Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

I'm trying to get soluble supports working with my MMU2; I am using PrusaSlicer-2.1.0. Specifically, I've got my extruders set up so extruder #1 is Prusament PLA, and extruder #5 is Verbatim BVOH (soluble). I then try to select extruder #5 for my "support material/raft interface material", and it then gives me the classic error of "The wipe tower currently supports the non-soluble supports only". If I select "yes", it switches my support interface material back to zero, and if I select "no", it disables the wipe tower.

How the heck do I enable both?

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

Did you set the printer as MK3S MMU2S and then soluble full or soluble interface from print settings? If yes, go to print settings, Multiple extruders and choose the extruders which you want to print (numbers). I hope it will help.

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

It turns out that I had to turn on "Synchronize with object layers". That solved my problem...

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

It turns out that I had to turn on "Synchronize with object layers". That solved my problem...

That option is grayed out for me. I'm using PrusaSlicer 2.2.0, with a printer profile set to Original Prusa i3 MK3S MMU2S. I cannot figure out how to get soluble supports to print with a wipe tower. The slicer can generate supports with the same material as the printed part, or soluble support without a wipe tower, but not support with a wipe tower.

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

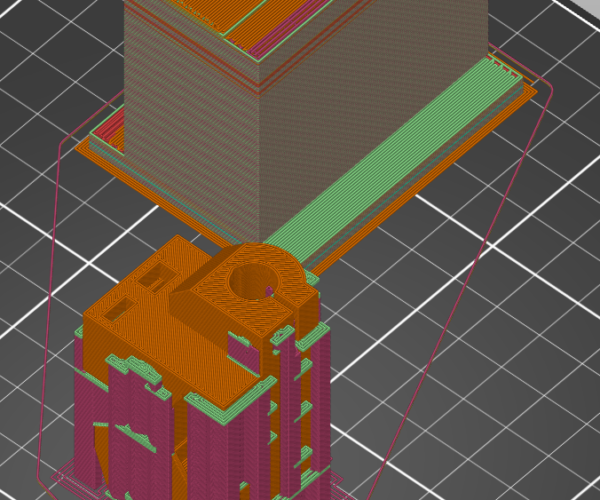

I just discovered that Slicer 2.2 supports both wipe tower and supports, with soluble interfaces or not. When you try to set soluble supports it shows such dialog:

But don't worry. Let Slicer untick "wipe tower" in print settings. Then you setup what you need (support material extruders, support-model distance to "0 mm (soluble)") then go back to print settings and reenable wipe tower. Then "slice now". And you get your model sliced to eg PET, with PET supports, PVA interfaces AND wipe tower.

BTW for 97% of models it's enough to set "wipe to infill" and disable wipe tower. The rest 3% are 1. very small models where you don't want to mix colors on perimeters, 2. models with soluble supports which you need good concistent infill or ones too small with risk of printing perimeters from PVA or 3. models where you experimentally combine PLA with PET-G (I did the latter combination with success at 235*C for both materials as I didn't have blue PLA, only blue PET :P)

I also print with "Soluble PLA" material. I load regular PLA to #5 extruder, and for this material I set a copy of regular PLA profile. I have two such copies - "Hot Soluble PLA" and "Cold soluble PLA" with PLA temperatures set to PETG temperature (if I don't want to wait for cool down after filament change) and to 180*C (easier to scrap PLA that diffused with PET, much easier to remove PET support from PLA interface). PLA interface isn't soluble but is much easier removable from PET than PET-support.

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

So, wipe tower with soluble supports is possible.

Yeah, I figured that out eventually also. You have to select one of the "soluble support" profiles. I printed a some of my 4-piece interlocking puzzle ring bracelet designs using PVA support, and noticed that PVA doesn't dissolve completely on its own; you have to work at picking out the gelatinous mass from the crevices of your part after soaking in water. Soak for half an hour, remove a bit of support, repeat many times throughout an afternoon until it's all clean.

I also noticed that PVA leaves something behind on my powder-coated steel sheet, and it doesn't wash off even with water. It seems like parts stick better to those areas where PVA has been, which is a good thing because that powder-coat sheet of mine has never stuck well to PLA.

Another thing I learned from this experience is that if you need support mostly on one side, then put the wipe tower on that side, so you don't get PVA stringing across your print as the nozzle travels to the wipe tower. In the case of my puzzle ring bracelet, I needed support all around the ring, but the wipe tower fit nicely inside, so I got no stringing on the outside.

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

For people returning to this topic in the future, I did a bunch of tests with using PLA & PETG in same print and found that using different materials has a huge impact on model strength. For a typical purge volume of 250mm³ you can expect layer adhesion strength to be 1/5 of what it should be. Sadly only way to get around this is to purge crazy amounts of plastic ~2500mm³, or getting a 3D printer with at least two hotends

www.antalife.com

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

For people returning to this topic in the future, I did a bunch of tests with using PLA & PETG in same print and found that using different materials has a huge impact on model strength. For a typical purge volume of 250mm³ you can expect layer adhesion strength to be 1/5 of what it should be. Sadly only way to get around this is to purge crazy amounts of plastic ~2500mm³, or getting a 3D printer with at least two hotends

@antalife - did you ever try the script that @nikolai-r recommended in that thread? I saw he also suggested the "dribbling" slicer fork you're using may be mixing the filament materials in the nozzle, making it harder to purge completely.

That said, I have also observed with PLA+PVA that my print comes out pretty weak. One part I had with a lot of little crevices split while I was picking the water-softened PVA from it, and I had to superglue it back together after it was all clean and dry. I originally thought the weakness was due to PVA stringing across the part during tool changes, but after reading your thread I think the problem is likely insufficient purging.

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

@anachronist

Regarding PrusaSlicer 2.2.0 DRIBBLING by antimix, in the end we figured out that it would not be causing any issues:

Ah I see what you mean, when you dribble PLA at 235C (outside recommended PLA temp) you are going to mix OK PLA with one that has been heated up "too much". But the thing is that my dribbling temperature is 180C for PLA and 205C for PETG, so I would not be running into the issue you have described. The nozzle is only heated up to 235C when it's purging into the block

Also thanks for the feedback, glad to hear more people experienced similar issues

www.antalife.com

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

Sadly only way to get around this is to purge crazy amounts of plastic ~2500mm³, or getting a 3D printer with at least two hotends

Regarding that... I wanted to add that I bought the Prusa MK3S because of its reputation of needing minimal tinkering and fussing, and it has met that expectation (admittedly less so with the MMU2S add-on, but for the most part since I worked out all the kinks during that long first night I tried to use it, it has been relatively problem-free). A dual-extruder printer would come with its own separate set of nightmares and based on what I've read, I would be doing more tinkering, fussing, and calibrating it than I would be spending actually designing my designs and printing them. So on the balance, the part weakness resulting from multi-material printing is something I'll have to learn to live with, and unfortunately do some tinkering to mitigate the effects.

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

@anachronist

Yea, sadly like with anything in life good things come at a price D:

If I had the cash I would get the Ultimaker S5, which is a good industrial-tier dual-extrusion printer

https://ultimaker.com/3d-printers/ultimaker-s5

www.antalife.com

RE: Can't use wipe tower with soluble supports? [PrusaSlicer-2.1.0]

Weeks and weeks and weeks of banging my head against in the wall, re-reading the error message, I think I actually lost sleep over this - and Synchronize was the key! Six years later, thanks!