Yet another PVA thread

I checked the other PVA related threads I could find, but I didn't see much for answers or problems quite like what I just ran into.

I am trying to print with Inland PLA (tool 1) and SainSmart PVA (tool 2) on my MK3S (Bondtech extruder and straight through e3d heat break).

I just received the PVA yesterday and had it in my dehydrator at 120 degrees for 21 hours prior to attempting the print. I left it in the running dehydrator until everything else was setup and the printer was pre-heated so all I had to do was load the PVA and start the print.

As usual the PLA's first layer was as close to perfect as I care to get. I watched the first tool change and the start of it laying down the first PVA layer and all looked good. I checked on it again as it was starting to change back to PLA for the second layer and I had a mess on my hands and had to kill the print.

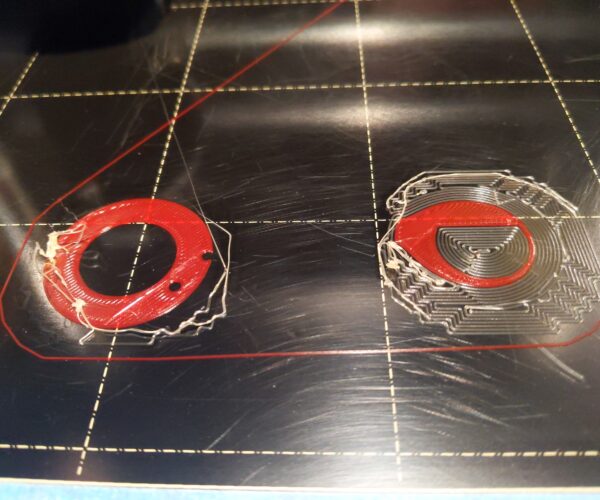

The PVA stuck around the first part, but didn't stick at all around the second part. Even around part of the first part it clearly wasn't sticking well and was partially pulled up by the mini-spaghetti monster. When I went to clean off the plate I found that the PVA that was still on the plate just brushed off and had the look of a not-remotely-negative-enough Live Z.

Anyone have any ideas how to get the PVA to stick without impacting my PLA performance negatively?

RE: Yet another PVA thread

Gave the plate a good cleaning, had the PVA back in the dehydrator for another hour, and tried again.

Other than not getting as far because I was watching for it to mess up, this is what the first attempt looked like too.

RE: Yet another PVA thread

So... Progress...

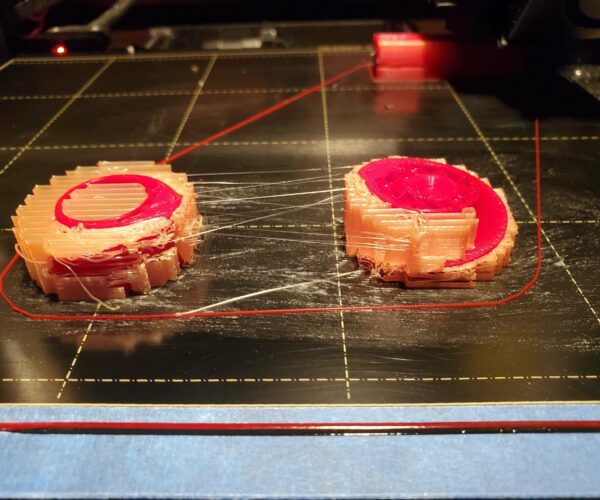

At a loss for anything else, I desecrated my plate by attacking it with a glue stick and it was able to get beyond the first layer:

Filament changes would work well for awhile, but then start giving me problems (almost always going from the PVA to the PLA).

After the last change failure last night I left the printer paused overnight and threw the PVA back in the dehydrator until this morning. It did a couple layers after resuming, but then something sounds messed up in the extruder and I went ahead and killed the print.

Some things I see here that will hopefully help in the future:

- The wipe tower looks terrible and on par with one I did while I was unaware of an under extrusion issue.

- There is a lot of bleed of the PLA into the PVA.

So I need to create a simpler test object and I think I want to play with the following items to see if it improves things:

- Slow down the print speed when on the PVA. I'm thinking somewhere between 25-50%.

- Reduce the volumetric flow as it just feels like it is working faster than the filament is flowing.

- Increase the purge volumes going to/from the PVA.

RE: Yet another PVA thread

I would suggest to get to learn your PVA filament first before doing MMU prints. Try to print some small objects with PVA only. Look how it prints, flows/sticks. Live adjust speed, flow rate if something is not printing right. Check how it prints in the whole temp range (temp tower?). Find the right settings first.

In MMU mode you definitely need to increase the purge volume (double or even tripple the default values). I've seen it in my PLA/PETG prints. You don't want to mix this materials at all costs. Consider using the script if our temp difference between PLA/PVA is higher then 10C.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Yet another PVA thread

Yeah I did consider your script as a possibility. The default settings in PS currently has the PLA at 205 and PVA at 195, so its at the far end of your range. It's definitely something I'll play with.

I hadn't considered it since it is specifically meant to be a support material, but I like your idea of printing an object just in PVA to help dial it in.

There is definitely mixing on the PLA side going on in the above print. I haven't dunked them in water yet as most of the PVA just wiped off easily, but the surface quality is what I would consider terrible compared to what I know the printer can produce. Comparing it to a pure PLA print of the same object really shows the difference in quality.

RE: Yet another PVA thread

For people returning to this topic in the future, I did a bunch of tests with using PLA & PETG in same print and found that using different materials has a huge impact on model strength. For a typical purge volume of 250mm³ you can expect layer adhesion strength to be 1/5 of what it should be. Sadly only way to get around this is to purge crazy amounts of plastic ~2500mm³, or getting a 3D printer with at least two hotends

www.antalife.com