Why the "chimney"?

I'm wondering why it was needed to add that chimney for the MMU2S?

Is it because more distance is needed between triggering of the sensor and reaching the bondtech gears? (slow mmu2 communication)?

In any case I have 2 practical issues with the current implementation:

Firstly it's a bit annoying that you have to unmount it to be able to open the idler door.

Secondly I really don't like how the sensor connector just "sits there" in the air, waiting for something to catch behind it and break it off.

I actually almost did that by accident. Can the next revision at least make sure the entire sensor is encapsulated?

Edit: since this post I found this gem on thingiverse:

It's a redesigned idler door where the lever is mounted via a screw and be "disengaged" so you can open the door without having to disassemble the entire thing

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Why the "chimney"?

The long arm is required to amplify the displacement of about 1mm when the filament feeds through the bond tech gears to about 4mm. The IR sensor probably can't pick up a 1mm displacement due to the size of it. I agree having to remove the door is a pain but the MMU2s is much more reliable the MMU2. That IR sensor makes all the difference when it comes to reliably feeding and ejecting the filament between the MMU and the extruder.

Re: Why the "chimney"?

The long arm is required to amplify the displacement of about 1mm when the filament feeds through the bond tech gears to about 4mm. The IR sensor probably can't pick up a 1mm displacement due to the size of it. I agree having to remove the door is a pain but the MMU2s is much more reliable the MMU2. That IR sensor makes all the difference when it comes to reliably feeding and ejecting the filament between the MMU and the extruder.

The mechanism of the MK3S works with IR as well and uses the internal lever, much less error prone.

No, thinking about it I conclude requirements are simply different:

For the regular MK3S the triggering of the sensor indicates that a filament is about to be inserted and the bondtech's should start spinning.

For the MMU the sensor should be tripped the moment the filament reaches the bondtechs, indicating the MMU can stop feeding.

It makes sense, but I still don't like the connector being so vulnerable.

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Why the "chimney"?

Edit: since this post I found this gem on thingiverse:

It's a redesigned idler door where the lever is mounted via a screw and be "disengaged" so you can open the door without having to disassemble the entire thing

Have you been able to print that? I get gaps on the nut-hole and it is far too weak to hold the nut.

Re: Why the "chimney"?

Have you been able to print that? I get gaps on the nut-hole and it is far too weak to hold the nut.

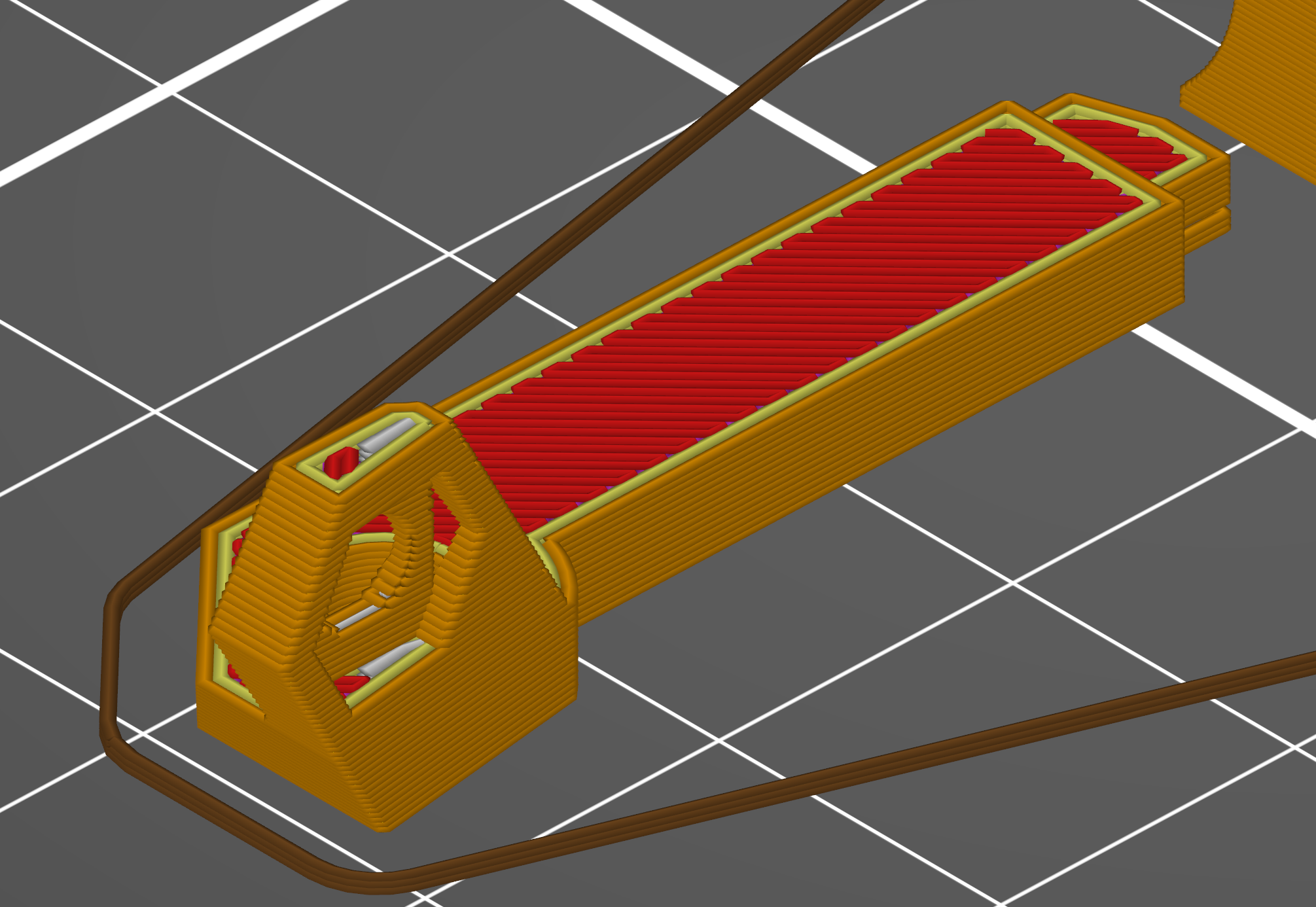

Haven't had time yet but it looks the same here when I slice it.

Saw you already asked on TV... Looks kind of flimsey though

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Why the "chimney"?

Have you been able to print that? I get gaps on the nut-hole and it is far too weak to hold the nut.

Haven't had time yet but it looks the same here when I slice it.

It's mentioned in the comments, creator claims it should work fine with it.

That comment is from me. It's far too fragile when I print it. I was hoping someone else had tried.

Re: Why the "chimney"?

That comment is from me. It's far too fragile when I print it. I was hoping someone else had tried.

Yeah realized it right after I posted it. Hence the change, but you are too fast 😉

Too bad.

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Why the "chimney"?

That's an interesting concept but I don't see how that is that much more convenient. You still have to unbolt the separate arm to open it up as well as the tensioner bolt. You're still removing two bolts in the end and as you pointed out that separate arm is really fragile.

Re: Why the "chimney"?

That's an interesting concept but I don't see how that is that much more convenient. You still have to unbolt the separate arm to open it up as well as the tensioner bolt. You're still removing two bolts in the end and as you pointed out that separate arm is really fragile.

The added value (imo) would be that you don't have to recalibrate the chimney each time. In any case, with some of the material removed from the lever I now have a reliable toggle so I guess that shouldn't pose such an issue anymore.

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Why the "chimney"?

That's an interesting concept but I don't see how that is that much more convenient. You still have to unbolt the separate arm to open it up as well as the tensioner bolt. You're still removing two bolts in the end and as you pointed out that separate arm is really fragile.

It would be easier in that it's a shorter screw in an easier-to-access location. It doesn't hold the nut, though.

Re: Why the "chimney"?

Have you been able to print that? I get gaps on the nut-hole and it is far too weak to hold the nut.

Haven't had time yet but it looks the same here when I slice it.

It's mentioned in the comments, creator claims it should work fine with it.

That comment is from me. It's far too fragile when I print it. I was hoping someone else had tried.

Well, I have, obviously, and it's working well for me. I'll take a look at it this weekend and see if I can make it a bit stronger.

Re: Why the "chimney"?

That's an interesting concept but I don't see how that is that much more convenient. You still have to unbolt the separate arm to open it up as well as the tensioner bolt. You're still removing two bolts in the end and as you pointed out that separate arm is really fragile.

It would be easier in that it's a shorter screw in an easier-to-access location. It doesn't hold the nut, though.

Two other reasons.

• I try and minimise undoing and retightening screws that go into motors. Cross threading a nut is no big deal. Screwing up the thread in a motor is.

• I chucked the little nylon washers back in. Makes it harder to remove the door.

RE: Why the "chimney"?

What I don't understand about this "chimney" ... maybe it's another issue with the parts I got ... but the mounting bracket that comes with this does not seem to match up bolt pattern wise to the top of my extruder, the holes are completely off (MK3 / MMU2) - It's almost like I got sent the wrong parts, and I can't seem to figure it out in the guides. The guides even show a different part on top of the extruder (the threaded brass for the PTFE tube that goes to the MMU2) so ... completely lost as to why I even have the chimney!

RE: Why the "chimney"?

What I don't understand about this "chimney" ... maybe it's another issue with the parts I got ... but the mounting bracket that comes with this does not seem to match up bolt pattern wise to the top of my extruder, the holes are completely off (MK3 / MMU2) - It's almost like I got sent the wrong parts, and I can't seem to figure it out in the guides. The guides even show a different part on top of the extruder (the threaded brass for the PTFE tube that goes to the MMU2) so ... completely lost as to why I even have the chimney!

I'm guessing you haven't updated your extruder body to the Mk3s.