mmu2S filament load fails. Reverses filament when it encounters mmu2S sensor.

I am experiencing an issue with my mk2.5S/mmu2S.

I recently did some maintenance on the extruder. The pulley gears were worn out. My printer has 600+ days of use logged.

After replacing the gears in the extruder, the printer was working fine, so I decided to download the latest firmware package.

I downloaded the latest PrusaSlicer (2.5.0) and installed it on a different PC (just to be sure) and then downloaded: prusa3d_fw_3_11_MK3S_1_0_6_MMU2S and installed: prusa3d_fw_MK25S_3_11_0_4955_RAMB013a_en_cz.hex and prusa3d_fw_MMU2board_1_0_6.hex from that zip file.

Since upgrading the firmware, when loading filament, the filament is drawn into the mmu2S until it reaches the mmu2S sensor, then the pulley driver reverses and withdraws the filament about 20-30mm and stops. Previously, when the printer was working normally, the filament would speed up and continue drawing until the filament reached the extruder.

I monitored the sensor status and I see it changing from 0 to 1, which indicates the sensor is working. If I remove the sensor, the Load filament begins drawing the filament and continues to slowly draw it past the sensor location until I power off. Clearly, the motor is reversing when the sensor is triggered when it should speed up and continue the load. I could not detect any clicks, grinds, or other indication of a bind or obstruction.

I cleaned the mmu2S pulley gears, checked for bad connections, broken wires, and clogged passages. The filament slides smoothly when manually inserted.

Finally, I did a factory reset for both the printer and the mmu2S, and reinstalled the latest firmware again.

I searched the community forum and found these similar descriptions: 'filament loads and immediately unloads' from Andrewpfeil. He got no responses.

'FinDA Probe & Filament not loading MMU2 ' from RedBeard. One response suggested adjusting the sensor. That didn't work.

All 3 motors on the mmu2S seem to be working fine, and all other mmu2S behaviour seems fine (mmu2S buttons operate the selector, roller cam operates, pulley gears rotate, etc.).

Could this be a software glitch? Or maybe the mmu2S circuit board?

Any suggestions would be greatly appreciated.

RE: mmu2S filament load fails. Reverses filament when it encounters mmu2S sensor.

This sounds a bit like the filament sensor tower being out of adjustment.

I found using the LCD Menu, to confirm sensor status, to be a pain,

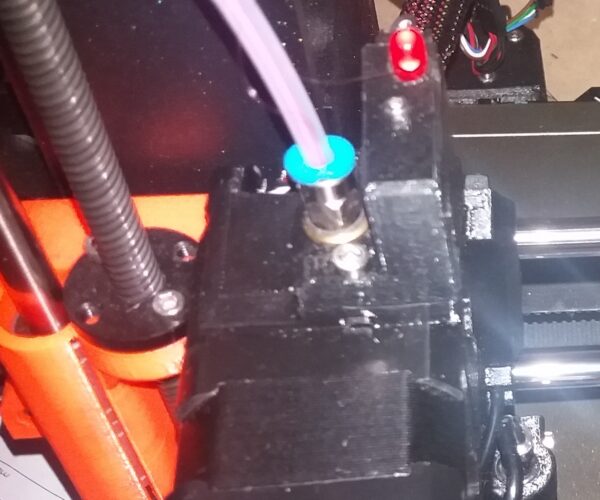

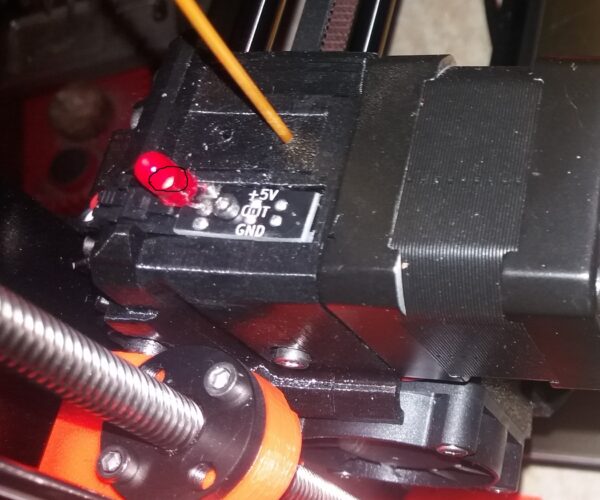

So I fitted a 5volt LED, to my filament sensor, to give immediate indication of status.

I include an image of My Mk3S which shows the location of the LED...

the LED Glows, when the filament is sensed.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: mmu2S filament load fails. Reverses filament when it encounters mmu2S sensor.

Thanks @joantab for the reply. I did test the sensor on the extruder when trying to analyze the problem. I displayed the sensor status on the support menu and slid some filament past the sensors on both the mmu2S and the extruder sensor. Observed the values changing from 0 to 1 quite consistently. I have a spare extruder sensor and will likely implement the led mod as you suggested. It looks like a useful indicator.

Based on your suggestion, are you saying that a loose or imperfect extruder sensor would prevent the mmu2S from completing the load sequence? It just seems to me that the mmu2S sensor being triggered is what causes the filament to reverse, stopping the load sequence long before any filament arrives at the extruder.

RE: mmu2S filament load fails. Reverses filament when it encounters mmu2S sensor.

mmu2 is very fussy, it relies upon both the pinda and the finda for correct operation. rubbish in the finda filament chamber or finda, out of adjustment can also cause feed / load issues

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: mmu2S filament load fails. Reverses filament when it encounters mmu2S sensor.

mmu2 is very fussy, it relies upon both the pinda and the finda for correct operation. rubbish in the finda filament chamber or finda, out of adjustment can also cause feed / load issues

Why would the MMU2 rely on PINDA?

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE:

OOOps. brain failure, well spotted... I actually meant filament sensor and Finda...

the MMU advanced the new filament, notes that it has passed the Finda Check and then feeds until it arrives at the Filament sensor at which point the normal bondtech extruder gears should take over control of the filament feed and the MMU should release the filament drive.

If either the Finda or the Filament sensor are out of adjustment, this sequence can be disrupted. (Reverse bowden tube length can also be a factor) My latest 'Prusa provided reverse bowden tube was an unsatisfactory length, so I changed it... (Can't remember if I shortened it or lengthened it, I suspect I lengthened it, because I changed it, instead of cutting it, and you can't cut it longer 🙂 )

anyway, when I first got the MMU2S (Years ago,,,) I had many failures to load, until I got the filament sensor adjusted...

currently I am not using the absolute stock mmu2S and I understand that Prusa have hinted that they are making adjustments to the MMU design,

when they have a finalised design, I will try that out, and see if I can join the ranks of standard MMU users again...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK