't much to tweak in PrusaSlicer for the SL1. The only things I've fiddled with are the layer times and so far so good.

Resin was everytime shaked well (maybe too much, because little bubbles were visible?). The temperature test wasn't failing. Room temperature was around 17° - 20° C.

Bubbles are OK. They should all rise to the surface and mostly pop during the "mixing" step when the print starts.

That temp is a bit chilly for me (23-27 is my comfort zone and what my print room ranges), but I don't know that it is low enough to be an issue for the resin in question.

What I see here is that it looks like it stuck to the FEP a couple of times, but managed to recover after a few layers. Interesting.

A calibration test? These are in the folder of the machine, right? I printed that Prusa figurine with the torture wheel. Some tiny parts are missing, some lines are bend. Otherwise okay.

Yes I'm referring to the built-in tests. Specifically there is a resin calibration test that can help you dial in your layer times.

Sadly, I cant find any pictures from stuff sticking on the foil. I was too busy cleaning it everytime, and normally I dont think, with sticky gloves, "Lets grab the camera!". The stuff on the fep was only a "puddle" resin. In the shape of the ground layer/ base before the supports.

Yeah it is always a pain, but when trying to get help it can really be helpful sometimes.

Currently the printer is running with settings suggested by a friend. A bit higher exposure time.

The resin calibration test can help you dial that in.

Maybe it is too cold for resin.

The Tech Sheet says it should be stored at 10-25c. They also list the viscosity at 25c, but do not list temp requirements for printing. My gut says that temp is probably not the issue, but if you have the ability you could certainly try raising the room temp a few degrees.

Forgot the requested Benchy pictures. Was printed directly onto the build-plate. Damage occured when I had to use much much more force than expected to get it off there.

That Benchy looks good and doesn't show any of the signs I was looking for in regards to there being a leveling issue. It does appear, however, that you could probably drop your initial layer time down 10-20 seconds. That will reduce the elephant's foot and should also make it a bit easier to remove from the platform. Given that your other issues, however, you probably need to lower your normal layer time a bit too (again the resin test can help determine that).

Unfortunately I have never used the resin that came with the printer and almost exclusively use Elegoo's water washable resin, so I can't offer specific time suggestions.

RE: Model not sticking to supports & first layer issues

Aright, the latest print was a success!

Stuff I've changed:

-Increased pillar diameter to 2mm

-Increased support density to 150 %

-manually placed more supports on the surfaces with not enough supports (in my eyes)

-Increased exposure time for first layer up to 40 sec

-Increased exposure time for other layers to 10 sec

-changed orientation (used auto-orientation)

How big is that model? It doesn't look big enough to need supports that dense or that thick. Using 2mm supports as a guide, that model looks like the default supports with 75-100% density should work.

Contrary to my prior comment about your Benchy, 40s is about what I would expect for the initial layers. 10s for the rest seems really high. What layer height are you using? For my Elegoo resin I use 6.5s at 0.025 layers and 7.5s for 0.05 layers. The layer time being too high can definitely be a factor in the issues you have been having.

Only thing that is a bit bothering me now, are the little "holes" in the model, by some supports. But I will figure this out, too!

Maybe I will try and change the contact-surface diameter of them and make it smaller.

The things that have greatly helped this for me are:

- Using fewer/better/different placed supports. This will take some practice and experience. Things like sometimes the auto supports will under support some objects where there are clearly not enough supports for the weight, large unsupported areas that allow for instability in the part, etc...

- I never use the auto orientation anymore. It was useful in the beginning, but as I learned to think about the supports better I started finding that it rarely provided me the best orientation.

- I dropped my initial layer time from 50s to 35s.

- I dropped my layer time from 8s to 6.5s for 0.025 layers (what I almost always print).

- Submerge the platform in the CW1 tank with 99% alcohol for a 10 minute wash.

- Remove the objects with their supports from the platform and submerge them in warm (90-100f) and start cleaning with a toothbrush.

- Gently squeeze off the supports while the part is in the water and finish cleaning.

Now I find that I have far less post processing required to cleanup from the supports.

RE: Model not sticking to supports & first layer issues

Well, I wasn't able to replicate the success from the last time. The printer is now running for around a whole day (several printing attempts) and still the same issue: Layers not sticking to supports.

But it doesn't matter anymore. I will abandon the whole 3D printing world and creative hobbies in general.

Too much of a hassle with way too high costs (money and time) just for nothing.

My frustration is in the "im really aggressive angry now"-realm over my sheer incompetence

@gnat:

The model of the pokemon measures 7cm in hight. I havent hollowed it, so it has some weight (i guess).

Last time I hollowed it, I created a suction cup (proof of my dumbness). An attempt with this size and the normal setting for supports lead to a model sticking to the foil and the support to the building plate.

The settings were at "normal", so Layer is 0,05 or something? The detail options are costing me way too much time just to figuring out, that it is another failure. So im not touching that ever again.

Thanks for the suggestion. I will leave this place now.

Bye all.

-The too dumb to print guy

RE: Model not sticking to supports & first layer issues

But it doesn't matter anymore. I will abandon the whole 3D printing world and creative hobbies in general.

Don't be hasty about it. It is definitely a learning experience, but it gets much better once you are there. I don't know the resale market where you are, but for me I ended up sticking with the SL1 because I couldn't stomach the obscene loss I'd have to take to sell it on. My advice would be to just clean everything up and put it aside for awhile until you can find a better head space to try again.

Too much of a hassle with way too high costs (money and time) just for nothing.

My frustration is in the "im really aggressive angry now"-realm over my sheer incompetence

My story is one of a string of hardware issues and incompetent Prusa support and it soured me on the whole thing. I'd be willing to loose some money on it, but $1000USD of a loss is too much for me. So I've kept it and now that the hardware issues appear to be behind me it is actually a good printer, but my feelings towards it mean that I rarely print with it. My MK3S is kinda similar as well. When I first got it I ran it almost constantly, but when I first (failed to) installed the MMU2S I ended up just walking away and not touching the printer for 3 months. Now I still use it when I find the need, but like with my SL1 there is a "do I really want to bother?" hurdle I have to overcome. My MK3 has been idle since last weekend and it's been a month or so since I used the SL1.

So I get it. My advice is to just not be too hasty.

@gnat:

The model of the pokemon measures 7cm in hight. I havent hollowed it, so it has some weight (i guess).

Ahh. Then yes the larger supports will likely be needed in that situation.

Last time I hollowed it, I created a suction cup (proof of my dumbness). An attempt with this size and the normal setting for supports lead to a model sticking to the foil and the support to the building plate.

You are too hard on yourself here. It is a new thing and you are learning. I personally haven't bothered with hollowing anything as I don't want to deal with vent holes and getting the inside clean and cured. It helps that Elegoo's resin is pretty cheap in the US so weight is my main concern rather than cost (compared to my friend with his Form3 and it's disgustingly expensive resin).

The settings were at "normal", so Layer is 0,05 or something? The detail options are costing me way too much time just to figuring out, that it is another failure. So im not touching that ever again.

I get your frustration, by all means take a break and try not to think about it for awhile.

When/if you do come back to it, try that resin calibration print and I'd start it at 7 seconds with 0.5s intervals for the 0.05 test.

The object of the layer time is to find that sweet spot where it is cured just enough to produce the desired detail, but not long enough to create too much adhesion on the FEP. Even using the resin calibration that still took some time to dial in with the Elegoo resin I use. I would hope that Prusa's profile for their resin would already be close, but there could be variation for your specific machine (I noticed I had to adjust my Elegoo profile after I had to replace my LCD). One of the few nice things I have to say about the SL1 is in regards to their inclusion of the resin calibration test. Most (all?) the other printers require you to do separate prints for each layer time you want to test, but Prusa's option lets you test 8 exposures at the same time. That can save a lot of time and hassle.

RE: Model not sticking to supports & first layer issues

Last post by me.

Documenting further proof of my two week failure journey without any improvement or learning ability.

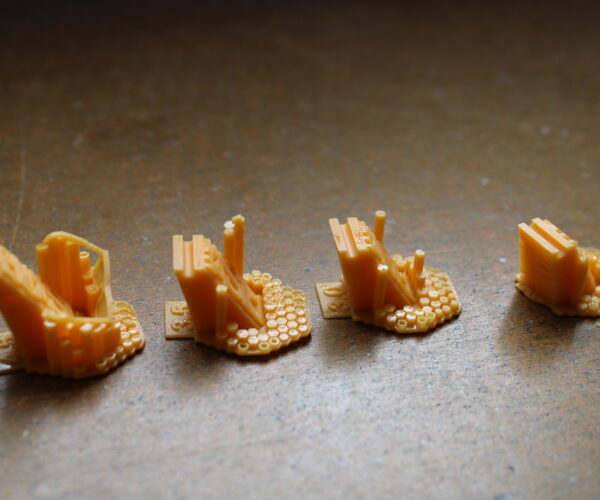

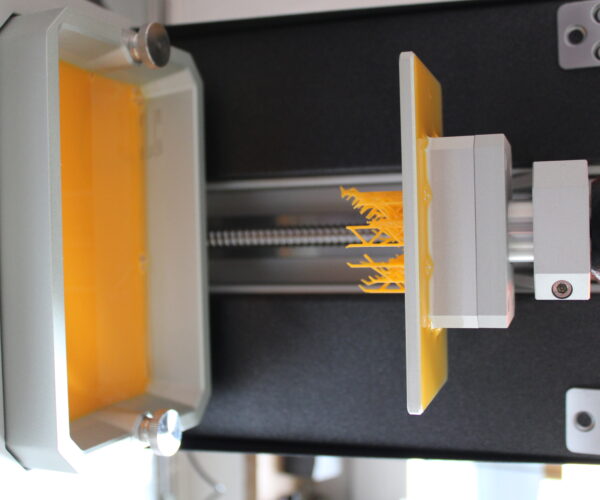

Calibration 0,025 or whatever thingys, stuff sticking to foil (disassembled because everything goes back into its cardboard box and out of my posession), a bit of the junk which I produced, the only stuff that was coming out of the two weeks (not shown are the 4 full trashbags and soapy water to clean the foil),

Some attept of a model, strangely only with one leg not the other one (aborted and thrown into trash by now. Again of course).

With this. Im gone now.

Maybe this will help some one else.

Im overly frustated by it and cant take it any longer with this.

I sank way too many hours into this thing. Some days even from 5 o'clock am until 9 o'clock pm.

With now results other than shown.

Good bye and have a nice day.

RE: Model not sticking to supports & first layer issues

Whoa. Those times are way too low. Honestly I'm surprised that they printed as well as they did and that the 4.5s test appears to be mostly correct is impressive to me. For a 0.025 test I would have started no lower than 6 seconds as the bottom value for the initial test.

RE: Model not sticking to supports & first layer issues

Your prints are failing at the point where the supports meet your model, which suggests that you need to increase the diameter of the Support head

As each layer prints it sticks to both the print bed and the FEP. The tank then tilts to progressively tear them apart. Ideally the print tears away from the FEP and repeats. If instead it tears away from the print bed then all subsequent layers will stick to the FEP and you end up with a puddle at the bottom. I’ve found that the FEP doesn’t need to be too clean. It still works if fragments of resin are still on the FEP, so long as the print bed can come within 0.05mm of the FEP. Also, the FEP may be pitted and still work. Its not until the FEP leaks that it needs to be replaced

The print bed must be clean. Scrape it off and wipe it with a paper towel before putting it back into the printer

If the print won’t stick to the print bed then I apply a layer of Monocure3d Platebond to the build plate. I then use tack hammer and paint scraper to hammer the print off the build plate

I print at temperatures as low as 00C. At lower temperatures resins become more viscous (less runny). Resins can be stored and used at temperatures above whatever temperature they begin to crystalise at, because that changes the properties of the resin. In the case of the resin I use; Monocure 3D flex, that is about -50C

I rarely use supports on my prints, as supports are an extra thing to go wrong and I usually have a flat side I want to print out perfect without having to sand. Sometimes, I model supports @ 1.5mm diameter since PrusaSlicer won’t add supports without having them below the model

I’m not happy with Prusa resin, which is why I use the resin above. Its more reliable