Is there a way to bypass the MMU2S

Hello,

I need to print a part using a rather soft FLEX filament.

Is there an easy way of bypassing the MMU2S (i.e. loading the filament directly on the extruder like in the regular MK3S), without having to reflash the firmware? I am afraid that even in Single material mode, the MMU2S will be pretty rough with the filament.

Any ideas?

Cheers

Luca

RE: Is there a way to bypass the MMU2S

Yes.

If you're just going to do a one-off print session, disconnect the power connection to the MMU2S and unscrew the bowden tube from the extruder.

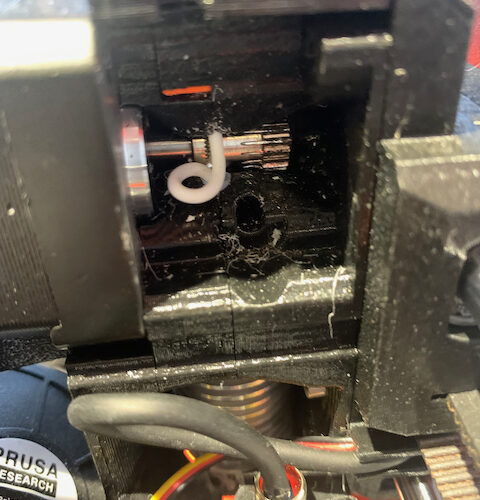

Feed the filament into the hole where the tube was and gently press the top of the idler on the right of the chimney inward. The hobbed gears will then load the filament in a similar manner to the MK3S without the MMU2S.

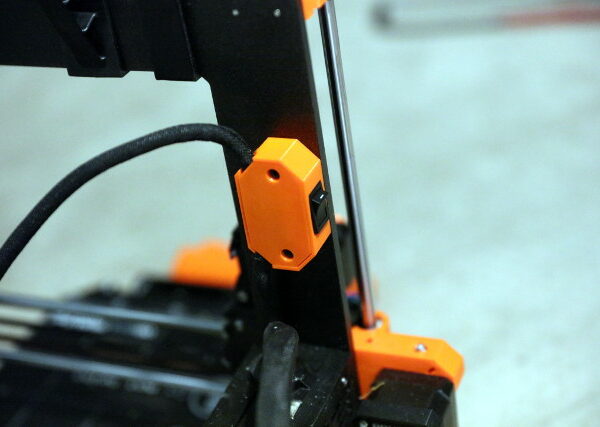

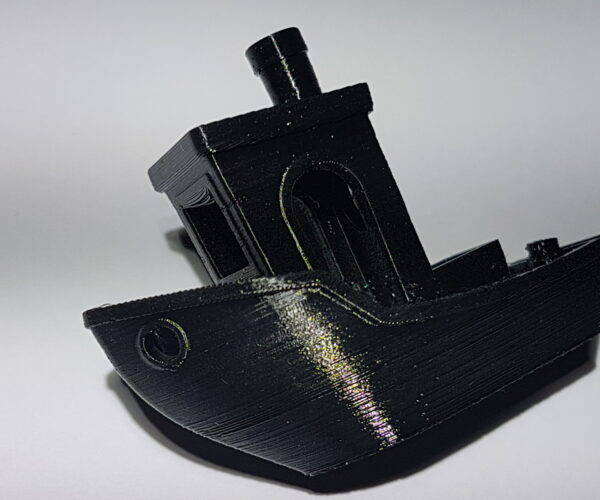

I installed a switch (the case for it is in the prints section here) to cut the power to the MMU2S, but you don't have to do that unless you plan on switching back and forth between regular MK3S and MMU2S-MK3S modes often.

No messing around with firmware necessary at all.

RE: Is there a way to bypass the MMU2S

Hello,

I need to print a part using a rather soft FLEX filament.

Is there an easy way of bypassing the MMU2S (i.e. loading the filament directly on the extruder like in the regular MK3S), without having to reflash the firmware? I am afraid that even in Single material mode, the MMU2S will be pretty rough with the filament.

Any ideas?

Cheers

Luca

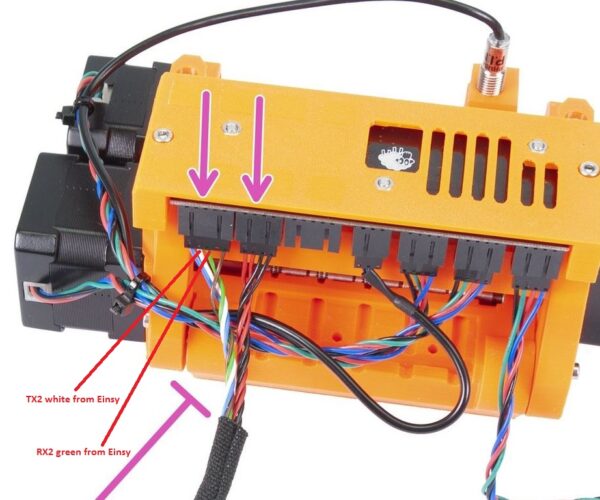

another possibility would be to disconnect the Rx/Tx data line from the MMU2 board (remove only data connector) and then reset the printer.

N/A is then displayed in the LCD menu.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Is there a way to bypass the MMU2S

Thanks for the great tips. 😀

Removing the power supply and/or the data connector was a challenge, as you have to reach the little plastic lever on the pub side to release the connector. I will definitely place an additional switch to control this.

The other challenge, is that the FLEX filament that I am using is extremely soft, therefore the IR sensor doesn't get triggered (I had to extract the sensor and block it with a piece of paper).

I am having jams on the extruder every 10 minutes, but I guess I will have to find the optimal temperature / print speed combination. Also playing with the extruder gear tension might help.

RE: Is there a way to bypass the MMU2S

This is EXACTLY why I added the switch, and whoever designed that little switch case obviously had the same thoughts.

One thing I may not have noted is that there are two unused tapped holes on the printer frame into which the screws for that switch case fit perfectly. It's almost like something like that was once intended or considered.

RE: Is there a way to bypass the MMU2S

@luca-vicini

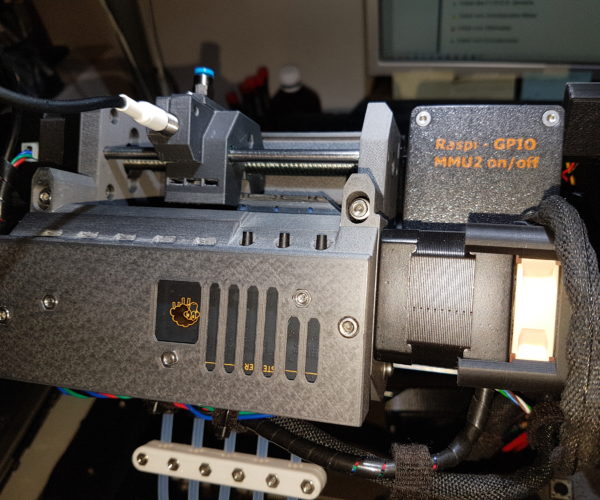

i solved it by controlling the data lines Tx and Rx using Raspberry GPIO's, a bashscript and PrusaSlicer.If the MMU2 is not needed, the script switches off the data lines via relay, resets the printer and starts printing. After printing is finished, everything is reset automatically to default settings.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Is there a way to bypass the MMU2S

Thanks for the pieces of advice.

After several days of trying. I give up with this type of FLEX filament. Far too soft and after 10 minutes of printing systematically the extruder jams.

I was considering putting a bit of PTFE lubricant in the PTFE tube, in the hope to prevent jamming. But I am not sure it will improve anything.

RE: Is there a way to bypass the MMU2S

You might ask here for very specific recommendation on the technique to print the brand and type of flex filament that you are attempting to use. I do know that the MK3S is capable of printing some flex filaments and that users have done so successfully, even though I have not done so myself yet.

RE: Is there a way to bypass the MMU2S

@luca-vicini

I have already printed some flex material and made sure that the feed values (1,5mm3/s) are very low, set z-hop and retract to zero and use an absolutely clean hotend (new brass nozzle). I switched off the nozzle fan and experimented a bit with the temperatures. I also installed 4/2.5 PTFE tubes against some recommendations. The spring tension on the idler should be kept very low. The filament should also be dry. Keep infill as low as possible to increase flexibility.

The print was not perfect, especially on the bridges, but at least I didn't have any blockages on the hotend. Used material - Flex Semisoft from Extrudr.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Is there a way to bypass the MMU2S

Thanks for the pieces of advice.

The material I am trying to use is Smartfil Flex. It's graded at 93A, and shouldn't be that hard to work with.

I used the "generic Flex" profile in Prusa Slicer and lowered the flow rate at 0.8mm3/s. My mistake is that I probably didn't condition well enough the filament roll before printing. I live in a fairly humid environment (100m from the sea with relative humidity of more than 80%). I will try again but I will leave the roll one night in a filament dryer

RE: Is there a way to bypass the MMU2S

@jsw

Can you tell me which switch you used? My question is more about what will fix the case, not about the switch function.

RE: Is there a way to bypass the MMU2S

Hi!

would you maybe be willing to post more details?

Best regards and thanks in advance,

Otto

@luca-vicini

i solved it by controlling the data lines Tx and Rx using Raspberry GPIO's, a bashscript and PrusaSlicer.If the MMU2 is not needed, the script switches off the data lines via relay, resets the printer and starts printing. After printing is finished, everything is reset automatically to default settings.

RE:

@jsw

Can you tell me which switch you used? My question is more about what will fix the case, not about the switch function.

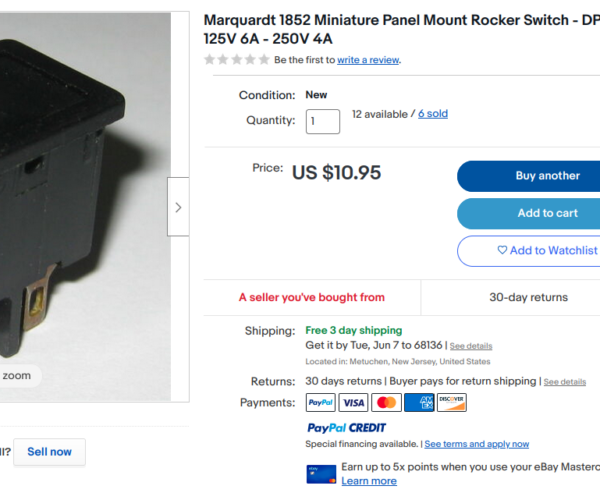

The switch is a fairly common item, described as:

Marquardt 1852 Miniature Panel Mount Rocker Switch - DPST - 125V 6A - 250V 4A Rocker switch manufactured by Marquardt Model: 1852 DPST contacts Rating 1: 6 A - 125 V AC Rating 2: 4 A - 250 V AC 1/10 HP 125-250 V AC Snaps into a .75" x .55" panel cutout Black color Switch overall dimensions (W x D x H): 21 mm x 15 mm x 25 mm ( 0.83" x 0.59" x 1.00")

It's important to break both the positive and negative power leads.

It snaps right in to the 3d printed casing. Expand the screen-scrape below to get more info.

RE: Is there a way to bypass the MMU2S

It's only necessary to interrupt the data lines Rx and Tx. This way the MK3S FW does'nt recognize the MMU2 anymore (N/A on LCD) and behaves like a MK3S without MMU2.

The contact can be interrupted or re-established either manually or via relays. I would first test it with a 2-way changeover switch. If that works, you can still control all via relays.

https://www.printables.com/de/model/15660-i3mk3-mmu2s-switch

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Is there a way to bypass the MMU2S

Hi and thanks!

any chance you share the code too?

It's only necessary to interrupt the data lines Rx and Tx. This way the MK3S FW does'nt recognize the MMU2 anymore (N/A on LCD) and behaves like a MK3S without MMU2.

The contact can be interrupted or re-established either manually or via relays. I would first test it with a 2-way changeover switch. If that works, you can still control all via relays.

https://www.printables.com/de/model/15660-i3mk3-mmu2s-switch

wbr,

Karl

RE: Is there a way to bypass the MMU2S

Hello folks. I found this thread while looking for ways to run some flex after bypassing my MMU2S by pulling the power line before I turn on the printer. I got the printer to load filament just the only thing is the filament is to soft to trigger the sensor for an auto load.

the only way the sensor reads is if I back out the idler tension until the screw comes out of the door. What have others done to get the filament sensor to read the flex?

If it matters I'm using the Overture TPU which is about a 95A in rating.

RE: Is there a way to bypass the MMU2S

Hello,

I need to print a part using a rather soft FLEX filament.

Is there an easy way of bypassing the MMU2S (i.e. loading the filament directly on the extruder like in the regular MK3S), without having to reflash the firmware? I am afraid that even in Single material mode, the MMU2S will be pretty rough with the filament.

Any ideas?

Cheers

Luca

Make the filament more rigid. The sensor will be more likely to be activated by a stiffer filament. Try switching to a different flex filament material, like PETG or nylon.

Customer feedback is gathered through the Burger King survey in order to raise the level of food and service at all BK locations. This survey is available to all BK customers. visit here www.myBKExperience.com Survey

RE:

If you're on the new firmware, you should disable auto-load entirely. This will allow you to manually start the load process and have the gears turning to pull the filament in.

Make sure idler tension is set *very* low so it's not squishing the filament.

If there are issues with the filament sensor not reading while it's loaded, you should be able to disable it.

If you have issues getting the filament loaded due to the softness of it, blast it with cold compressed air to temporarily stiffen it for the loading process.

Hello folks. I found this thread while looking for ways to run some flex after bypassing my MMU2S by pulling the power line before I turn on the printer. I got the printer to load filament just the only thing is the filament is to soft to trigger the sensor for an auto load.

the only way the sensor reads is if I back out the idler tension until the screw comes out of the door. What have others done to get the filament sensor to read the flex?

If it matters I'm using the Overture TPU which is about a 95A in rating.