Week 3

We are three weeks into this release and I am amazed on the low volume of finished prints being displayed here. Am I wrong?

Steve

Re: Week 3

http://www.kisslicertalk.com/viewtopic.php?f=15&t=2371&sid=2568829b31643dc1320d35434035d150

🙂

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Week 3

That British Shorthair print is most impressive Peter!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Week 3

That British Shorthair print is most impressive Peter!

Thanks - it's actually a money box, with the coin slot at the back of the collar. We have a British Shorthair with similar colouration 🙂 It's a "paid-for" model by Loubie.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Week 3

We are three weeks into this release and I am amazed on the low volume of finished prints being displayed here. Am I wrong?

Steve

I've had mine running for a week and do not yet have a successful print (focusing just on the 50% sized sheep, two filament).

Re: Week 3

Those are some good prints, but is that from one person that has had it longer than three weeks? Where are the big number of prints from the first owners of the shipped product?

Steve

Re: Week 3

Those are some good prints, but is that from one person that has had it longer than three weeks? Where are the big number of prints from the first owners of the shipped product?

Steve

Absolutely correct, but if you look there are more photos almost every day 🙂

And yes, I totally agree that there is a complete lack of users posting anything about it 🙁

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Week 3

I have the mmu since about 2,5 weeks now and would like to share some prints but as there are still too much problems with load / unload I cannot run any print successfully (keyword missing layers).

There are others with similar issues so probably there are a lot of units not in use at the moment (like mine) or they are still trying to figure out the issue until prusa provide a newer firmware.

Re: Week 3

I have the mmu since about 2,5 weeks now and would like to share some prints but as there are still too much problems with load / unload I cannot run any print successfully (keyword missing layers).

There are others with similar issues so probably there are a lot of units not in use at the moment (like mine) or they are still trying to figure out the issue until prusa provide a newer firmware.

Same here. My MMU2 is sitting idle. I'm afraid to try an ambitious multicolor print for fear of a layer skip the mk3 won't catch, wasting a bunch of filament on the process.

Looking at that clown fish makes sad. I was so close too. During the missing white layer, mk3 was just printing air.

So now all I've done in the past few days is try and tweak ramming settings to work with my various filaments. That and check GitHub every 6 hours for a new firmware.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Week 3

Yes and no word from prusa about that.

Contacted live chat - they told me I should contact them threw mail

Contacted them threw mail - they was not really helpful and I told them that I created a github ticket, after that they just said that they will look into it and I can keep on testing

I have seen lots of guys with the same issue and I checked all my mechanical things several times but I think the issue comes from the firmware (missing extruder sensor, wrong ramming settings and temperatures for prusa filament, etc)

Re: Week 3

Same here. My MMU2 is sitting idle. I'm afraid to try an ambitious multicolor print for fear of a layer skip the mk3 won't catch, wasting a bunch of filament on the process.

Looking at that clown fish makes sad. I was so close too. During the missing white layer, mk3 was just printing air.

So now all I've done in the past few days is try and tweak ramming settings to work with my various filaments. That and check GitHub every 6 hours for a new firmware.

One thing you can do while waiting is measure the diameter of your five gears and rearrange them so the smallest gear is on filament 1.

That's not optimal, but may get you going while waiting for a firmware update that lets you calibrate each gear individually.

Re: Week 3

Checked mine today and all are withing +-0.02mm (as good as I can measure them)

Re: Week 3

New pre release v3.4.1-RC1

https://github.com/prusa3d/Prusa-Firmware/releases/tag/v3.4.1-RC1

Nothing for mmu2 🙁

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Week 3

Yes completely nothing...

Really frustrating, we probably will not get our units working for a while.

Re: Week 3

There may be another temporary work-around:

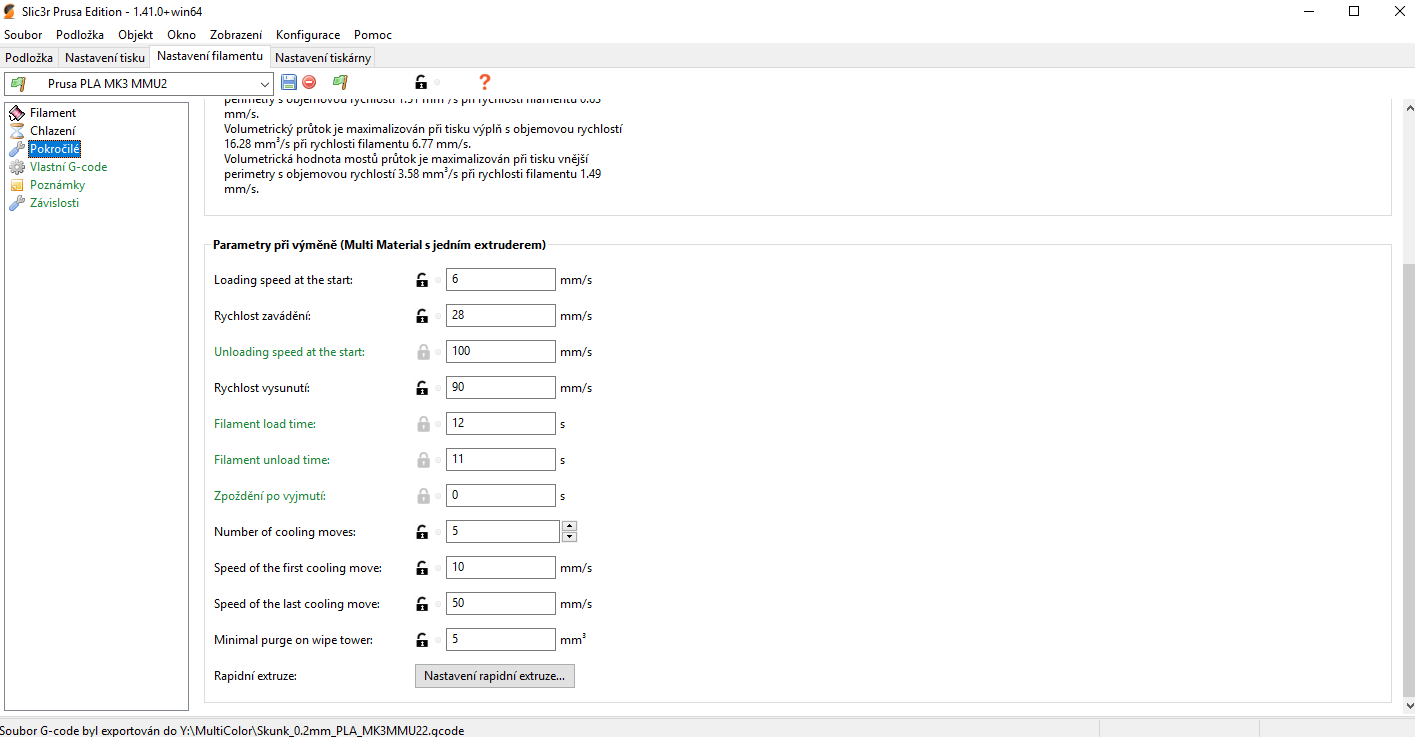

Can you try setting the "Loading speed at start" value to 19 mm/s for all filament, slice a small model and try that. Things should improve slightly. You could also try setting the "Loading speed" to 22 mm/sec for all filaments.

This is an attempt to match the Bondtech speed with the MMU.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Week 3

There's also a couple of other things you can try:

Printer Start G-code - reduce E acceleration to 1000:

M201 E1000

And set the "Unloading speed at the start" (see image on previous post) to 80 mm/s for each filament.

I also play around with the E micro-stepping, setting to 1/8 for ramming and unload then back to 1/32, and E motor currents, setting to 24 for print, 31 for unload and 0 during tool change, with holding currents to 16 and 0 during tool change. However, I would not recommend you consider doing this, unless you really know what you are doing.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Week 3

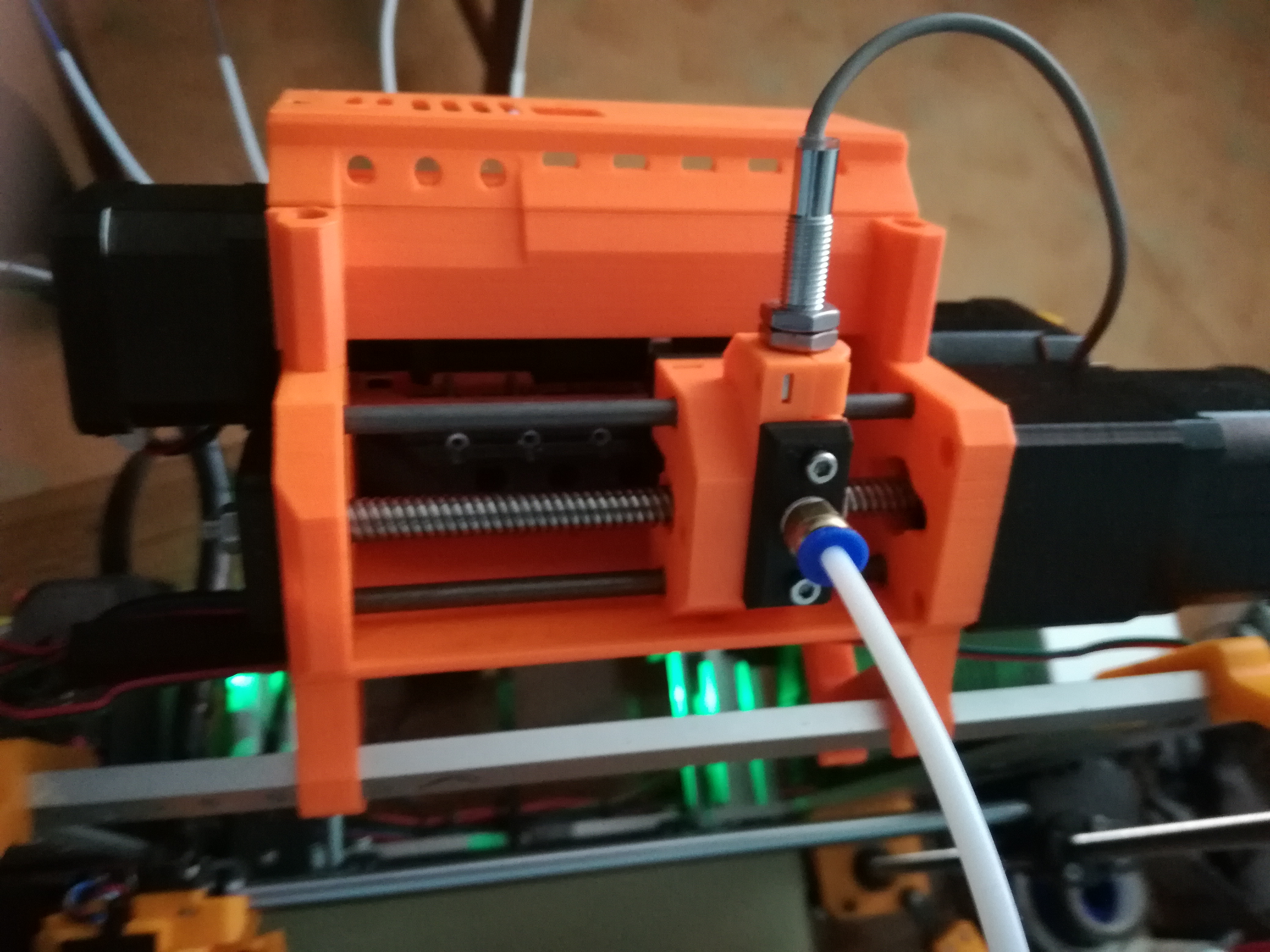

I have mine assembled as of yesterday but haven't tried using it for a few reasons...

1) Not enough time yet

2) I need to come up with a better spool mounting solution for spools in an enclosure with desiccant. Without one, MMU is a non-starter. My garage is far too humid, it turns filament to junk within a week or less.

3) Frankly I'd rather wait a few more weeks and let other people deal with early adopter software/firmware issues. See #1.