IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

Maybe its because I'm in the USA and have a bias against ever being stuck inside the IKEA mouse maze... but what is the IKEA Lack obsession?

There's 7+ years of designs of gluing and screwing custom sized acrylic/plexi enclosures with brackets and such on many of the social 3d printing sites. They all seem fairly strong in design, use substantially less plastic in brackets, and are much cheaper overall for those looking for budget DIY. Acrylic is easy to cut, glue and drill.. and even edge polish if you want to put time into it.

If I was going for a showpiece enclosure, I'd be looking for a laser cut polished acrylic with or without extruded aluminum framing, knowing that the additional cost is for the look. Adding in a paper IKEA structure into the space doesn't scream quality, and may just add a combustible material to a device designed to be an oven.

Is this just an IKEA fan thing, or is there value that I'm missing?

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

Maybe its because I'm in the USA and have a bias against ever being stuck inside the IKEA mouse maze... but what is the IKEA Lack obsession?

I think it's mostly driven by cost. It's hard to beat a $10 table as a starting point. A lot of people want a decent looking solution at minimal cost, and the Lack enclosures meet that need.

There's 7+ years of designs of gluing and screwing custom sized acrylic/plexi enclosures with brackets and such on many of the social 3d printing sites. They all seem fairly strong in design, use substantially less plastic in brackets, and are much cheaper overall for those looking for budget DIY. Acrylic is easy to cut, glue and drill.. and even edge polish if you want to put time into it.

That's probably true with most things, but particularly for furniture. I've looked around for a commercial cabinet solution that meets my needs, but am finding them costing closer to $1,000 than $10. My dad knew enough carpentry that I know he could have cranked out a gorgeous rack at low cost in no time. I wish I'd thought to ask him to do so when I had a rack of network gear at home. Lack of tool and space are barriers for a lot of folks.

If I was going for a showpiece enclosure, I'd be looking for a laser cut polished acrylic with or without extruded aluminum framing, knowing that the additional cost is for the look. Adding in a paper IKEA structure into the space doesn't scream quality, and may just add a combustible material to a device designed to be an oven.

The Lack enclosures are a bit like rock soup. You start with a $10 table. Then you add the cost, time, and effort of adding 3D printed parts. Then you add acrylic doors. Then you add reinforcements for stability. Then you add a paver for sound reduction. Then you add a fan for cooling. You go broke saving money.

Is this just an IKEA fan thing, or is there value that I'm missing?

If nothing else, you get to say "I 3D printed some parts and made this awesome enclosure for $10" with a straight face.

All that said, if I could fit my Sidewinder into one, I'd be tempted as a quick solution.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

Stone soup... So correct! I appreciate the honest response. Here each Lack table is about $15... so $30 for two.. and the acrylic is the money. I'm going to throw out the stone 😋. Printing multiple days of plastic to wrangle the wood, naw.... plenty of opportunity to print functional plastic to accessorize and stabilize an acrylic cube. Will see how it turns out and will share if I don't embarrass myself!

Happy new year.

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

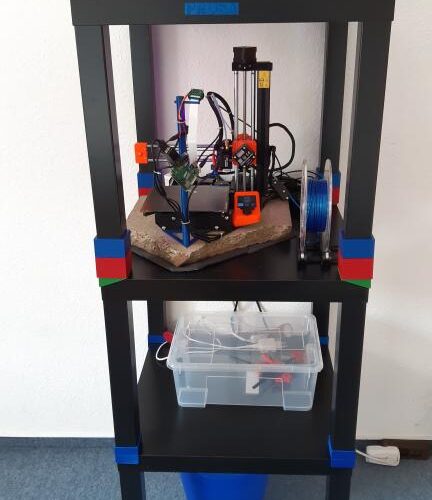

I get your criticism regarding the LACK table. I was turned away by it being basically compressed paper as well. My solution? Spend even more money at IKEA for a BROR, printing even more stuff to make it happen:

On the upside, I do think that while it certainly isn't very compact it does look like decent quality and I can say "I designed my own enclosure" 😉

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

@thejiral

Interesting design. This is similar to what I plan to build but out of wood.

--------------------

Chuck H

3D Printer Review Blog

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

There are also relatively inexpensive modular systems (DIY kits), also, like Prusa, produced in the Czech Republic:

https://www.tukkari.com/prusa-mini-enclosures

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

@thejiral

I do like that much better than the lack. They are all still too short for a guy that's 186cm tall (6'1"+).

@karl-herbert

Those are reasonably priced laser cut acrylic DIY cases that look good... Gotta love the shine of those thermally cut edges.... until the IPA hits them and they craze. 😱

I've purchased two sheets of 3mm polycarbonate and will build something custom on top of one of my workbenches. My printer is in my tinker workshop (man cave/hide) and doesn't need to emulate furniture. I was just amazed that when I was looking for other's designs for a DIY enclosure, I had to look back several years before the Lack obsession to find anything that wasn't IKEA paper based!

I'm not really anti-IKEA... my kids hamster lives in an IKEA Detolf... I just didn't understand why everyone was 120cm (4') tall and thought that putting a 400C heater in a paper based enclosure was a good idea. lol.

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

@christopher72

Height is not an issue with BROR shelfs though. 😉 That is the lower shelf because I prefer it that way but there is also ~2 m BROR shelf available which one could use as the base for this enclosure, without even changing anything in the design, other than mounting everything higher up.

The acrylic cases from tukkari look nice. For an MK3 and a Mini they'd be really interesting. The price is very fair as well, given that the material costs of that acrylic glass itself are easily half that price alone. However, for the MMU case I am not so sure I would want one of those. It is very helpful to have unobstructed access from the top without much hassle or the need to remove the printer from the enclosure. As far as I can see that, this is not given with their MMU enclosure. But I suppose that is a rather specific requirement.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

@thejiral

True - I'm considering using magnets to secure a top panel, and front as well. pretty doors are nice for a living space, but its either going to be running pla/petg and open, or closed and doing nylon/pc. Right now I can't interrupt to build, since my boys are printing 3dsets.com 1/10 RC trucks. I need more printers.

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

@christopher72

Magnets are the way to go! I have done this on my enclosures.

--------------------

Chuck H

3D Printer Review Blog

Saw your post about MK3S/MMU enclosure, and couldn't miss the OSU logo. I'm also an OSU grad, and am thinking seriously about adding the MMU2 to my Prusa MK3S printer. I would be very interested in what you come up with for your enclosure, especially if you are still in the Columbus area (I live in Grove City). If it helps, you can contact me at [email protected] or [email protected]

Frank

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

The Lack enclosures are a bit like rock soup. You start with a $10 table. Then you add the cost, time, and effort of adding 3D printed parts. Then you add acrylic doors. Then you add reinforcements for stability. Then you add a paver for sound reduction. Then you add a fan for cooling. You go broke saving money

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

"You go broke saving money"

I think this a great summation of the Lack enclosure. I also can't really wrap my mind around the design constraint of the worlds cheapest (meaning *quality* & price) table. I think that there was/ is a need to have a common starting point for people to collaborate around - and most people probably can't bang out a plywood cube to then customize. I also think it's now a 'right of passage' exercise for people coming into printing.

For me, who is new to printing, but not machining or carpentry - I want to do some of the major milestone projects others have done so I can be part of the community. Also, knowing that I want to help 'build a better enclosure,' I think there is value in an anthropological study of what's been done before.

--

All of that said, I can't get over how shitty the Lack table is and all of the very problematic issues that creates. Virtually none of the current 'Lack Enclosures' solve or even address these issues:

1- Legs are secured in only one direction - there is no connection *tightening* them to the reference face of the table.

1b - lateral support is minimal at best

2 - poly carb/ acrylic panels are smaller than the gap then enclose because of how they are joined to the frame. If they stood outside the table, they could be removable, fully seal the enclosure etc...

3 - hinges wear over time and the doors (hinges) are not removable without disassembling the table. Hinges could be lift off if they were just proud of the frame. There could also be a design so they auto close and stay open by slanting the hinge joint.

4 - the table is now too short for the MMU addon - the printing of filler parts makes the whole enclosure (v2) take over 130 hours to print from scratch. Ouch.

5 - no guides for drilling, no core design has an included way to micro adjust center parts and then tighten down. Some remixes address this issue, but not the main v1 and v2 builds highlighted by Prusa.

6 - internal corners have no relief for the mating surface (again, consistent failure to meet fundamental design basics).

6*** my personal favorite (to hate on)

WHY DOES NO ONE KNOW WHAT TYPE OF SCREW TO USE?! 3d engineering a part too small to take the proper fastener, or at least allowing for the proper fastener is beyond me. I can't stand seeing all these drywall screws with countersunk heads being rammed into these holes. At least design a female recess and offer bushings to accommodate different fasteners/ shank and head design.

--

Ultimately, I think the current designs fail to offer a fun and worthwhile level of complexity - instead they are just patchwork solutions to problems that should be avoided. When a car is hard to work on, the benefit should be that it's beautiful or well performing. The latest design highlighted by Prusa tries to engage the remix culture of the original, but in doing so dooms itself to all of the failings of the design without addressing any solutions.

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

I have 17 of these Enclosures. I have two commercial made enclosures. It is probably worth it to make your own out of lack tables. If you only need one it’s probably not a big deal. But if you were making a bunch, he will save significant amount of cash.

--------------------

Chuck H

3D Printer Review Blog

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

<rofl>. Hitting the nail on the head (no nails in any LACK, though 🙂 )

All of that said, I can't get over how shitty the Lack table is and all of the very problematic issues that creates.

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE:

I started with 1 Ikea lack table above MINI+ on desk, and ended with 3 lack tables.

I never wanted closed enclosure, because it is in separate room and therefore sound (reduced by gym mat below heavy concrete below MINI+) is no issue.

So the solution is easy 3 tables "no glue, now screw" build and cheap:

https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/octopi-holder-for-prusa-mini/#post-602266

RE:

Yes, as cheap, no enclosure option, the Lack might be not so crazy. If one doesn't mind its quality and instability.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

If one doesn't mind its quality and instability.

Each table does not need to carry much, so from outside view there is no quality problem.

With the 3D printed screwless Ikea Lack leg extensions there is no instability.

I once moved the top table 10cm to the side and the bottom two tables moved with it.

Then I removed my hand, and the whole construction moved back into normal position after some rolling.

There was no risk that anything would break or fall apart during rolling.

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

^^ By instability I was not having in mind the collapse of the table but how it handles vibrations and momentums. Sure, a lot of people use Lack tables so they obviously to work somewhat but there are more stable solutions out there.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: IKEA obsessing? Isn't a glued/screwed acrylic using less plastic and paper?

^^ By instability I was not having in mind the collapse of the table but how it handles vibrations and momentums.

I am new to 3Dprinting, starting last December. But I learned on the forum how to deal with that.

If you look at the photo you will see big concrete below MINI+ and above gym mat.

Both together reduced noise level, and improved print quality.