Re: Wallet Style Filament Slack Take Up

Ted: Try the sealed tupperware containers, they work pretty good. My biggest problem is that they hold 4 spools not 5, so I end up needing two containers.

I really liked having a shelf above for spools and one below for the printer and work space. I'll probably move things back soon.

I'm finding the length of the pre-wallet tubes critical, it is easy to have an extra few inches which puts in a couple bends and adds a lot of drag.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Wallet Style Filament Slack Take Up

Thanks abraham.m and thanks for your suggestions. I put one up on thingiverse. https://www.thingiverse.com/thing:3303876

and added a video

ted.t5, is the auto-rewind working for you? I tried another and abandoned it. Couldn't get it to work properly. Probably because I am PTFE leading up to the wallet. I'm working in a basement and need to deal with moisture.

Chuck, I like your setup. Did you use new tubing or is the the original from PRUSA? I find the tubes I have are very tight even for PRUSAMENT and think this is part of my problem.

Re: Wallet Style Filament Slack Take Up

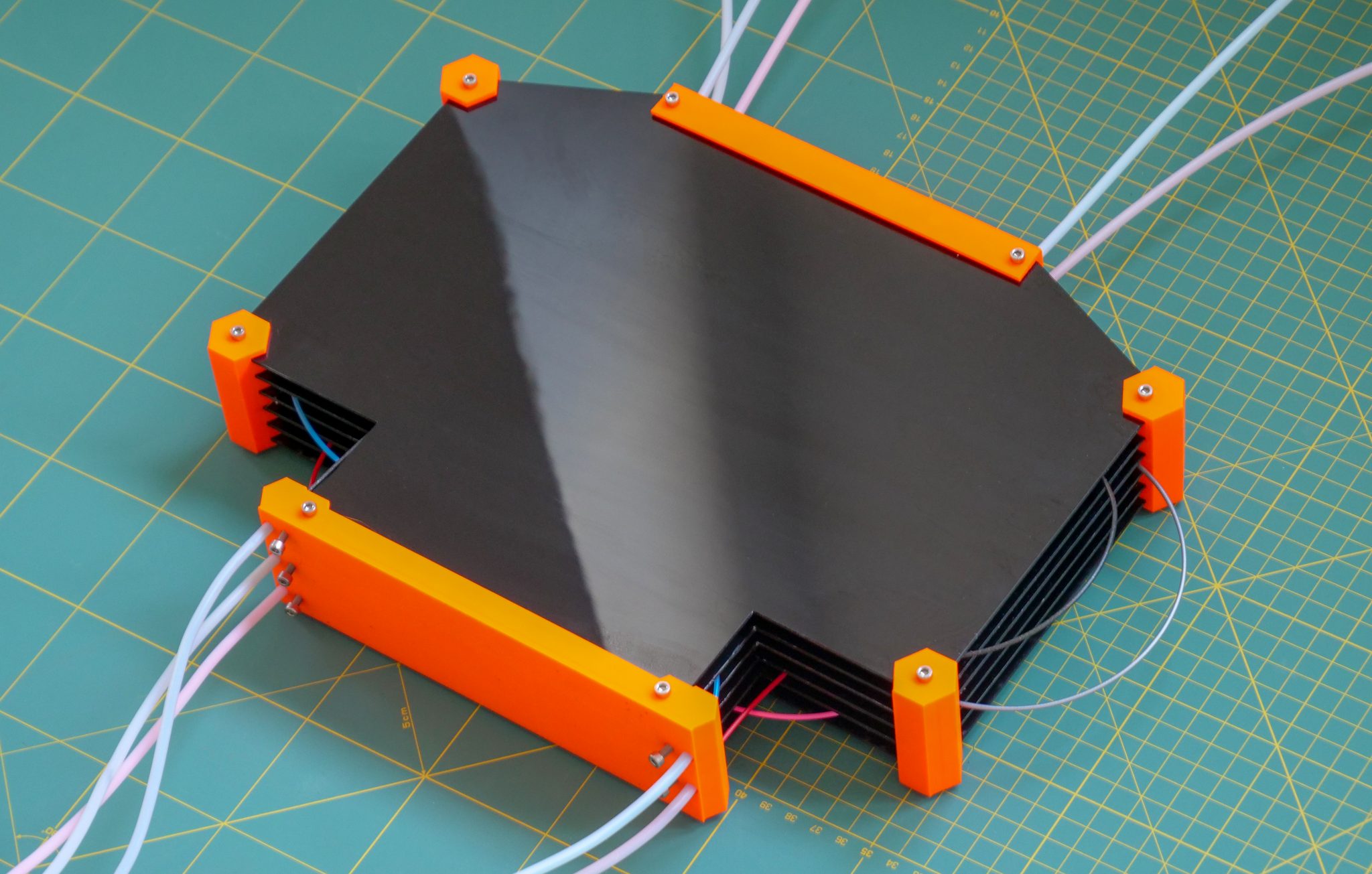

So, the whole idea of having a thread of community learned answers was to help Prusa avoid further mistakes in their next generation of Slack Buffer.

I feel they missed the lesson of allowing the lines to come in and out of the device while still in their PTFE tubes.

It seems like the missing corners are there to help you get the filament through, but it's not as easy as a slit.

I'm a little concerned about the sides being printed instead of cut from something smooth, but in practice I would rarely expect that to be an issue.

They make it seem, horizontal, so I would be curious to see this working on anything flexible. My own design is somewhat sensitive to the angle the PTFE comes out at. I would like to play with this one.

In short - has anyone used this? I have a couple reasons (quite possibly unfounded) for concern, and I would like to hear/see how it works in practice.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Wallet Style Filament Slack Take Up

I feel they missed the lesson of allowing the lines to come in and out of the device while still in their PTFE tubes.

Correct me if I'm wrong, but it looks from the photo like the filament is inside the PTFE tube as it enters and exits the buffer.

You can see that the white PTFE tubes are attached to the buffer, and the bits of filament visible inside the buffer are thinner and different colors.

My big question is how annoying will it be to load the filament through the buffer, but that was my concern with all the wallet-style designs so far.

Re: Wallet Style Filament Slack Take Up

Loading five filaments through a buffer is a royal PITA. My design has a removable exit piece with the ptfe tubes attached so all 5 loose ends fed through the buffer can be easily inserted into the exit tubes, then the exit piece is reattached to the buffer. Nonetheless it is still a pain.

Interested to see how the Prusa version works.

Re: Wallet Style Filament Slack Take Up

That’s why my buffers are quite elaborate. Makes loading very easy.

Re: Wallet Style Filament Slack Take Up

Loading five filaments through a buffer is a royal PITA. My design has a removable exit piece with the ptfe tubes attached so all 5 loose ends fed through the buffer can be easily inserted into the exit tubes, then the exit piece is reattached to the buffer. Nonetheless it is still a pain.

Interested to see how the Prusa version works.

It's a big pain tbh. The filament is very hard to catch on the other side of the buffer as the incoming tube is angled, and once caught there is too little room to feed the filament into the long PTFE tubes towards the MMU2 unit.

Wish they went for a detachable tube to allow feeding a large chunk of filament at once.

Re: Wallet Style Filament Slack Take Up

Yeah, in my original design, that's what I went with - slotted holders such that you could load the PTFE then thread it into the buffer. It's likely not hard to tweak the end pieces. You then end up with the trouble of holding the PTFE solidly, but it's a reasonable problem.

I've been using the rewinders lately. So far all my testing has indicated that the buffer method is relatively unimportant, but the approach angle of the PTFE's into the back of the MMU is the source of most problems

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Wallet Style Filament Slack Take Up

It's a big pain tbh. The filament is very hard to catch on the other side of the buffer as the incoming tube is angled, and once caught there is too little room to feed the filament into the long PTFE tubes towards the MMU2 unit.

Wish they went for a detachable tube to allow feeding a large chunk of filament at once.

I have to wholeheartedly agree. It took me about 10 minutes the first time to get the filament through. You have to get it trough the first tube with its bend in the right direction to even come out at the correct side first. I mean, it obviously works during printing, but the loading is really cumbersome.

Plus I wish they designed it with some festo fittings on the printers' end. I often take the printer with me and getting it torn down and set up just became even more of a nuisance.

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Wallet Style Filament Slack Take Up

I guess one could print PTFE retainers which allow you to pull the tube out - I've done stuff which would work.. But it's annoying that it's that hard to use out of the box.

Someone will make an spool auto-rewinder that uses a metal spring and then we'll be done with all this. 🙂 At the end of the day, I think the biggest limitation is that angle the PTFE enters the MMU, and anything behind that (assuming it doesn't tangle, etc) just needs to be easy to use. 🙂

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.