MMU2s Single Unload Fails

I installed my MMU2S a couple of weeks ago and have finally got it working reliably for multi-color prints. However, I am now having problems with single color prints. When a print finishes (or I stop it manually), the filament gets stuck in the extruder and won't unload. It is getting stuck somewhere above the extruder gear. When I manually pull the filament, the end is flattened over and bent into a hook shape. Does anyone know how to fix this?

RE: MMU2s Single Unload Fails

I have the same problem. I have had since I got my MMU2S. I did get on to Prusa support about it, but only got as far as getting confirmation that ramming settings in the slicer have no effect on single colour prints - so all the typical diagnostic stuff about fine tuning tips can't be applied. You're at the mercy of the firmware's unload routine, which does not know what kind of filament you're using, and cannot be tuned. This generally produces poor tips in my experience - either with long hairy tails, or short stubby wings. Both cause problems. I get an unload jam almost every time with Prusament PLA Vanilla. The jam location varies, but is typically at the extruder end, somewhere in the path between the Bondtech and the PTFE tube leading to the MMU selector. The one saving grace on the horizon in that we might get some kind of MMU bypass mode in firmware 3.10. Note that I have tried many things in case it was a hardware issue, but none have worked: new PTFE inside hot end, check all printed parts in filament path for manufacturing defects/obstructions, double/triple check Bondtech alignment, use 3mm inner diameter PTFE between extruder and selector...

This whole situation is very tedious, and frankly it seems that Prusa have not really given enough love to MMU Single mode. Fundamentally, tuneable material-dependent ramming/unload for single mode prints and indeed for LCD panel triggered unloads is a completely absent feature - so bad tips are basically guaranteed. For those of us who do plenty of single colour prints, installing the MMU2S really makes the printer incredibly unreliable - almost guaranteed to need remedial action on every single (apologies for the pun) print. I've read of other people uninstalling the MMU2S from their printer because of this problem.

RE: MMU2s Single Unload Fails

tg73, Thank you for the thoughtful response and I feel your pain. My experience is almost identical to yours. However, my problems are only with PLA. PETG seems to unload without issue.

I have been working with Prusa support as well. They first had me adjust nozzle temperature down and unloading speed up. No change. They are now recommending that I change the hotend ptfe tube because they suspect that excessive friction is causing the misshaped tips and subsequent unload problem. I don't think this will help because I have changed this ptfe tube on multiple occasions with no effect. I have even tried drilling them out to increase the ID.

It seems like we are not the first to tread this ground. Check out this out:

I am experimenting with the filament specific end gcode modifications now to see if I can replicate the portion of MMU2S unload sequence that impacts the shape of the filament tip as the print finishes. The code provided in the post seems to have helped some, but has not completely eliminated the issue. My next step is to slice a single color file in both single and MMU modes and start comparing.

RE: MMU2s Single Unload Fails

It's pretty common issue which is happening during small prints or very slow last layers. The pressure in the nozzle is building up and the unload procedure is happening too fast. Causing the filament tip being too thick. I can recommend to adjust the unload gcode in your profile if it's causing too much trouble.

Possible solution is to wait a little bit before pulling the filament out or make some dribbling move to form the filament tip.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: MMU2s Single Unload Fails

@nikolai-r

nikolai, thanks for the input. In my case, it is happening for prints of all sizes and using the default speed for the last layer. The end of my filament is not really too thick, but has a big hook that catches during unloading. Mine looks exactly like the pictures in the link I provided in my previous post. Do you have any specific recommendations for gcode modifications that I can make?

RE: MMU2s Single Unload Fails

I have an MMU2S and (knock-on-wood) single- and multi-filament work just fine with all default settings. Perfect tips in either case. You guys sound very experienced so I won't ask if you're using all non-mod parts and the latest firmware (for both the printer and MMU2s) and Prusa slicer.

Apologies ahead of time for the long-winded comment.

Just out of curiosity, have you changed between PETG and PLA before having your issues? If so, have you tried changing the nozzle to a new one? It sounds like you've tried everything else. I ask because I always wondered, what happens to the residual PETG that is left behind in the nozzle and stays relatively solid when switching to PLA? When you unload any filament it leave behind some amount of filament (the nozzle holds about 50mm**3 - not all of that comes out), and leaving behind PETG (or ABS) inside the nozzle when going to PLA (a much lower temp) seems like it might build up inside the nozzle and affect the flow or tip retraction shape. Really if those default slicer parameters worked initially for you they should continue to work unless there's a physical hardware issue.

I do switch between the two filaments (PLA and PETG), which as you know have very different temperature settings (you could have a delta of 90c). After a while of everything working perfectly I did one day randomly experience some serious with PETG - it was the first time I ever had any issue. I just happened to be watching (first layer) and filament stopped coming out for about 5 seconds like it was plugged, and then BAM a large blob was ejected like a dam burst. It was obvious the nozzle was plugged and finally the pressure forced it out. When I stuck a tiny needle up into the heated (240c) nozzle it was very thick and viscous; I worked the needle in and out which had quite a resistance, drawing out filament with each pull until it got soft and it felt more molten inside the nozzle. I then ran a PETG test print at the upper end (260) for a couple of hours and afterwards starting printing the Lack components (which is a LOT of printing - 30-40 hours worth) and never had an issue again.

So - just wild speculation...knowing that filament is always left behind during a change, I was thinking perhaps when I went from PETG to PLA the residual PETG in the nozzle just cooked at low PLA temps for hours and hours of printing, the PLA never clearing it out because it's stuck to the nozzle wall and even its composition may have changed with all the hours of cooking at below glass temp. With the PETG "cooked/burnt" along the nozzle wall or a tiny blob in there perhaps it could even affect the tip shape during retraction. When I switched back to PETG this "cooked" PETG stuck to the nozzle, affected the flow and viscosity and cause my plugging and blobbing. Sticking the needle in the nozzle to release it and then running the printer at the high end of PETG temp for hours finally cleared it out.

Crazy theory I know - but 1) my MK3s + MMU2s, fully stock, is proof that mechanically it can work fine with the defualt PRUSA settings and 2) it sounds like you have tried everything except changing the nozzle (or at least heating it way up to PETG or ABS temps and using a needle to clean out the nozzle). It might be worth a shot.

RE: MMU2s Single Unload Fails

@nikolai-r @john-w80 @steve-e3

As per john-w80, I find that this happens with all manner of single mode prints, regardless of size etc. Even doing a load followed by an unload from the LCD menu leads to jams (so no print involved at all). As it happens, I have been almost exclusively using PLA. I suspect that the issue might be material-dependent - my (admittedly-hazy) memory suggests that the problem is less apparent with PETG.

The idea of manually adding ramming code to MMU Single prints is an idea, but will have no effect on LCD panel unloads, which are sometimes necessary if printing was interrupted and cannot be automatically resumed, or if there's some other jam. Also, why does PrusaSlicer not add the relevant GCODE itself?

A while back, before getting the MMU2S I did experience the joy of certain retraction patterns and low flow leading to PLA filament "baking" in the hot end - I actually had to strip the hot end down to clear the jam in that case (and replace the PFTE). But that was an isolated issue. Some people attribute that problem (or part of it) to the custom Prusa heatbreak with the little step inside, so for a while I switched to a "pure" e3d titanium heatbreak - again, note that this was before MMU, and I switched back to the Prusa heatbreak when I installed the MMU, as that's what the step is for.

I also do cold pulls if I suspect cross-contamination or as needed to clear any possible gradual build up of crud.

Overnight I had an additional realisation: one thing that I've not seen discussed around this problem is friction in the feed path. By that, I mean the fiction on the filament from when it leaves the spool to when it reaches the hot end. This is also one area where different users may have very different set ups. I simply don't have the space to place the official Prusa spool holders on the worktop behind the printer, so I have my spools above the printer in something like an IKEA LACK setup. This does introduce additional bends in the PTFE, which I know is not ideal. I'm guessing that increased friction could affect how the filament actually moves during the fast ramming/tip preparation moves (be that extrusion or retraction direction). steve-e3 - you, the lucky keeper of the mystical unicorn that is capable of reliable MMU Single prints - what setup do you have?

I wonder if a test routine could be created that evaluates filament drag - something similar to the X & Y axis belt tension number, but on the extruder?

RE: MMU2s Single Unload Fails

steve-e3, tg73,

Thank you both for taking the time to communicate your ideas and experiences. Here is what I can add regarding the points you both make.

1. Printer configuration. My setup is not stock. I have switched to a modified selector block to improve the design of the filament path and MMU rear ptfe holder that uses Festo type fittings. I have also changed the ptfe from the selector block to the extruder to 3mm ID. These changes have resulted in very reliable tool changes and I don't feel they have impact on the problem at hand.

2. I constantly switch back and forth between PLA and PETG and the issue steve-e3 describes is very logical and had never occurred to me. By coincidence, I just changed my nozzle (along with the entire hot end) because I stripped the threads in the heater block. Lesson learned the hard way there. My first print after putting everything back together was PLA. I believe that the first unload failed but can't be sure because it has become the norm and I don't remember. I wish I had been paying more attention. The idea of clearing the PETG is very good and certainly warrants some investigation.

3. I dispense filament using this setup ( https://www.thingiverse.com/thing:3947469 ). It works incredibly well and there is very little friction coming out of the box. I then go directly to the MMU. I have verified that there is little to no friction in the MMU by pulling filament back and forth from the outlet side. I then use 3mm id tube down to the extruder. When previously troubleshooting this problem, I even drilled out the hot end ptfe slightly to see if that would help (which it didn't). Bottom line, I don't think I can reduce friction any further within the constraints of the current design.

To tg73's point, the system should handle these simple unloads gracefully regardless of whether they are done as a part of normal print execution or manually using the LCD panel.

RE: MMU2s Single Unload Fails

So as a general statement, the vast majority of people with MMU issues - at least that I have helped with on these forums - have modded their setup. For some I understand why they did it - as it relates to their physical setup, e.g. Lack stand. But most are modifications to the MMU itself or the extruder itself which are simply not needed and just introduce more variables for failure. Realize as soon as you change any of these you no longer are using a Prusa-proven design. The mental starting point for debugging an MK3s+MMU2s is realizing that if all components are working properly (including using the latest firmware and software with default settings) it works just fine. Period. No ramming speed adjustments, no different FINDA housing from Thingiverse, no custom gcode, etc. The design has been proven through thousands of hours of printing at Prusa, and tens of thousands of hours with owners of working systems. I'm proof. My MK2 has run perfectly for 4 years, no changes to the hardware or slicer settings. It's insanely reliable. My MK3 - 2 years with no changes, default settings. It's insanely reliable. My Mini - 4 months no issues. My MMU2s - so far 3 months and it works perfectly. Yes it is possible that someone may get a bad component or improperly assembled machine from Prusa, or that a slight tweak in the slicer is needed, but that is the edge case, not the norm. It's a machine; it works correctly if the pieces are working correctly. Period.

Almost always someone mods their machine hoping it corrects what is in reality some underlying problem, in effect band-aiding it. The band-aid may work for a while, maybe a long while, but it is covering up some other (usually vexing) issue that will just cause an issue down the road.

"I have switched to a modified selector block to improve the design of the filament path and MMU rear ptfe holder that uses Festo type fittings. I have also changed the ptfe from the selector block to the extruder to 3mm ID."

There is simply no need to do this. Perhaps you thought this was preemptive or it might have helped cover up what is in reality some other issue - but realize these changes are totally unneeded for a properly operating machine. There is no reason my (and thousands of other) stock MK3s+MMU2s printers are working perfectly right now and yours is not except for something that is not working correctly in either your extruder or MMU2s or the mods you made. If you are using modded components and changing slicer settings and adding custom gcode you are taking a left-hand turn down a dead-end.

At this point someone usually responds about how many complaints there are about the MMU2s on the forum, which really isn't a metric for anything. (People go to the forum when they have an issue, not when life is good). What struck me as funny, and sad, is reading the comments in the online assembly instructions for the MMU; here are some of my favorite quotes which explain a lot of the issues that people have:

"I tightened mine too much as I didn’t read all the way down the instructions before proceeding. I cracked it and tried to glue it, but I believe the crack was exacerbated by tightening the two tension spring screws down too far on the idler assembly. Because the screws were loose on the extruder motor shaft due to the crack, the idler was shifting off the filament and not allowing the gears to grab it sufficiently to either load or eject properly" [Using a cracked/glued part instead of printing a new one]

"M3x10 screws didnt work for me for the top two holes, I had to use M3x14 screws for them." [Didn't realize the nuts were missing so wrong screws used instead to compensate, may interfere with other parts and will again use the wrong screws later where it requires the now missing M3x14 screws]

"I flared the ptfe tubes behind the selector on all 2 parts and now it's much better. I don't understand why you insist on saying that they are flared only on the outside" [Absolutely no need to flare the PTFE tubes...modding the design before it's even working and not even knowing why, discounts the engineering behind the design]

"After some jams during assembly I also had to use superglue." [No directions anywhere ever call for gluing components together]

"The thermistor I got is a cartridge with a short “pigtail” connector" [Using after-market non-Prusa parts and complaining it doesn't have the correct connector.]

There's plenty more but you get the point.

So - some things that you have probably already checked out but for completeness:

Is the FINDA and IR sensor sensing filament correctly and communicating? (They need to be perfectly calibrated and work together). Are all Bondtech gears (in the MMU2S and extruder) perfectly aligned with the filament? When you retract the filament completely out are there any unusual marks from EITHER set of bondtech gears (near the end and about 9" down)? Do you have the correct filament tension on the extruder? Have you tried replacing the nozzle with a new one? Does the filament travel freely (by hand) from the buffer, through the MMU2S and down to the nozzle? Are you using quality filament at the correct temperature that is "fresh". (Note even PLA temps vary dramatically, e.g. Matchbox is 180-210 and Prusament is 215). Have you tried all your single filament tests with each of the 5 different MMU2s ports?

Are you using default Prusaslicer settings. (My advice - remove Prusaslicer and any residual directories and re-install from scratch). You should be debugging with newly loaded software, default settings and PLA.

Have you done a reset-to-factory on the MK3s? This deletes all stored machine information. (I have seen users that after doing this, and the step above, fixed their issues).

You mentioned your filament is easily fed down to the extruder. Have you skipped your modded filament path, fed the MMU2s directly (no Festo fittings or PTFE)? If this doesn't work you have an issue with software, firmware and/or an extruder component(s), not the MMU.

"To tg73's point, the system should handle these simple unloads gracefully regardless of whether they are done as a part of normal print execution or manually using the LCD panel."

Yes, exactly!

After trying all of the above and it still not working, you may be in a position where you need to keep stripping your machine down more and more until you find the issue. But if you essentially re-build your machine from the ground up you will find the problem and will have a perfectly working machine.

RE: MMU2s Single Unload Fails

steve-e3, Wow! Thank you for the detailed response. I really appreciate the time that you spent putting your thoughts together. In reading your post, it seems like you have the impression that I believe the problem lies with the MMU. This is not the case. The printer works perfectly for both multi color prints and single color prints using PETG.

I will attempt to answer you points questions in turn.

Mods to the MMU2s: These mods were not preemptive. I did them to address specific problems that I was having when trying to get reliable tool changes for multi color prints. I was having two problems. First, filament was getting hung when loading into the MMU during tool changes. Second, the design of the selector did not hold the cutting blade securely in place. I recognized that a smooth filament inlet path required precise adjustment of the ptfe tubes with the stock components. I just felt that an improved selector block design would would help and it did. The ptfe tube holder has really improved the inlet path. Tool changes are rock solid now.

Is the FINDA and IR sensor sensing filament correctly and communicating? Yes, I have tested both and they are working.

Are all Bondtech gears (in the MMU2S and extruder) perfectly aligned with the filament? Yes. Perfectly.

When you retract the filament completely out are there any unusual marks from EITHER set of bondtech gears (near the end and about 9" down)? There are very light bondtech marks from the extruder. I am running with the tensioning screw head just slightly out from the extruder. The only time the MMU gears leave a mark is during the failed unload attempt.

Do you have the correct filament tension on the extruder? Yes, as mentioned above, the screw head is just slightly out from the extruder body. I have experimented with different positions as well.

Have you tried replacing the nozzle with a new one? Yes.

Does the filament travel freely (by hand) from the buffer, through the MMU2S and down to the nozzle? Yes, very freely. Also, I don't use a buffer for single color prints to reduce friction and system complexity.

Are you using quality filament at the correct temperature that is "fresh". Yes, the unload fails with Prusament PLA, MatterHackers PRO Series PLA, and Push Plastic PLA. All are fresh (and kept in dry boxes with desiccant) and temperature settings are customized to the manufacturers recommendations.

Have you tried all your single filament tests with each of the 5 different MMU2s ports? Yes. However, I truly believe that this is not related to the MMU. When it happens, the MMU bondtechs grind and grind to pull the filament. If you turn the machine off and cut the filament at the MMU bondtech, it comes out in both directions easily. If you remove the MMU festo connector and pull the filament up, it wont come out. If you release the tension on the extruder bondtech and pull, the filament comes out and has a big hook on the end.

Are you using default Prusaslicer settings. For the most part yes. I only added the custom end print gcode in an attempt to correct the unload failures. Understand your recommendation to reinstall.

Have you done a reset-to-factory on the MK3s? No. I am happy to try it though.

You mentioned your filament is easily fed down to the extruder. Have you skipped your modded filament path, fed the MMU2s directly (no Festo fittings or PTFE)? No. Did you mean fed directly to the extruder? Again, I don't believe the root cause is the MMU. PETG unloads without issue every time.

RE: MMU2s Single Unload Fails

@steve-e3 - I'm with you when it comes to component-level modifications. Pre-MMU, I ran for a while with Skelestruder. It was a fun experiment. But I learned that even if you think the Prusa design is not 100% optimal, it is typically reliable, and it is actually supported - unlike a bunch of heavy mods that maybe (maybe) eek a tiny improvment in some area. Anyhow, my MMU2s is stock (apart from the recent trial of 3mm ID PTFE, which I've reverted), and was very carefully assembled, following the instructions very carefully. I've just checked all the selector gear alignments and path resistance, made a couple of minor tweaks to hobbed gear alignment and loosened the rear PTFE cover screws at one end a bit. And then I bypassed my on-top filament solution and tried feeding some filament with essentially no added resistance - just the stock PTFE parts that come with MMU2s. And so far, touch wood, I'm getting decent tips and no unload jams. As I noted in my previous comment, I think that excessive friction due to unavoidable deviation from the Prusa-spools-behind-printer setup is likely a common cause of all manner of problems. Firmware analysis of load on the pulley motor in MMU2 might be very helpful in warning people of this situation. I'll try to improve my spool set up, continue testing, and see how it goes.

RE: MMU2s Single Unload Fails

@tg73

tg73, great to hear that you may have solved your problem and friction might have been the culprit. Here is a picture of my setup configured for single color prints. Friction may be my problem but I don't think it is between the spool and MMU.

RE: MMU2s Single Unload Fails

You are very correct in saying excessive friction is a common cause of failure. Many people assume they're building a roller coaster with twists and turns and long lengths with no respect to the friction involved. Note people have noted the E-Axis stepper running cooler after eliminating those paths - if you have a temp gun you may want to take measurements.

BTW a 3mm PTFE doesn't buy you anything friction-wise; people usually go to that because they can't solve the blobby tip issue and go to larger PTFE as a band-aid, again not resolving the issue. The biggest factors for friction are 1) the number and radius of the turns, and 2) the total length of those turns. If you think about it oversize tubes don't change the amount of contact between the tube and filament in a turn.

Good luck.

RE: MMU2s Single Unload Fails

steve-e3,

I have gone back and read your other posts to this forum and now have a better understanding of your position, specifically regarding the MMU and how to make it work properly. Although I am hesitant to do so, I think it would benefit the Prusa community if I provided my opinion on the overall situation. You make many fantastic points, but I see things a little differently.

I believe it might be helpful for you to understand my background and how I have gotten to this point. I have been a practicing engineer for my entire adult life. I spent a career in Hyman Rickover's nuclear navy and have been genetically programmed for absolute procedural compliance (right to the point that is just doesn't make sense). I also completely believe in determining and correcting the root cause for any failure. For the last 16 years, my professional attention has been strongly focused on System reliability and how it is affected by individual Sub-system reliability. On the 3D printing side, I started operating the stock MK3S in early 2019. Although not that long from a chronological perspective, my son and I operate a 3D printing service and this printer has been operating 24/7 for a good bit of this period in a stock configuration with zero issues. We installed the MMU a month or so ago.

After installing the MMU, my initial efforts were to get the system to work reliably in multi-material mode in the stock configuration and I was fairly successful. For this effort, I only had two problems. First, the cutting blade kept coming loose. Second, I would get an occasional hang during tool changes. I agree with you completely that I could have solved the filament hangs by continuing to adjust the ptfe holder. However, I felt that the improved design using the festo fittings would address the issue with low risk to negative impact to overall system performance. In addition, I think we can all agree that the design of the selector block with respect to how it holds the blade could be improved. My opinion only, but I feel that these changes significantly improved system reliability and have no impact on my problem that started this thread. The system operated very well in both single and multi material modes using both PETG and PLA for some time.

Then I started having the problem with unload failures in single mode with PLA. To attempt to address this problem, I reached out to Prusa support and this forum simultaneously. My actions at this point attempted to address both the root cause and improve reliability. First, I replaced the ptfe between the selector and extruder with 3mm ID. This was an attempt to reduce path friction which I viewed as a potential root cause (we could have an engineering based debate on whether this reduces friction) and an effort to improve system reliability. I believe that this is where we diverge in our philosophy.

I agree that this is a machine with sufficient design and testing behind it. That's why I bought it. It will work as designed if properly manufactured, assembled, and operated. However, it has many critical parts that are produced on 3D printers with tolerance inconsistencies. In addition, this is a reasonably complex machine with a lot of coordinated moving parts that can become misaligned or mis-timed. These two factors tend to reduce system reliability. I do not agree with your primary assertion that every system will always work if assembled properly. Although there are a bunch of people out there like the ones you describe in your post, I believe there are also a bunch of very disciplined and technically inclined people that are having problems.

My opinion only, but I believe that Prusa could make design improvements to increase system reliability. Believe me, I want nothing more than to run a completely stock system. I just feel that the design should run properly with parts having manufacturing tolerances, slight misalignments, and something short of perfect assembly. If this were the case, I agree with you completely that there would be no reason to install any modified parts other than to allow for individual setups (e.g. Lack) as you assert.

RE: MMU2s Single Unload Fails

@john-w80

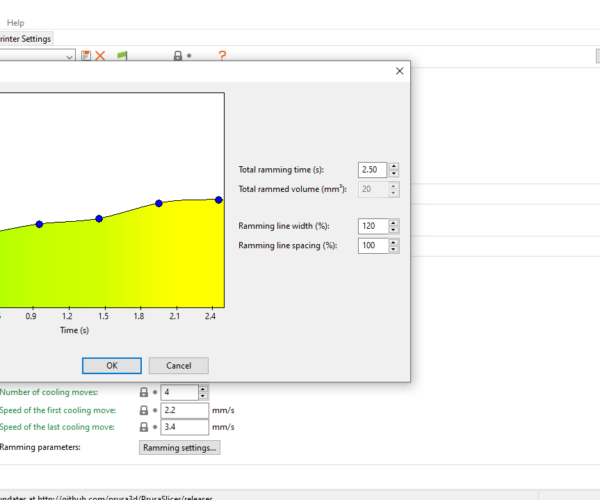

You said that the blade on the MMU2 has fallen off? If that happens, you should 3d print the blade holder and screw it in really tight. I've had issues where the printer has a hard time unloading but after tweaking some settings, I've never had the issue again. Yes, Prusa could do some improvements, but sometimes, the problems are the filament. The 3d printed parts are reliable but sometimes, they have issues too. I had a problem where the blade holder broke too but I 3D printed their new parts for it with the new firmware to cut the ends of the filament and haven't had a problem since. Here are the settings I used for unloading. Let me know how it goes.

I'm a high school student who has had the MK3S MMU2S for a year and have had a lot of successful prints. I try to help as much as I can.

RE: MMU2s Single Unload Fails

If your switching from PETG and PLA, you should sometimes do a cold pull. PLA is good at grabbing stuff inside your extruder and it might be grabbing some excess PETG material. If that is the case, it's not a printer's fault but the filament/users fault for not cleaning the extruder between filament type change.

I'm a high school student who has had the MK3S MMU2S for a year and have had a lot of successful prints. I try to help as much as I can.

RE: MMU2s Single Unload Fails

Wow, this is a pretty cool thread with a multitude of experiences along with the numerous problems that the MMU has inflicted upon us.

I fervently agree that 3mm ID tubing only masks the problem, proper alignment and functioning of this unit don't require using larger diameter tubing. Dialing in the filament fixes the filament end problem which is the general reason for unloading problems. This unit when correctly aligned will almost pull the printer over is one is holding the reel while feeding the filament through the MMU. Just remove for a moment the FINDA probe and initiate a filament load. If the unit doesn't almost pull itself over, then the gears may be dirty or misaligned.

That said, my MMU did not come to me with great quality assurance, although I had no idea what was wrong until I had to dig into the unit itself and not this forum, almost all of the suggestions were erroneous covering up for other underlying discrepancies.

This unit has three major parts that must be manufactured following very tight tolerances and verification procedures. The idler barrel had a minor layer shift caused by some sort of temperature changes during the manufacture. I would endeavor that there was probably a filament change during production. I have no idea if all of the parts are produced on the same bed, but the selector body suffered a similar discrepancy at around the same level. These are very critical parts involved in the proper functionality of the unit. The idler barrel caused a wobble that changed the timing position of the idler bearings on the pully gears. The selector body misaligned the selector rods limiting the movement of the selector, which at times would cause the unit to incorrectly determine the starting position of the selector. Finally the selector itself, I lost the knife on the first use of the MMU, it cut into the body itself. The revised selector seems to have fixed that, but after printing a new selector the filament didn't feed past the festo. I did, however, use a thingiverse selector that apparently, by the author, substantially corrected the alignment of the filament path through the selector. A magnet is in the sensor assembly now which I can only say that the filament doesn't get stuck at the festo. The revision with the blade seems to work as well. It's working now.

I agree that a stock system is generally the best way to go and modifications should be limited to those required to meet a specific need or application. All machines are subject to periodic modifications or upgrades. If the unit had arrived as advertised I would have never had the necessity to learn the operational requirements and theory. It's nice to learn new things, even at my age. However, the cost in time and materials of a unit that should have operated correctly from day one is not justifiable. How many units are there out in the wild where the user has given up having now a new bookend or doorstop in consequence?

There are two quick verification tests that the user could do while building the kit.

1. When aligning the idler body, roll the barrel back and forth observing the mounting area of the idler motor. If this wobbles there is a defective part pushing the barrel out of alignment. The consequences of a misaligned barrel present themselves with numerous random symptoms.

2. When building the selector body, the selector carriage should not present any binding, this part should be free of any resistance. The consequences are similar to others but generally cause the selector to not line up with the filament path.

With the rest of the printer, I have done a couple of minor modifications to the system. The most common is the replacement of the printer shroud, the original shroud got caught up in a monster blob and I simply printed one from the stock set of stl models at the git hub. Even as such I had a lot of trouble getting a good overhang when printing due to nozzle cooling problems. I tried several from thingiverse with varied results until I tried a shroud from RHD, who posts here by the way. The shroud has better stability than the stock one that had a tendency to sag a little to the right of the nozzle. Finally, I added the nylock modification, prior to this I had a .3 mm variance on the bed which the 7 point bed calibration didn't quite correct due to the disparity of the readings. I am content with a 0.02 mm variance which allows for less firmware compensation.

One major factor that must be taken into consideration is that this is an Opensource product based on the RepRap model which means that improvements come from makers, just like all of us. Product improvement comes from the Opensource model where everyone who wants to improve a specific facet of the product has the tools to do so since the model or software is open for all. This gives access to the entire world an opportunity to fix an annoying problem using innovative ideas. Prior to Prusa's adoption of a discrepancy of the current model they wait and see what is being adopted by their users. Then they run it through their process' to publish a revision. That said I've been a fervent supporter of Opensource solutions since the first set of downloadable diskettes that Linus Torvalds placed on the Internet of the very first POSIX Linux kernel.

Our printers from Prusa Research originate from a business model that appears to be linked to Opensource. By mass-producing these printers, they are able to include high-quality parts economically. This also means that if one wants a higher quality component, they can pay for it, although this takes it away from a stock model. Their, Prusa's, improvements that they engineer in the model get incorporated into the mainstream for anyone to use. I believe in freedom of choice and that I should be able to own my machines with the ability to modify them as I wish. This is something that I did not have with my previous printer having to send it back to the factory every time the unit failed. With this printer when it requires maintenance or modification I can do that. Any changes that I perform should increase the reliability and if not, I can always fall back to the previous model.

Of course, nowadays one cannot even get two cents in change; however, here's mine.

Best Regards,

Phil

Stay safe and healthy, Phil

RE: MMU2s Single Unload Fails

@john-w80

Regarding 3mm ID PTFE between the selector and extruder: my experience is that freshly hand–cut filament (eg, after a jam) can catch on the way into the extruder, I assume because the filament is not guided so centrally as with 2mm ID. It's ok with the relatively rounded tip created during an unload, but the sharp point of an angled cut made by a human can catch. Wiggling the PTFE as the filament is driven into the extruded can help. Regardless, I've reverted to stock Prusa PTFE and am currently experiencing success (see my previous posts in this thread).

Regarding the blade falling off: according to Prusa, the blade was inactive prior to firmware 3.9.0. It is now active, and they have improved the blade-related printed parts. I've not been able to find any clear documentation about when tip cutting is performed, and what's supposed to happen to the trimmings. I did see some mention of the tip being cut after a number of failed load attempts, but I can't find where I saw that now. See:

https://blog.prusaprinters.org/firmware-3-9-0-out-now-info-about-new-printers-and-more-news_36178/

(see paragraph titled "MMU2S Selector Blade Activated")

https://github.com/prusa3d/Original-Prusa-i3/tree/MMU2/STL

(see parts with the comment "Improved blade holder")

RE: MMU2s Single Unload Fails

@pcweber

Thanks for your interesting and useful comment. The suggested verification tests look particularly wise. Regarding the pulling power of the hobbed gears/Bondtech: I would suggest that one aspect is performance at modest constant speed, which your "pulls itself over" demonstration would show. Another aspect is performance of rapid sequences of short high-speed moves, such as during tip preparation. Instinctively, I might expect that increased friction in the filament path might adversely affect these moves, where static friction (as each move starts with quite aggressive acceleration) and dynamic friction (due to high speed) could be significant factors. This could explain why I have had much improved tips where the only change was reducing friction in the filament path. Notably, I should note that tips produced with LCD-initiated load/unload are now much improved, and this has nothing to do with dialling in any particular filament via slicer settings, as no generated GCODE is involved.

RE: MMU2s Single Unload Fails

All great ideas and feedback, agree with most of the above. Some other thoughts:

- Agreed a handful of the tolerances are very critical, but also that the bulk of them on any Prusa kit really don't matter. The MMU probably has more of the important tolerances than any of their printers. Things like shafts that need to smoothly rotate, bearings need to be properly set for rotation, mating surfaces of filament paths need to be aligned and smooth, etc.

- Related to the above all parts (for any Prusa kit) during assembly should be dry fitted and tested before the next step. The comments in the online assembly manual are invaluable in this regard. Simple techniques - all holes should be cleaned out with drill bits, cutouts should be cleaned with an exacto knife, filament threads removed, etc. (BTW regarding the knife holder, I specifically recall my blade not fitting quite exactly perfect and spending a few minutes, around midnight I think, cleaning it out until it held it square. Again there was a comment in the assembly guide from a user that assembled it wrong, broke it on the first selector movement and had to disassemble and backtrack to this step.)

- Also - probably a rarer occurrence but applicable in my case because of my delay in building the MMU, always check the Prusa Github site for upgraded components. Specifically for me I paused my assembly and printed the newer "mmu2-front-PTFE-holder" and "mmu2-selector" (fyi the latter which specifically has the comment "improved blade holder"). (There was also a tweak to the MK3s extruder body which I honestly couldn't tell the difference from the shipped part but I printed it anyway).

More specifically for @john-w80, yes after all this I tend to agree with you this is probably not an MMU issue. You can essentially eliminate the MMU as a suspect by removing the PTFE tubes on either side of it and hand-feeding the filament through the MMU and into the extruder but it sounds like you can pretty much rule this out given your debugging.

So....your extruder is malfunctioning.

So even though this thread is in the MMU forum let's rewind to the very beginning: "When I manually pull the filament, the end is flattened over and bent into a hook shape". Do you have a picture of the tip? Or in your previous post that links to a related thread (LINK) with pics of several tips, is the only tip that is in a hook (the orange filament) representative of your tip? (And do you not suffer from the other shaped tips?)

"I am running with the tensioning screw head just slightly out from the extruder": This is probably fine but just note that the instructions are that the screw head should be flush or slightly under (more tight). Of course if it's slipping you will have issues. I know you mentioned you have played with the tension. (No longer relevant for this thread but where people have modded the buffer and inadvertently changed the friction of the path back to the buffer - the poor extruder during all those quick retraction movements has to push all that filament through that higher friction path which can cause issues).

"The printer works perfectly for both multi color prints and single color prints using PETG". So you ONLY have this issue with PLA, PETG prints fine no issues? To me this is the biggest clue - either something to do with temperature, residual filament in the hotend, or a very strange software/slicer issue.

Have you completely removed and then reloaded the slicer?

And you have replaced the nozzle with a new one and it made no difference?

[Getting deeper into disassembly I know...]

Does the hotend PTFE tube, when removed, looks normal? No deformation?

With the PTFE tube removed is it possible to see or detect any foreign objects in the aluminum heatsink channel?

Is the PTFE tube is being re-inserted in the correct orientation? (LINK)

It is crucial that the PTFE tube be inserted all the way in and properly locked in place, otherwise you may have a number of issues with filament and tips. The link above points this out.

Apologies for a lot of seemingly disconnected questions.