RE: Thanks to the Forums

I just started a print and forced a few load errors. I don't get the blob on the purge tower.

When I feed the filament in again at the back of the MMU and press the middle button to re try to load and the right button to resume the print, the filament gets loaded to the extruder and before it starts to extrude the x axis will start moving. It does this like on any normal load.

When I wait longer to get the "MMU needs attention" message, the extruder moves to the back left of the build plate and starts cooling down. When the load error gets fixed the extruder moves back to the purge tower and starts re heating. And starts moving before extruding.

How it is working for me, it really can't make a blob.

I'm trying to figure out what it could be doing or see on the sensors to extrude without moving.

Did you try reloading the firmware? Maybe a glitch that could be fix by a reload.

Have you tried contacting support? Maybe that know about this and know a fix.

RE: Thanks to the Forums

@baklin

I haven't tried reloading the firmware, but that might be a good idea. I got the the MMU with the 1.0.6 firmware so never had to reload it but I'll try that. Can't hurt for sure. I have reloaded the printer's firmware, currently at 3.10.

I did actually email support this morning so we'll where that goes. The blob problem seems to happen after the printer returns to the info screen and it says that the MMU load failed. This is where you'd hit the button and select resume print. It doesn't happen if I notice the failure and catch it just after it moved the extruder and started cooling down. I think it also has to do with if the failure happens because the filament couldn't be retracted vs it couldn't be loaded. I *THINK* it primarily happens if the previously used filament couldn't be retracted and requires it to be manually pulled. I have a single filament going on that printer currently but I'll try reflashing the firmware after.

RE: Thanks to the Forums

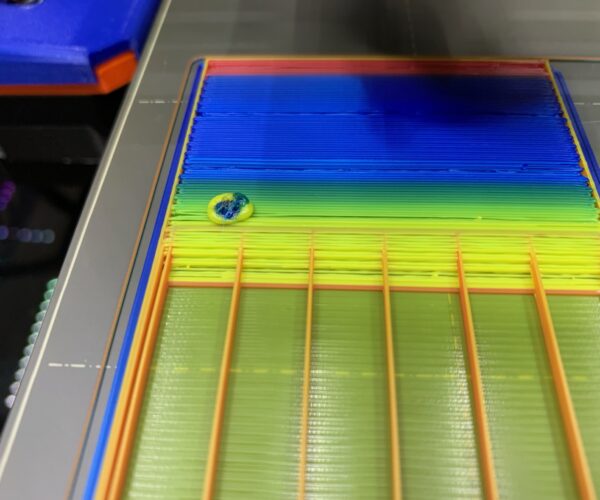

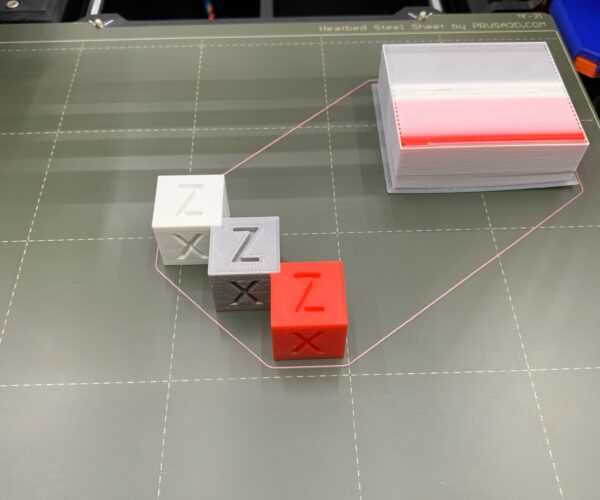

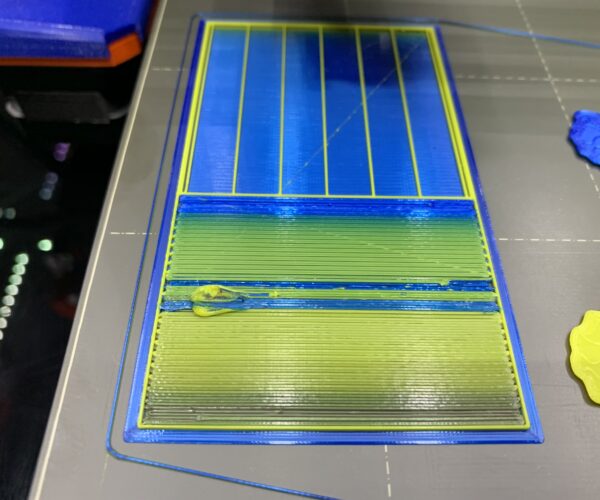

Ok I reflashed 1.0.6 firmware on the MMU. doing a small 7h print with 3 colors to see if anything is improved.

RE: Thanks to the Forums

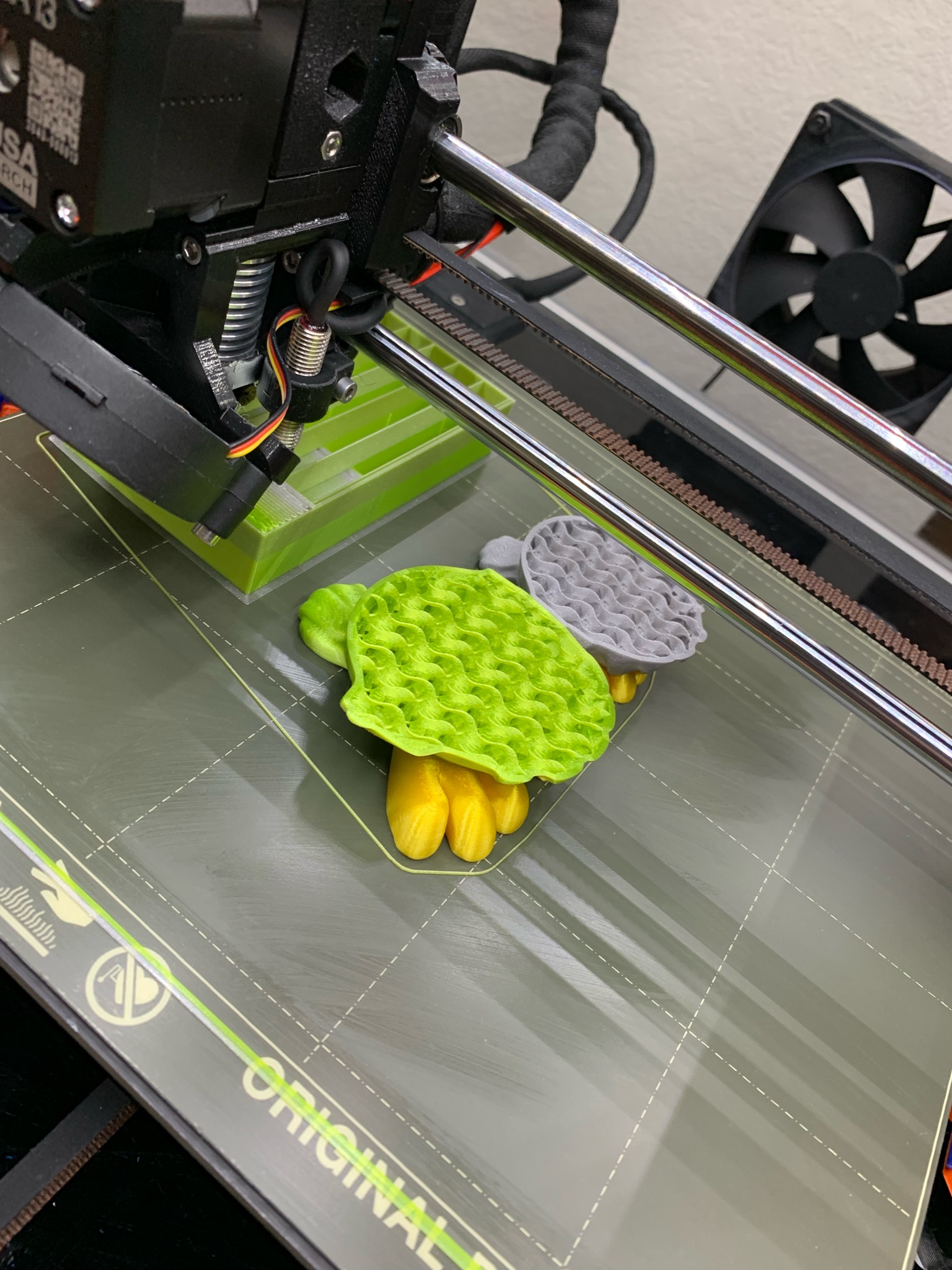

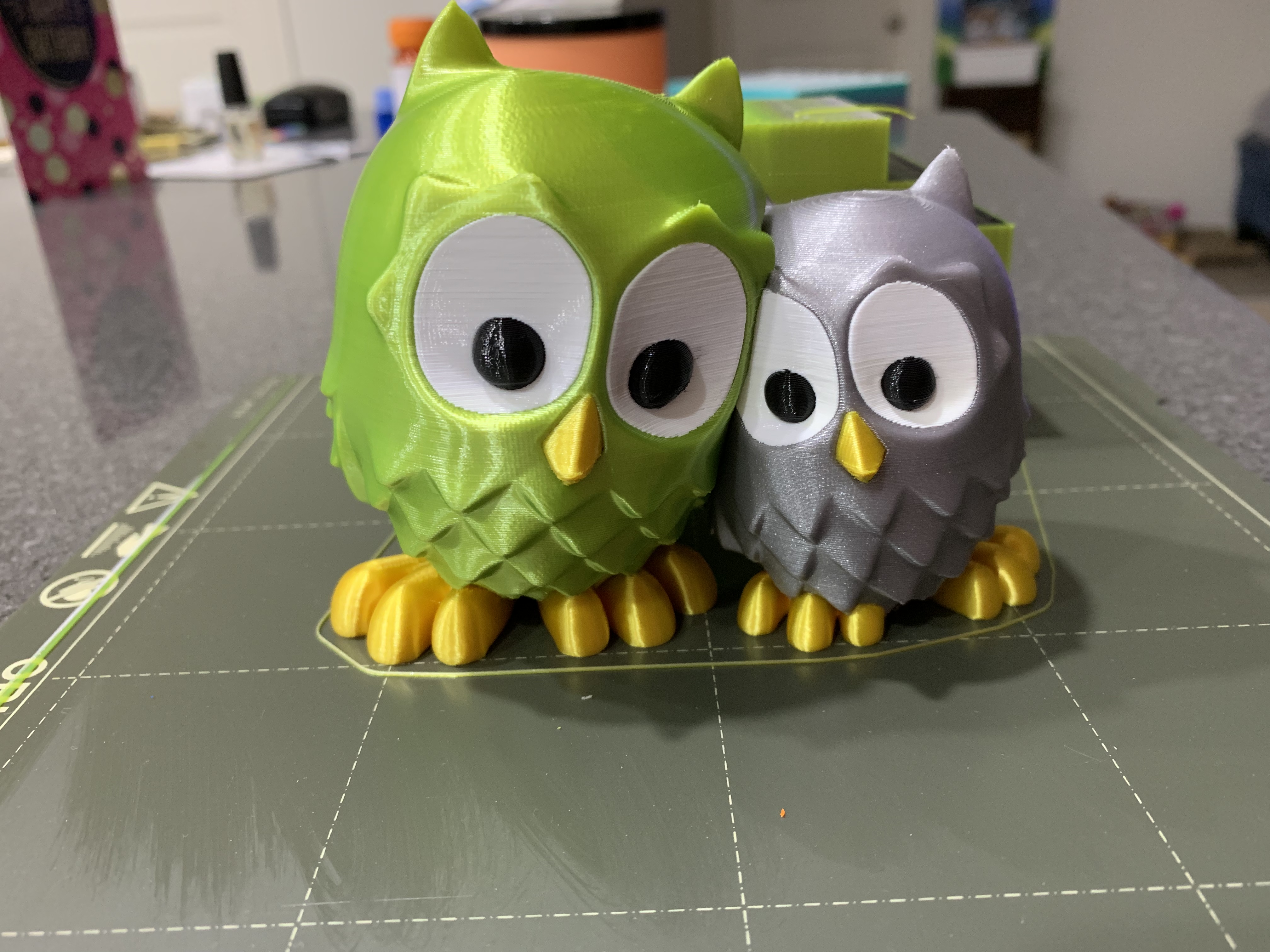

Ok, so I got a 14h print of maneki neko to work with only one intervention. I'd say that's a drastic improvement! Thanks all for listening to me whine. Simply reflashing the 1.0.6 firmware seemed to improve things.

I was using 2.4 alpha of prusa slicer I built from source and the MMU painting feature demo'd on episode 26 of the prusa live youtube show.

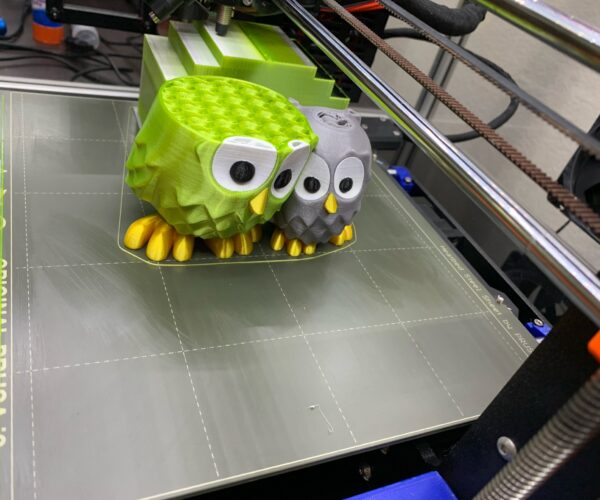

Here's the finish product. I only did 3 colors and I was a bit sloppy in the painting but I've since repainted with 5 colors and after I'm done trying the owls again I'm going to print it.

Here's the 3 color 14h version.

RE: Thanks to the Forums

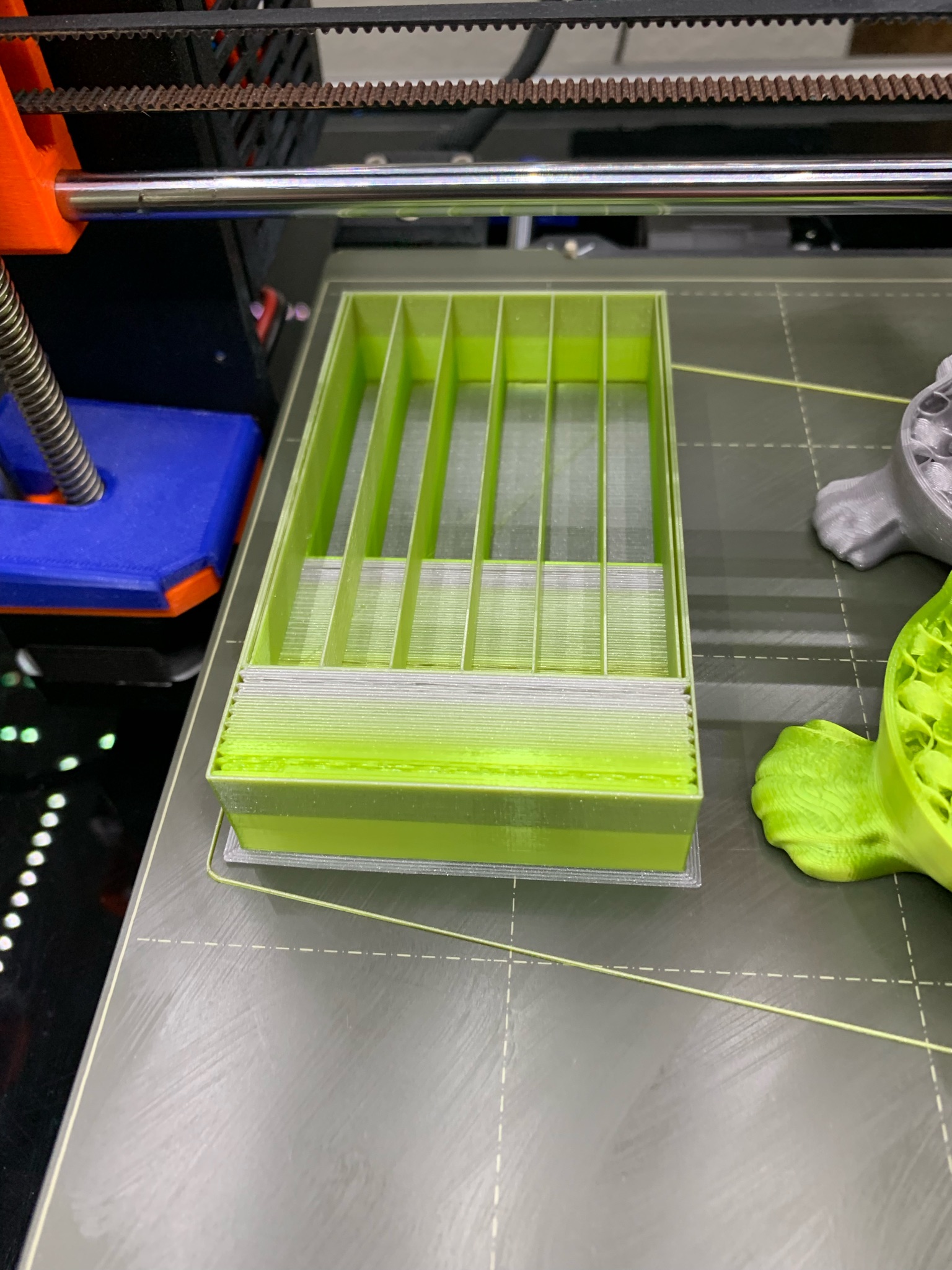

Attempt 6 of the owls underway. had a few filament load errors already, but thankfully no blobs.

RE: Thanks to the Forums

Attempt 6 of the owls underway. had a few filament load errors already, but thankfully no blobs.

At what temp are you printing. It seems Prusa lowered the temp in the filament profiles for the MMU. I only had a few load/unload errors when I used to lower temps. Changing it from 205 C back to the 220 C I used without the MMU fixed the errors for me. (for PLA)

RE: Thanks to the Forums

I'm using the prusament profiles. so far after the couple, it's been going ok. I still think I want to possibly route the filament more similar to how you have it to properly deal with the extra filament on retract. right now I have a very kludgy solution lol I hang two 608 bearings on each strand lol it's enough way to keep the filament loop drooping down instead of going off to the side etc and getting tangled with the other filament loops.

RE: Thanks to the Forums

@baklin

So prusa support came back and suggested higher temps as well. I just loaded things back up and kicked off the print. First I opened the mmu and extruder and used a toothbrush to clean the gears and compressed air to clean things out. the last attempt it was grinding a lot of filament.

I'm going to reserve judgement on this until it's been going several hours.

RE: Thanks to the Forums

So I've been working with support. It turns out I may have had my idler screw too tight on the extruder. This was after verifying the IR sensor calibration using the allen key, which was correctly calibrated. The Finda was also correctly calibrated.

I'm running attempt #8 so crossing fingers. I'll wait to be optimistic until it's been printing for a while longer.

RE: Thanks to the Forums

So I've been working with support. It turns out I may have had my idler screw too tight on the extruder. This was after verifying the IR sensor calibration using the allen key, which was correctly calibrated. The Finda was also correctly calibrated.

I'm running attempt #8 so crossing fingers. I'll wait to be optimistic until it's been printing for a while longer.

Sounds similar to my situation: my biggest problem is filament unload from the extruder, especially with one spool of PLA that brittle due to hydration. I dried all filament carefully, particularly that one roll. Now my only problem is removing filament from the MMU2S unit: the tip is too large to pull backwards. My next idea is to push the tip through the MMU2S, snip the tip, then I can pull it backwards through the MMU2S.

RE: Thanks to the Forums

@gglockner

yeah been there done that too. I have some filament dryers, but I keep them all bagged with desiccant and this being Colorado, too much humidity is never a problem lol It's the LACK of humidity. I have to take tons of precautions for static.

RE: Thanks to the Forums

I can deal with 5 interventions in 1510 filament changes. as long as they are recoverable. The most frustrating thing was the ones that weren't recoverable and frequent.