Printing ASA with BVOH soluble support material

Prusament ASA prints with a nozzle temperature of 260 degrees Celcius while Verbatim BVOH prints with a nozzle temperature of 210-230 degrees Celcius.

Hypothesis:

1: If the printer is printing with ASA and the nozzle temperature lowers from 260 degrees Celsius to 230 degrees Celsius before the nozzle has been purged of the remaining ASA during the retraction of the ASA filament and loading of the BVOH filament, and all of the remaining ASA and newly introduced BVOH in the extruder is able to be purged and stick to the wipe tower at a lower temperature than is required for printing ASA, then the print can be successful.

2: If the printer is printing with BVOH and the nozzle temperature increases from 230 degrees Celsius to 260 degrees Celsius before the nozzle has been purged of the remaining BVOH during the retraction of the BVOH filament and loading of the ASA filament, and all of the remaining BVOH and newly introduced ASA in the extruder is able to be purged and stick to the wipe tower at a higher temperature than is required for printing BVOH, then the print can be successful.

3: If the bed temperature for both filaments is set to the recommended temperature for the ASA, then the bed temperature will not fluctuate and cause warping.

Evidence:

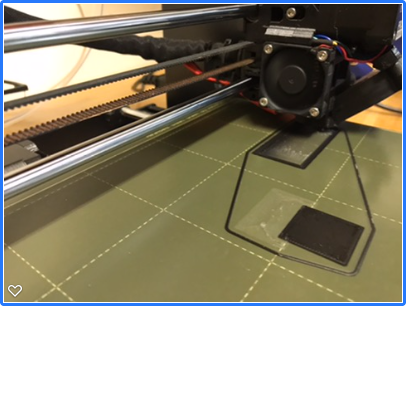

The first layer of the print displays a smooth transition on the wipe tower between the remaining ASA and newly introduced BVOH in the extruder. This means that the remaining filament upon changing from ASA to BVOH is able to be purged and stick to the smooth metal print sheet at with a nozzle temperature of 230 degrees Celsius.

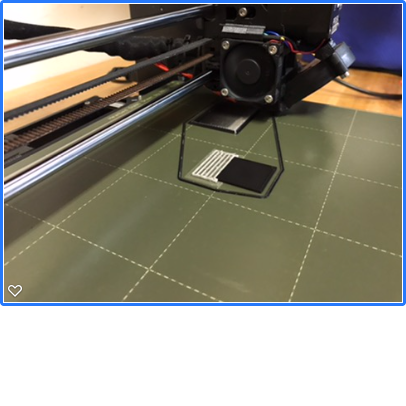

I chose full soluble supports for the purpose of seeing as many tool changes as possible is as little amount of time as possible. After a few layers of printing it became apparent that the tool changes were able to successfully purge the previously used filament (ASA of BVOH) and start clean with the next filament (BVOH of ASA).

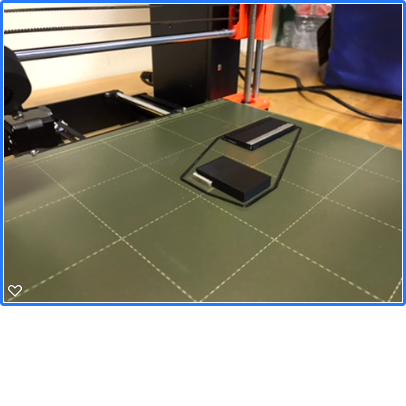

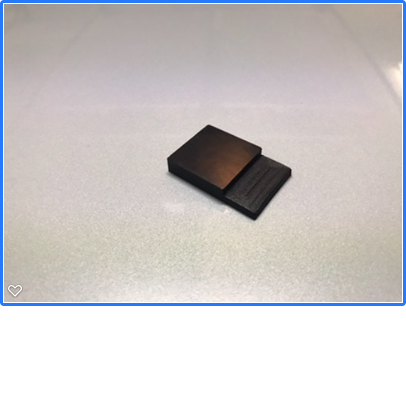

Upon completion of the print no flaws were apparent other than the need to increase the purge volume in PrusaSlicer in order to remove a few residual black specs of ASA visible in the BVOH.

Conclusion:

The MMU2S is able to print ASA with BVOH as soluble support material. With a few tweaks of the bed temperature, nozzle temperature, and purge volumes, a successful test piece was printed before attempting a larger print job I have planned for the future.

Additional Notes:

1: The piece could have been printed upside down and it would not have needed any supports, but this piece was designed for this experiment only.

2: No enclosure was used which might be necessary while printing larger pieces (more experimentation is needed)