Slicing problems - Parts of Print Missing

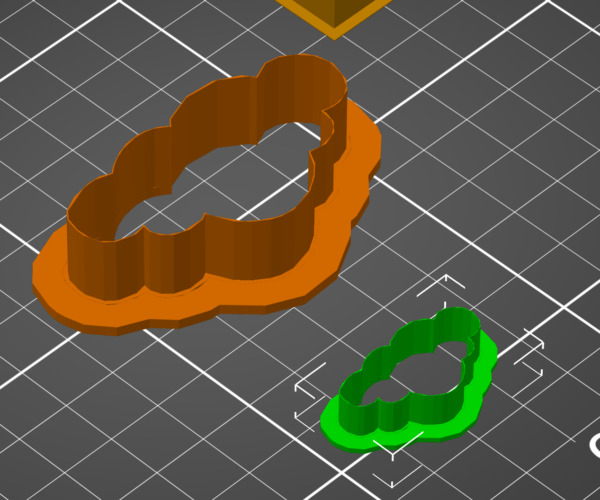

Hi, I'm new to 3D printing and am trying to print a clay cutter. The design itself is a solid shape but when I slice it, it breaks up as per the picture and that is how it prints. If someone could help me with what I'm doimg wrong I'd really appreciate it? I'm using PLA.

RE: Slicing problems - Parts of Print Missing

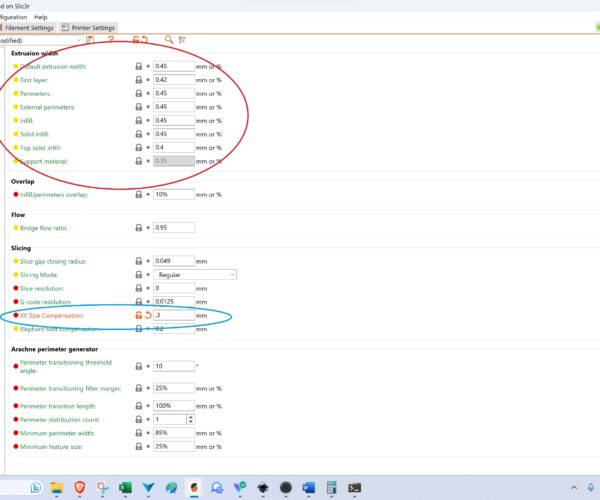

extrusion width wider than wall thickness?

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Slicing problems - Parts of Print Missing

Step 1: Find the right sub-forum.

Step 2: Give more information. You did not even tell what printer you use... Easiest way to do that is to save the project in Slicer, zip the resulting .3mf file and attache it to your post.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Slicing problems - Parts of Print Missing

Hi,

Sorry this is my first time posting and asking for help. I have an MK3s+ with an MMU2 (hence why I put it in this forum even though it's a single colour print).

I didn't realise that zip files could be accepted, I'd tried to put the file on yesterday but it wouldn't attach. Here it is: Cloud Test.stl

I'm using 1.75 PLA with the standard nozzle that came with the printer.

Thanks.

RE: Slicing problems - Parts of Print Missing

Thanks for your reply - how do I check this? It's a 1mm wall with 1.75 PLA and the out of the box nozzle. (MK3s+ with MMU2 in an enclosure)

RE: Slicing problems - Parts of Print Missing

Hi Catherine,

thank you for attaching the STL

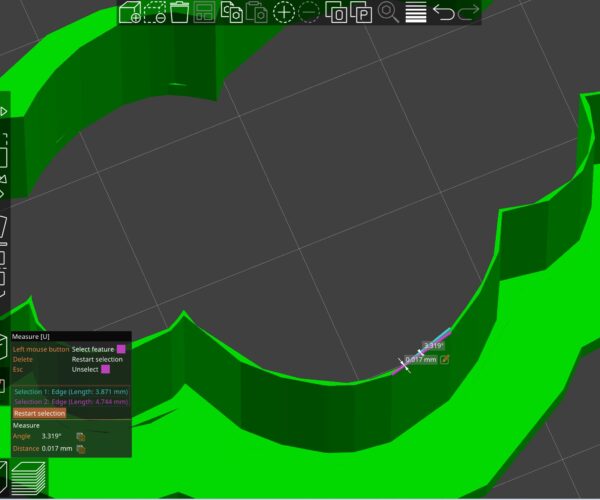

Looking at the STL, the blace of the cutter is probably not as wide as you think.

prusa shows it to be 0.17mm thick at the point that I measured. and looking at the walls, they are an inconsistent thickness which will lead to issues.

Did you make this model as a larger model and shrink / scale reduce it's size by any chance?

the default nozzle on a Mk3 is 0.4mm diameter and the default extrusion width is typically 0.45mm

any parts of your model which are thinner than 0.45mm will not be resolved by the slicer, which gives the issue that you are seeing,

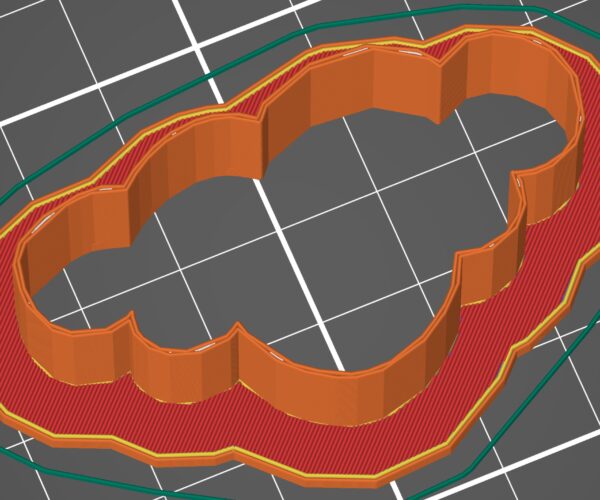

In the image above you can see the extrusion width setting inside the red oval, and I have 'Fudged ' the model by adding an XY Compensation value of 0.3mm which effectively thickens up the Small features in the X and Y axis.

BUT, the varying wall thickness of your original model then translates into variable cutter thickness, which is not brilliant.

Please be awre that printing PLA in an enclosure can also be problematic. if you start getting blockages, you may need to print with the enclosure door open.

I have attached a copy of the .3mf file that I have modified. for you to try.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK