RE: Frequent clogging with Verbatim BVOH

@karalt

when I was doing PLA and BVOH I was just using the stock prusament pla and bvoh settings. but I was also running my idler too tight.

So far since since doing the following, the petg and bvoh print is working:

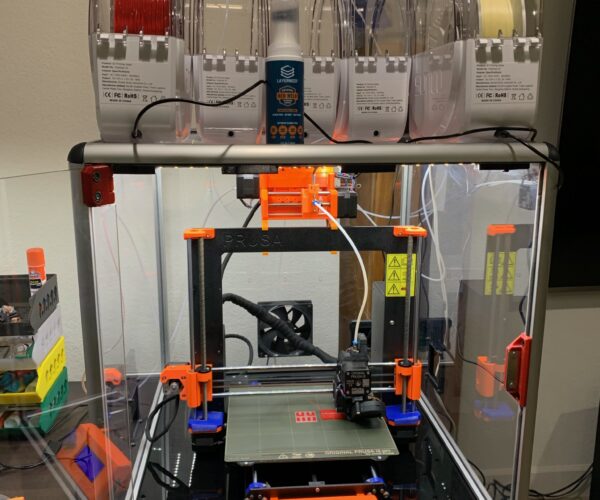

Reducing length of tubing to cut down on friction in path

Turning on the filament dryers the two filaments are feeding from

RE: Frequent clogging with Verbatim BVOH

@mdjuan

Yes I understand the temperature difference but prusa says it will will work.

https://help.prusa3d.com/en/article/mmu2s-and-soluble-materials-pva-bvoh_162860/

"For PETG you can practically only use BVOH. PLA can be printed with both PVA+ and BVOH."

RE: Frequent clogging with Verbatim BVOH

@ssill2

Interesting about running the idler too tight, did you have to do that to make it work or was that an accident?

The default profiles have not worked for me but I expected that since I have a different setup.

EDIT (just adding stuff): Was it the 5 PTFE tubes out the back of the MMU2S that you shortened? How short are they in your current setup? I have Capricorn XS tubes in the back but I'm not sure they are helping the situation. Seem to be higher quality, but may actually have a smaller diameter than my old tubes.

RE: Frequent clogging with Verbatim BVOH

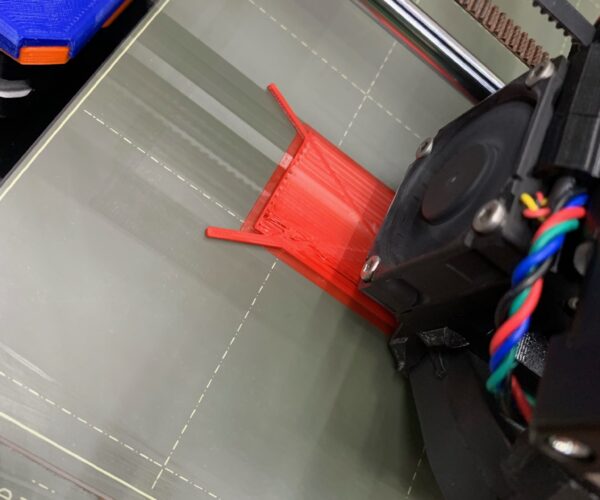

So I printed a temperature tower for my Gentleman's Grey Prusament PLA (that's fun to say) and found that, while 210 deg C looks the best, I can push it to 195 deg C before it starts skipping. I did this on 50% speed and am now repeating the temperature tower on 30% speed to see if that will let me push it any cooler.

What I noticed when it failed at the end of 180 deg C, is that the tip that came out looked just like a sharpened pencil. It did not have a slightly larger diameter near the tip, like I've seen before with some of my tips. I think this could be the fix for my problem and will continue to update.

RE: Frequent clogging with Verbatim BVOH

@karalt

That super slow. I don’t think you should have to go that slow

RE: Frequent clogging with Verbatim BVOH

@ssill2

I agree. I also have been trying to get this particular print to work for months so would be happy to have it working even if it means turning a 24 hour print into a 3 or 4 day print hahaha! But looks like 30% isn't making a difference anyways so I think I will try the PLA at 195 deg C and 50% speed.

RE: Frequent clogging with Verbatim BVOH

@karalt

I was doing 215c

RE: Frequent clogging with Verbatim BVOH

@karalt

After working with support for a few days and checking everything else they said that the only thing that could be causing it to blob on the purge tower itself was the idler bolt being too tight. it was causing the IR sensor to not register properly and thus it kept pushing filament down without the extruder moving.

I basically didn't shorten the tubes, but I reduced the number of bends so the filament moved through more easily. The tubes I have are 2mm ID and 4mm OD. I tried 3mm ID tubes but that made things worse.

I basically let the slack coil up outside the filament dryer.

RE: Frequent clogging with Verbatim BVOH

so my print failed again. part of it was I need to reslice this in a different orientation. I was mostly trying to test the soluble lol normally this would be printed face down and it would use a lot less filament and not even need supports. But it still doesn't address the fact that the the PETG and bvoh tend to blob. What's annoying is it can go hours between interventions so I don't know what the problem is. it definitely feels temperature related. I'm not sure how much I'm going to be able to mess with it this weekend, but I might print this part as it's intended to be oriented on my non mmu mk3s+ and pick a different model for the soluble testing.

RE: Frequent clogging with Verbatim BVOH

Ok, I'm getting back to this.

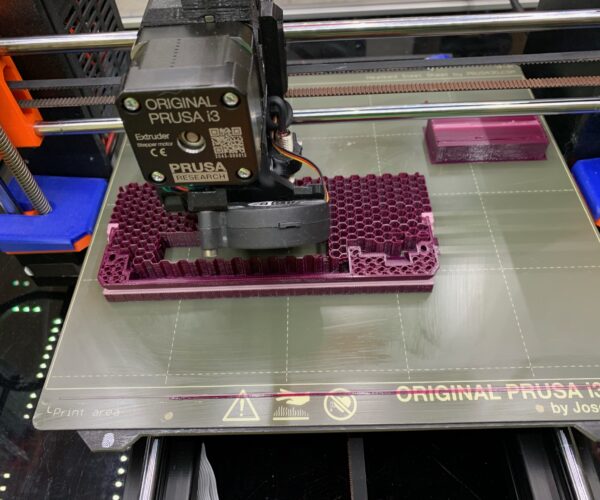

About to try this model

https://www.thingiverse.com/thing:16343

In Enzo Red Paramount3D PETG and Verbatim BVOH. It's a shorter (7-8h) print with 200'ish filament changes so I'll see if I can get this working reliably.

RE: Frequent clogging with Verbatim BVOH

So the filament switches seem to be ok. However, I'm running into this problem again

https://github.com/prusa3d/PrusaSlicer/issues/1948

I'm trying again with a big X through the wipe tower because that solved the poor adhesion I was seeing on purge tower. I'm slicing this with the latest 2.4.0 source so apparently the problem still exists lol

RE: Frequent clogging with Verbatim BVOH

I'm trying Push Plastics BVOH but it is getting stuck in the PTFE tube between the MMU2S and the extruder. This happens even on initial loading (no bulb end). There seems to be a lot of friction on BVOH and Push Plastics' BVOH which seems slightly thicker.

There are no mods to my MMU2S and I have no problems at all with it for PETG and only occasional problems with PLA if it's not well-dried.

Any suggestions? Switch to Verbatim?

RE: Frequent clogging with Verbatim BVOH

@gglockner

Verbatim is all I have experience with. I kind of thought it was a verbatim specific thing lol. I bought a spool of aquasys 120 that is supposed to be more compatible with petg temps but ended up having the same problems you are describing. It might be possible to adjust the ramming properties of your filament but that sounds like a pain lol. It’s the same reason that aquasys 120 is still sitting in its bag. I wish prusa would release a profile for it. As I recall is very stiff and you had to have pretty straight runs of ptfe. I might try it again sometime soon and see if I can get it to work again. The verbatim stuff does work for me though. It’s cheaper to order from prusa than Amazon lol

RE: Frequent clogging with Verbatim BVOH

@karalt

I was doing 215c

Basically what I am doing is an earlier recommendation on this thread that was to print temperature towers for the two filaments, choose the lowest working temperature and trying the print again. Had some bumps in the road printing the BVOH temp towers since it doesn't stick to the bed as well. Now I am printing a temp tower with some changes to help with bed adhesion (215 deg C on first layer, brim, lower z offset).

Also spoke with support and they were able to help me change some of my slicer settings so that it didn't put BVOH on the print bed for the model I am printing.

RE: Frequent clogging with Verbatim BVOH

@karalt

I'm printing something again with PETG and BVOH and I think it should be mentioned that it's good to dry the bvoh, even during print. When I started this print I loaded the bvoh and it was more difficult to push through the PTFE tubes. when drying the filament before and during print it slides through more easily which I think in the end results to less blobbing. This print has 125 filament changes and I've not had a single intervention so far.

That's my $0.02 🙂

RE: Frequent clogging with Verbatim BVOH

@ssill2

What brand BVOH? Push Plastic BVOH is sticking badly inside the PTFE tubes, so I'm trying to decide whether to spend $70 on Verbatim BVOH.