Problem loadin/unloading during prints

Hi all,

I’ve been having a problem where the mmu gets stuck during prints, and was wondering if anyone could offer troubleshooting tips. At the start of the print, all filaments will load properly, and some of the initial switches will be ok.

After a while, however, the filament will unload and the next will fail to load. The mmu stops, red light flashing slowly.

I’ve read the common problems post, and was wondering if anyone if anyone had tips on what to look for.

Thanks!

Re: Problem loadin/unloading during prints

Another thing I noticed - filament switching happens fine for a while and often seems to get stuck at the exact same layer heights. In particular, it gets stuck after switching hasn't occurred for a while.

Could the filaments that aren't in use be getting grinded while the other filament is printing?

Re: Problem loadin/unloading during prints

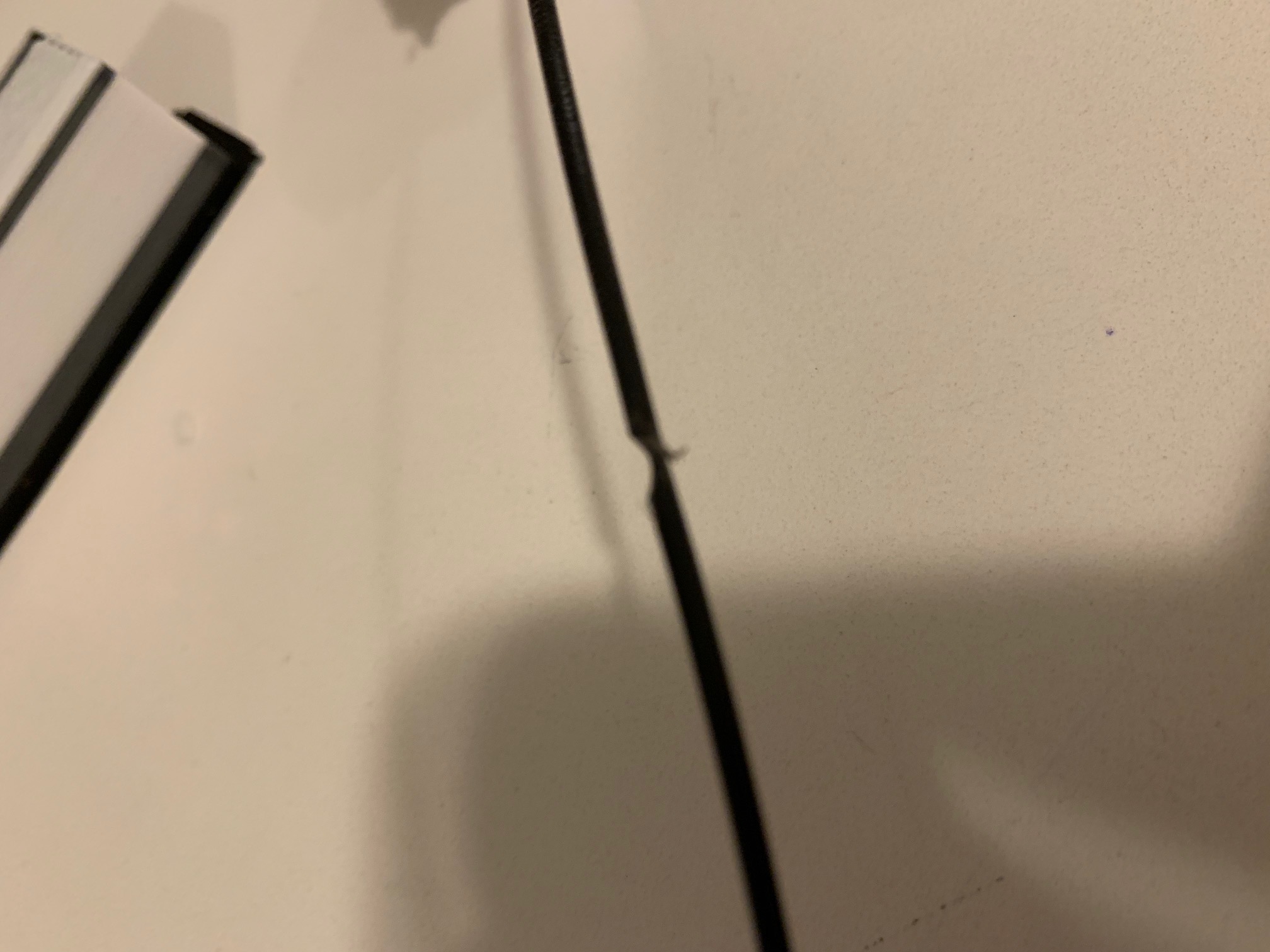

I dug a little bit more, and found that at least one of the causes was stripped filament (that looks like this) in the MMU idler. I've attached a picture - what is the problem here? Tension on the idler?

The root cause of this is that the filament got stuck somewhere, and when the MMU tried to push or pull it, it just chewed a chunk out of the filament.

This will happen every time the filament gets stuck. Any time there's a load or unload failure you should look for the bite in the filament and trim it off, because the MMU will get stuck on the bite the next time it tries to load that filament.

Re: Problem loadin/unloading during prints

The root cause of this is that the filament got stuck somewhere, and when the MMU tried to push or pull it, it just chewed a chunk out of the filament.

Thanks!

What are the typical places the MMU can get stuck loading/unloading? I imagine I should check the alignment of the gears in the MMU/extruder - what else could be the source of the problem?

Re: Problem loadin/unloading during prints

The only time I've gotten stuck unloading the tip was too fat (I was testing too low a temp during ram/unload) and the filament could not be pulled out of the extruder. Jammed somewhere in the hot end.

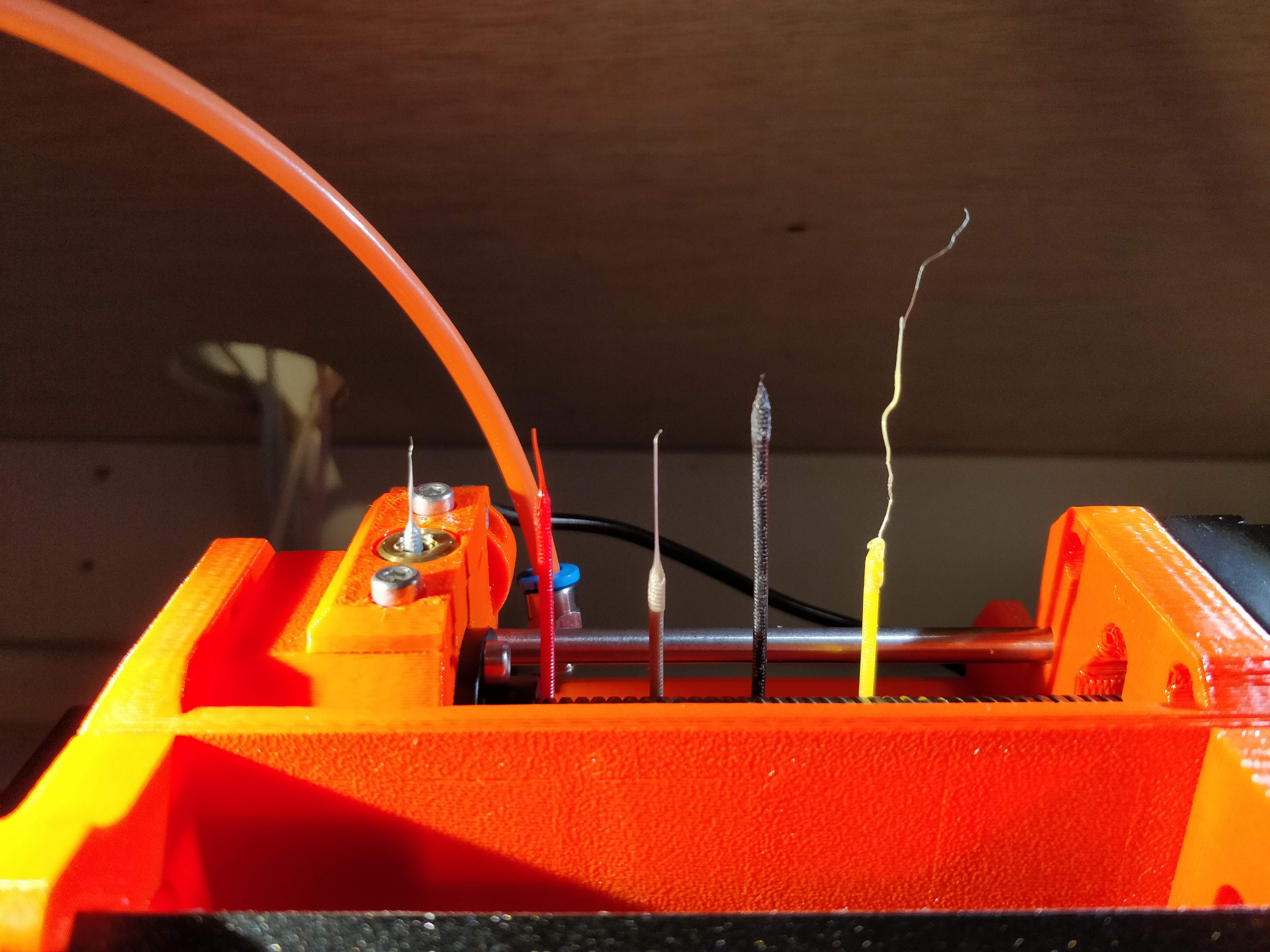

Above that, the only real point it can get caught is in the extruder bondtech gear (if the extruder hasn't ejected it cleanly and is still gripping), or more likely at the entrance to the orange PTFE.

If it's getting stuck, it's either because the tip is too fat (try higher temp or different ram/unload settings), or caught in a tangle of little filaments from previous tips. I've seen little wads of filament (think tiny loose cotton ball) multiple times at various places. I'm assuming they are building up in the finda over time as the selector moves and cuts off the stringy tip, and eventually move up and down the orange tube with the filament, adding up over time.

Re: Problem loadin/unloading during prints

Above that, the only real point it can get caught is in the extruder bondtech gear (if the extruder hasn't ejected it cleanly and is still gripping), or more likely at the entrance to the orange PTFE.

Oh ye of little imagination!

I've had filament get stuck pretty much everywhere in the system:

I'll admit that I'm pushing the envelope trying to use crappy brittle filament with the MMU (you really shouldn't have to worry about filament breaking inside the bowden tube). But it is possible for filament to get stuck almost anywhere.

Re: Problem loadin/unloading during prints

If it's getting stuck, it's either because the tip is too fat (try higher temp or different ram/unload settings), or caught in a tangle of little filaments from previous tips. I've seen little wads of filament (think tiny loose cotton ball) multiple times at various places. I'm assuming they are building up in the finda over time as the selector moves and cuts off the stringy tip, and eventually move up and down the orange tube with the filament, adding up over time.

Thanks for both your replies! I discovered that it might be getting stuck in the bowden tube. I cut the filament at the idler, and removed the tube with the filament still inside. The filament strongly resisted moving. Whether the tip is too fat, or getting curled - what is the recommended fix? I'm printing at 205. How do I adjust the ram/unload settings, and what changes would I want to try?

Thanks again!

Re: Problem loadin/unloading during prints

If it's getting stuck, it's either because the tip is too fat (try higher temp or different ram/unload settings), or caught in a tangle of little filaments from previous tips. I've seen little wads of filament (think tiny loose cotton ball) multiple times at various places. I'm assuming they are building up in the finda over time as the selector moves and cuts off the stringy tip, and eventually move up and down the orange tube with the filament, adding up over time.

Thanks for both your replies! I discovered that it might be getting stuck in the bowden tube. I cut the filament at the idler, and removed the tube with the filament still inside. The filament strongly resisted moving. Whether the tip is too fat, or getting curled - what is the recommended fix? I'm printing at 205. How do I adjust the ram/unload settings, and what changes would I want to try?

Thanks again!

There's not a lot of experience out there to go on yet, so you're a little on your own.

The main thing is to only change one thing at a time. Usually I start with temperature. If there's threads or pigtails on the filament I'll drop the print temperature five degrees at a time until it starts causing other print problems.

I think the idea behind ramming is to quickly expel any softened filament so that what's left is relatively cool and is less likely to string. But one hard-to-control variable is how quickly the printer has been printing before the unload starts, which can affect how much the end of the filament has had time to soften in the hot zone.

One very useful resource would be for someone to make a matrix of photos that show what the tip looks like as you change the temperature, ramming volume, ramming speed, etc., while keeping everything else the same. That way you could look for a picture that matches your filament and get a sense for what would happen if you changed some variable. That could easily be dozens (or hundreds!) of photos, though, and a huge PITA to make all the gcodes and do all the testing.

Re: Problem loadin/unloading during prints

I like that idea, Peter.

I'd really like a macro that makes the MMU eject filament WITHOUT moving the selector, only the drum.

Just feed out 100 mm on each channel in turn.

My REAL issues stem from grinding the back of the filament, I throw away more 40-cm-at-a-time lengths than I put into waste towers.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Problem loadin/unloading during prints

Another thing I noticed - filament switching happens fine for a while and often seems to get stuck at the exact same layer heights. In particular, it gets stuck after switching hasn't occurred for a while.

Could the filaments that aren't in use be getting grinded while the other filament is printing?

If it's grinding the unused filament, the grooves would be near the tip.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Problem loadin/unloading during prints

My REAL issues stem from grinding the back of the filament, I throw away more 40-cm-at-a-time lengths than I put into waste towers.

Good thing filament is cheap these days!

Right now I'm printing with some very brittle Hatchbox transparent ABS. The stuff is crap, but I'm too cheap to just throw away a spool of filament.

So I'm secretly happy every time I have to throw away a half meter of the stuff (which, let's face it, is only 1.2g). It gets me that much closer to being done with this junk.

Re: Problem loadin/unloading during prints

I'm convinced the yanking on the filament is breaking it. I've had breaks before, but I have more per day not than I had in a typical month of printing before the MMU.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Problem loadin/unloading during prints

I'm convinced the yanking on the filament is breaking it. I've had breaks before, but I have more per day not than I had in a typical month of printing before the MMU.

If you're using good quality filament it should not break with the MMU.

If you're using poor quality filament that's prone to breaking, it will break more often with the MMU.

Solution: Use better filament.

Re: Problem loadin/unloading during prints

Great. Except it isn't the only time I've seen breaking.

And saying "your honda won't take the corner at the same speed as the ferrari, so junk it" would keep a lot of people from getting to work. 🙂

To the extent the problem can be understood and solved, I'd like to. I've had (and tuned out, and got back, and tuned out, and got back....) stringing, tangles, misfeeds, etc. No meant offensively, but sticking my fingers in my ears and chanting "I'm not listening" won't do any more good here than it does me elsewhere.

By changing the speed of the recieveing gears and the feed distance, I went from one to the other. Some is $12/kg, some is 40. But they all work fine if I drive it like a honda.

Just need to get a handle on things.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Problem loadin/unloading during prints

Great. Except it isn't the only time I've seen breaking.

And saying "your honda won't take the corner at the same speed as the ferrari, so junk it" would keep a lot of people from getting to work. 🙂

To the extent the problem can be understood and solved, I'd like to. I've had (and tuned out, and got back, and tuned out, and got back....) stringing, tangles, misfeeds, etc. No meant offensively, but sticking my fingers in my ears and chanting "I'm not listening" won't do any more good here than it does me elsewhere.

To extend your metaphor a little, can you please clarify whether your Honda is skidding when it goes around the corner, or are the wheels falling off? Because if the wheels are falling off, your Honda is junk and you need to replace it. But if it's just skidding then let's talk about how you can take that corner a little differently.

For what it's worth, those pictures don't show broken filament, they show the damage caused by the MMU gears when filament gets stuck somewhere in the system. I apologize if I'm being obnoxiously pedantic, but the root cause of stuck vs. broken filament is very different.

I've got a pile of over 50 different filaments of different materials, manufacturers, etc. So far, with persistence I've been able to get everything to work reliably (I haven't tried all my spools yet!) except for the crap transparent ABS from Hatchbox, which is brittle and often breaks like uncooked spaghetti. But I knew that filament was crap before, and it has problems breaking even without the MMU. The MMU makes the problems much worse.

So yes, you are correct that the MMU puts more stress on the filament than a normal feed path. But it's no so far out of the ordinary that good quality filament should be breaking. If your filament is actually breaking, as in snapping like spaghetti, then the problem is your filament. But if your filament is getting stuck, then the root cause is probably something different.

Re: Problem loadin/unloading during prints

First off, something I probably have to do up front:

nom nom nom

That's not about picturing one thing while whining about another - I was merely trying to say that a problem I would have chalked up to materials was solved by considering the whole process. Perhaps a more insightful way to put it is if you fix the problem with premium filament, you're really just covering up the issue.

With that said, 4 of my rolls of ~$15/kg filament arrived, and since loading them I've dropped from multiple jams per hour to one in half a day and I suspect it was a fluke from poor loading on my part. You wouldn't think my $13 filament was that much worse (I got it from a friend, I don't even know the brand), but it sure was. In slightly more detail - earlier I was able to get this filament to have nice ends but was suffering from grinding, in the process of sorting that the ugly tips came back. I know two of my 3 trouble filaments can print reliably with the right settings.

But it brings me back to my point: The spool giving me the most trouble was the same brand as the ones that saved my print! I would really like to learn how to adjust my ramming and related settings to get these trickier materials to work... Specifically because I want to use tricky materials. Flex and especially genuine, generic, CHEAP PVA.

I can solve the issue for PLA with better PLA, but to make non-recommended materials perform I feel a deeper understanding of the controls would help me pioneer (and share!) in this area.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Problem loadin/unloading during prints

I've spent the last two weeks battling Matterhackers Build filament. Some spools were worse than others, but fundamentally I've never been able to complete a print without filament strings building up somewhere. I blamed the MMU2 and kept trying.

I bought two (very cheap) rolls of Inland PLA, went with some basic settings, and have never seen a string or a load/unload fail.

At this point I'm convinced I had a bad batch of filament (or MH Build is all bad and that's why it is cheap, no opinion). I will say filament can make a big difference, however. I know some say it'll work with any filament, but I'll attest to the fact that it is easier with some filaments than others.

If you are having major issues and have followed all the troubleshooting tips here, picking up a couple of rolls of fresh filament of a different type is definitely a useful step.