Cracks and warping on the wipe tower

Hello,

I am at my first prints with soluble supports. I have an annoying problem.

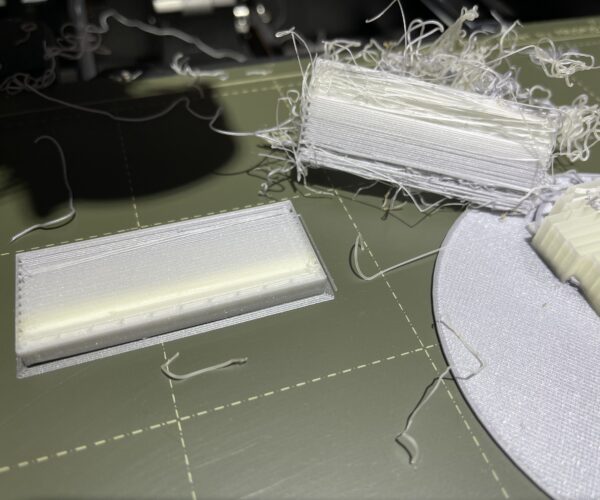

On several layers, the wipe tower crack and bend, making the print fail, since eventually the tower falls apart.

Why is this happening? Are there any solutions?

RE: Cracks and warping on the wipe tower

well what materials are you using?, certainly at this point in the game you should know that you need to pass that information and more along, why would you even post a question this vague? your not new here.

I don't mean to sound rude, but com'on man

The Filament Whisperer

RE: Cracks and warping on the wipe tower

Choose 0.20 mm soluble interface in print settings.

The supports will be created out of your base material and only the contact points with your model will be soluble.

This will greatly reduce the number of material changes, reduce total print time and total cost, while strengthen your wipe tower.

Having problems with bed adhesion every morning...

RE: Cracks and warping on the wipe tower

Hi @swiss_cheese,

Apologies for the post written in a rush and at the highest of frustration.

I am printing with Prusament PLA and Verbatim BVOH (just two filaments). The temperature settings are the default from the PrusaSlicer profiles. The only parameter that I am changing from default are the number of cooling moves (two instead of one).

The print profile I am using is 0.15mm SOLUBLE FULL. Unfortunately I cannot use the 0.15mm SOLUBLE INTERFACE as the model has a rather intricate geometry and I wouldn't be able to extract the PLA support material from certain places.

I believe the cracks are coming from the difference in thermal expansion coefficients from PLA and BVOH, therefore my next step is to print in an enclosure and to make sure that the wipe tower is square instead of rectangular.

My question here, since this is one of my first tests with soluble supports, is if this kind of problems are common with Verbatim BVOH and how to mitigate them.