Filamentum PLA Cristal Clear: Mid-Print no more layers

I have a strange but reproduceable Problem with "Filamentum PLA Cristal Clear", only. Utilized the standard settings for "Filamentum PLA" in prusa slicer newest Version. Firmware is newest.

After a certain time 0.5-1 hour printing, the extruder starts to print in thin air. No filament is ejected any more. This happens reproductable.

But the same gcode with e.g. Prusament PLA runs absolutely fine.

First I thought about a problem with a certain height, but I can print higher objects e.g. a tower of 4 centimeters. The failing prints fail all at around 1 cm height.

The Cristal Clear filament is a bit stiffer and much smoother than Prusament PLA. So I assume it has something to do with slip in the extruder that builds up over time. An other problem may be the building up of heat in the extruder upper part making the filement to soft to be transported any more.

Any help appreciated

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Hi Volker,

I've also had this also happen with certain Filaments. Usually (when it first starts) there is a light clicking sound from the Extruder indicating filament is slipping. I've been able to solve this by increasing the Nozzle temperature another 5 to 10 degrees C. Rebuilding the G-Code is not necessary, you can adjust the Nozzle temp through the "tune" menu directly on the Prusa Printer. If your first layer temp is different, you will need to do this twice. Keep an eye on the Display screen.

Good luck, JT

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

@john-t13

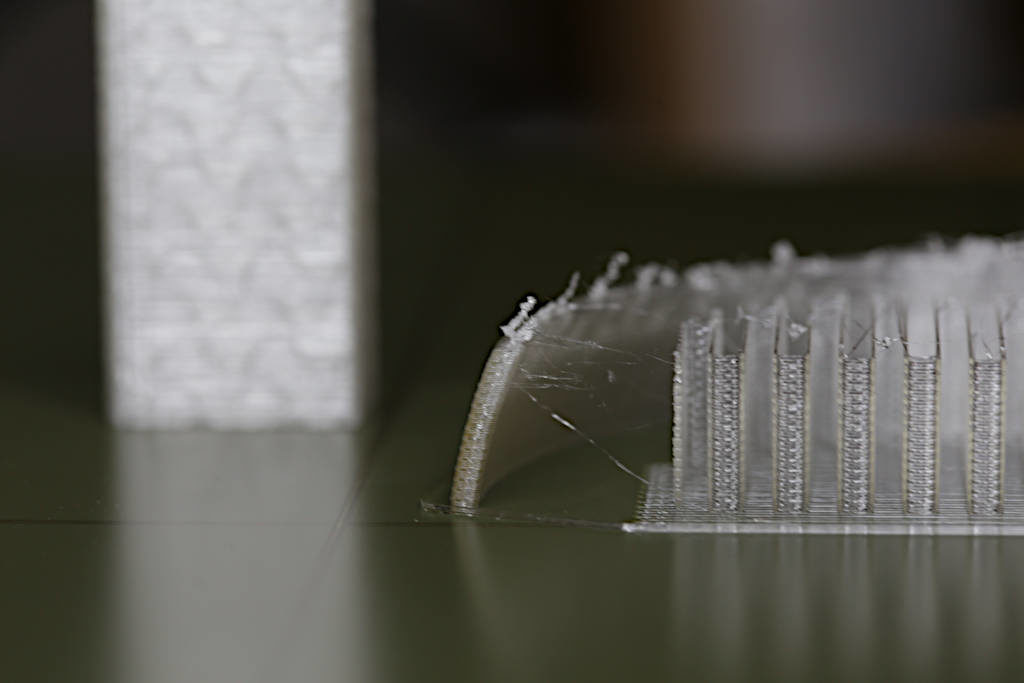

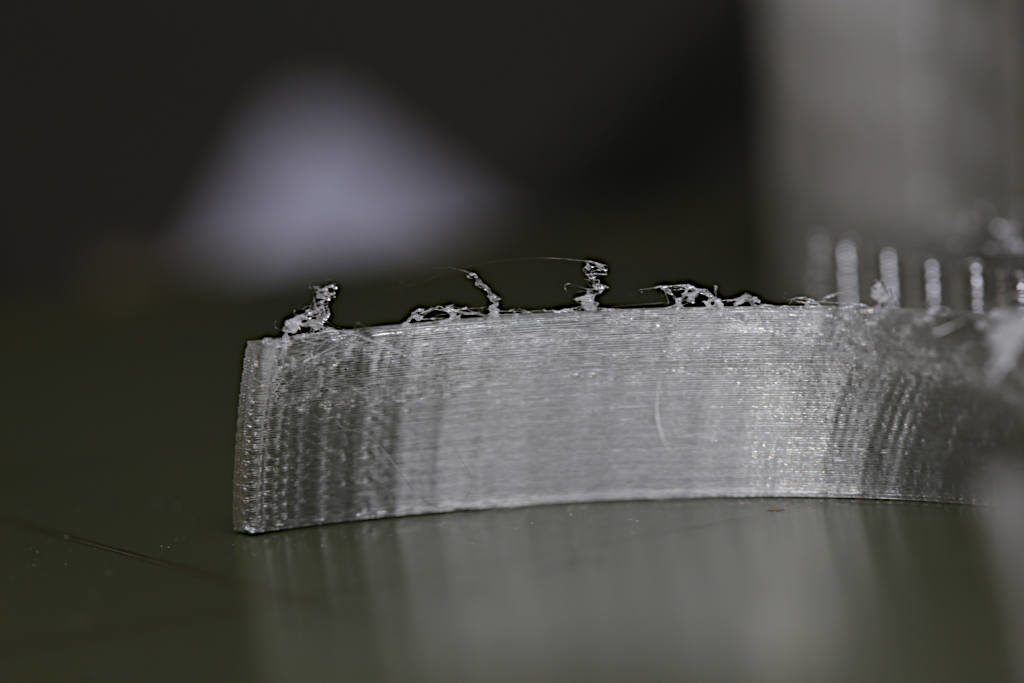

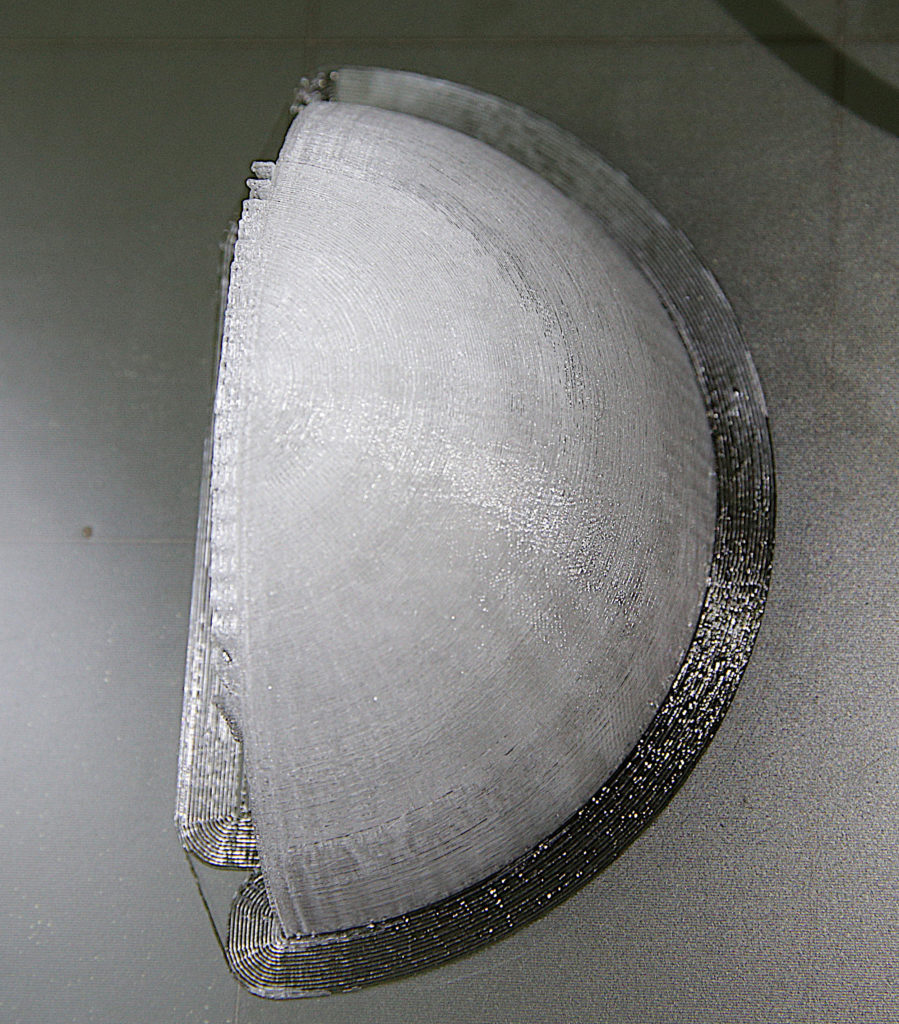

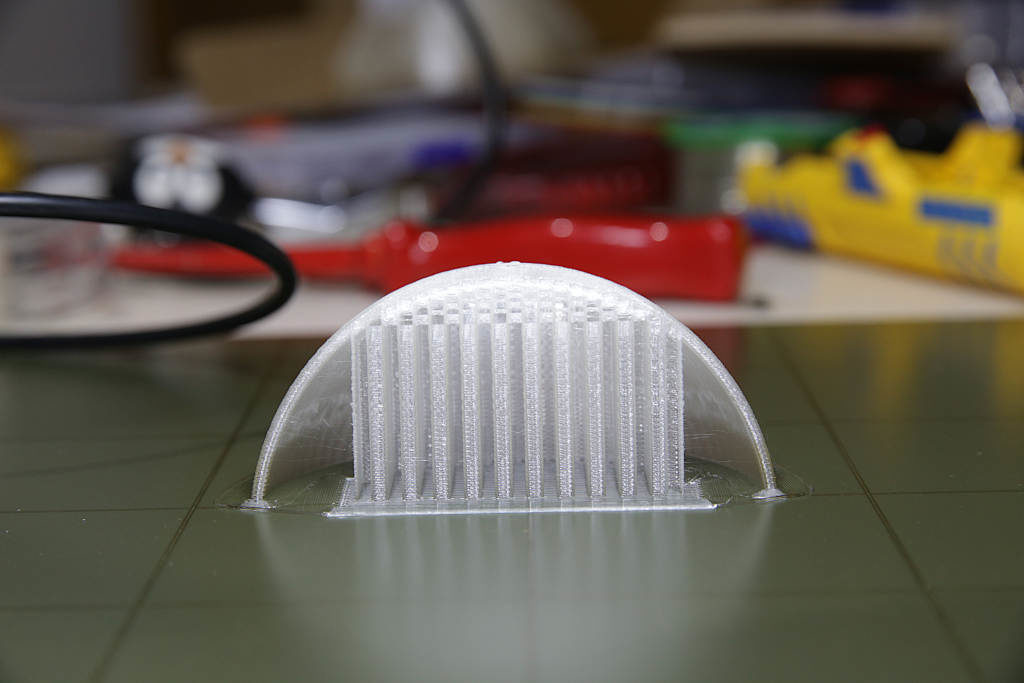

Some images of the problem.

Left the failed object. On the right for comparson a 10x20x40mm tower which prints flawlessly (in an other print session).

The support material shows no flaws till the effect. The object itself changes its desitiy in the upper third. So this may indicate a flow rate problem.

Irregularities in the upper third under the effect.

I will test your advice with the temp up 10 degrees. Test is running, so stay tuned.

Cheers,

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Hi there,

I had a similar issue with the PLA from a particular brand. The short story is that I finally solved it by throwing the 4 filament rolls into the garbage. It hurt a lot, but it made the problem disapear.

The long story is that after investing many hours on trials, I found out the the filament could perform only well when the object that I printed had a limited nummer of retractions on the g-code. This means for bulky objects with almost no details, the prints went well, for detailed prints the extruder was jammed always more or less at the same layer height, depending on the object.

I overcame the problem by setting the retraction lenght to zero, or by setting the extruder temperature to 230*C and lowering the extrusion speed to 50%. I had a lot of stringing, but the print was always finished without jammings on the extruder.

So maybe the filament is not 100% compatible with your printer.

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

So maybe the filament is not 100% compatible with your printer.

Since I ordered the filament from Prusa https://shop.prusa3d.com/de/filament/189-pla-kristallklar-transparent-750g.html I assumed that the material is compatible :-).

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

It could be heat creep from the Extrude motor down the shaft softening some PLA's. There is discussion about this on Github regarding changes in the Firmware. I added some heatsinks that seem to work. Others added a fan.

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

@jmone

May you point me to the source of the heat sinks, please? A will give them a try.

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Just to chime in and say I'm having a similar problem. It only seems to occur with certain transparent filaments for me and on objects with a lot of retractions. Please report back on your results with heat sinks or fans. Seems like a work around to me 🙁

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Dear @all

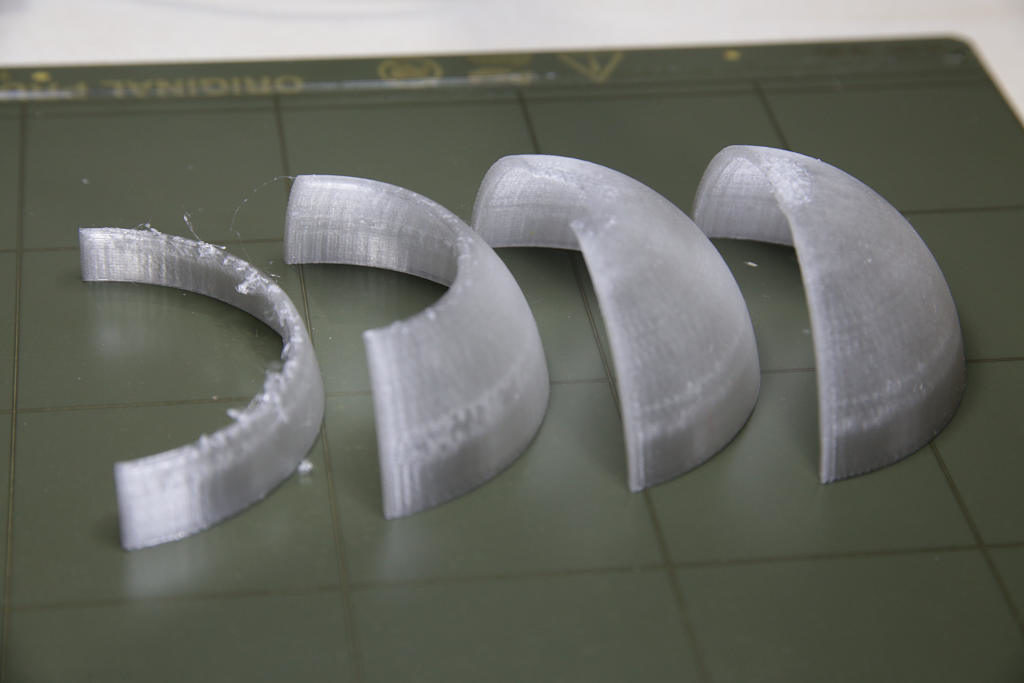

Here a series of approaching the target:

From left to right:

- Origional prusa slicer setting for Filamantum PLA

- Added temp 10 degrees (Thank you @john-t13)

- Added temp 10 degrees and reduced retraction from 0.8mm to 0.5mm. (Thank you @gerardo-w)

- Added temp 20 degrees and reduced retraction from 0.8mm to 0.5mm. Also changed infill to 100% to reduce the retractions due to infill.

I am hopefull that the comment of @jmone will do the rest. The extruder stepper becomes really hot! Since the prusa in enclosed there where can dissipate and this stepper is anytime above the heatbed.

Cheers,

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Wow, good job.

I agree with you, the heat is much more difficult to dissipate or escape when you work with an enclosure. I have read many times that using an enclosure for extruding with PLA is not that good. It makes sense, since PLA has also a very low softening temperature (glass transition temperature). Heat radiation from the bed itself may also contribute, but I got also filament jammings even at the higher Z positions.

One good observation is that the motor becomes very hot. I can confirm that. It would be interesting to find out, if the motor reaches the same temperature with another more easy to process filament where no jamming happens. I don't know if the motor gets hotter when it needs more power to do the same work. If yes, stiffer filaments will lead to a hotter motor, since they are more difficult to extrude (lower melt flow index or just higher melt viscosity).

I am also interested on that heat sinks 🙂 ....but I also want to put a thermocouple or sensor near the motor first.

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Wow, good job.

You are welcome! Wihout your (plural) generous help I would have simply given up.

I have read many times that using an enclosure for extruding with PLA is not that good. It makes sense, since PLA has also a very low softening temperature (glass transition temperature).

I utilize the IKEA table enclosure, since my printer is operated in a not well insulated room at 800 meter elevation in the alpine mountains. Room temperature is at 18 degrees and still falling. Currently a storm is rocking our home. Without the enclosure warping becomes a huge issue under such conditions. But with this enclosure any print PETG/PLA comes out fine

I also print filaflex and nylon which is both a PAIN to calibrate but it works, with nice outcome. But after mastering so many materials I was devastated by this dammed Filamentum PLA Cristal Clear, which should print easier than Filaflex or Nylon.

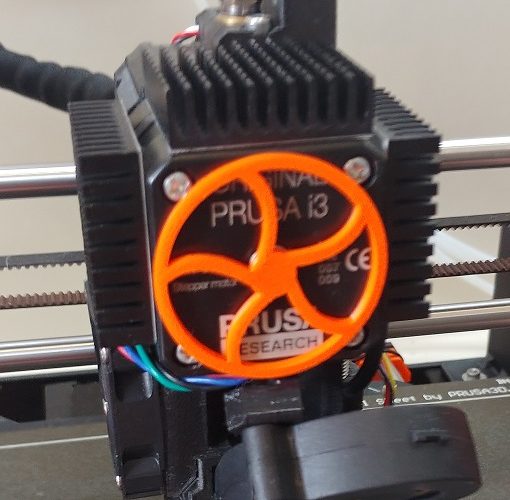

But help is comming: Just found a powerfull and silent 12V 32mm fan in my attic 🙂 So currently I am printing the fan chassis that @jmon mentioned (Link). Have already finished the step down power supply from 24->12V and the cables.

So please stay tuned! Tomorrow I will post new results.

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

With the new extrusion stepper cooling, the outcome is excactly the same.

The Extrusion stepper is quite cool now, but this does not influence the printing at all.

Cheers,

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

@volker-jaenisch

Nice analysis! JT

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Dear Volker,

thank you for sharing your results.

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

It was worth a shot as I too had the issue but with the heat sinks it stopped. (note: I just used 35mm fins with self adhesive backing from some random on ebay)

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

@all

Thanks for your warm words.

Today I replaced the side fan with my powerfull 12V fan - same outcome.

So I am thinking that the problem is not realated to temperature problems in the extruder.

But there are some other posibilities:

- Friction

- Shrinking

1) If the extruder rises the friction in the tube may change. Also at a certain height the tube connects with the ceiling of the enclosement leading to a slight deformation. I neglected this problem so far since the initial problems have occured below this critical mark. But to solve this I will need a new enclosement and this needs time. Tomorrow I will move the printer to a warmer location and try without enclosement, to check for a friction problem.

2) Also with the height the intensity of the heatbed dimishes. And overall contraction becomes pronounced with height. I do not thinkt that the slicer takes into account that the object it prints will shrink while beeing printed? There no shringage parameter in the filament tab of the slicer.

The object length is 79.21mm and the printed length is 78.45mm wich derives a shrinkage of roughly 1%. This is low for PLA which is said to shrink 3%.

But I do not think that shrinking is the issue. If it where then why was I able to print higher objects with only changing parameters like nozzle temperature? Which has no influence in the overall shrinking. And if it where the shrinking, why does the nozzle jam? If a layer is missing the material flow would not stop.

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

First successfull print!

- Printed with no enclosement (23 Degrees abient temp).

- Temp 230/60 degrees and reduced retraction from 0.8mm to 0.5mm.

I also noticed a squeaking sound at the end last 10% of the print. I assume that is the nozzle scratching an the object. So I tune down the heatbed temperature to ambient to shrink the object by cooling. Also I reduced the flowrate to 70%.

I think that the following happens:

1) The filament has a high melting point. If the nozzle is jammed I need much more than 230° to get it pushed free.

2) Due to the 20° higher printing temperature the flow parameters of the preset may no longer be correct, so too much material is ejected. Therefore with additional height the material bulks up and then the nozzel starts squeaking and finally catching completely causing the nozzel to jam.

3) Reducing the retraction helped since this reduces the peak outflow and so reduced the probability of jamming.

So I will try again with the enclosement and just lower the flow rate from 90 to 80 points.

Cheers,

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

Sorry have to correct myself.

So I will try again with the enclosement and just lower the flow rate from 90 to 80 points.

Lowering the flow from 1.0 to 0.9.

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

This works!

- Filamentum PLA Cristal Clear

- Temperature 230/60

- Extrusion-Faktor 0.9

Can anybody please verify?

Cheers,

Volker

RE: Filamentum PLA Cristal Clear: Mid-Print no more layers

not all filaments are exact same size! thats why that extrusion flow rate is adjustable. 1.75mm filaments typically have a +/_ tolerance and it will vary from manufacturer. typicaly 0.9-1.1 is a normal change (to my knowledge) depending on the filament.