Success stories?

I was thinking of buying the MMU 2 to make live easier.

I do a lot of professional printing with multiple colors. It would be nice to automate color changes and use soliuable supports.

However i only see stories of frustrated people giving up.

Does anyone has a succes story? Will this make my live easier eventually, or is it just a difficult to use device to print stuff that has a lot of colors?

Is it just easier to manually do the color change on prints that require only one change?

I dont mind doing a lot of initial fiddeling: the most important thing is if it eventually works, it keeps working reliably.

RE: Success stories?

Remember this is a user support forum so you will see a disproportionate number of people having issues or needing help.

FWIW I've had mine since early Aug. and after a few modifications it has given me good prints with minor user intervention in some cases, usually when my filament either needed drying or wasn't dialed in right and leaving stringy tips. I'm actually about to try doing a print using PETG as support material for PLA. Should be interesting.

Changes I made over stock, and why. You don't need to do this if you don't experience the associated issue.

- Ditch the buffer and make some auto-rewind spool holders. Major QOL improvement. Many options available, I used ( https://www.thingiverse.com/thing:3338467 )

- Print an alternate selector (Stringing tips getting caught in it and jamming) https://www.thingiverse.com/thing:3688458

- Larger ID PTFE from spools to MMU (My filaments would not feed smoothly through; AB filament has a rough surface texture that can cause this.

Most of the issues people have with the MMU can be summed up as follows:

- Too much friction in filament path.

- Too much friction in filament path.

- Too much friction in filament path.

- IR sensor calibration

- Too much friction in filament path.

- See 1-5.

That said, be prepared to spend some time getting familiar with it and dialing in your filament and profiles. After that, for me it's basically been slice and go. However, it's definitely not for you if you expect it to work flawlessly on day one. There's a lot of good stuff in the kit, but technical acumen and problem solving skills must still be supplied by the user.

RE: Success stories?

Thanks! Thats helpfull.

RE: Success stories?

I second vintagepcs point, that there is a selection bias with regard to the kind of people coming to this forum: Most only visit and write, if they have issues.

I am one of those, who recently overcame all issues and is a very happy MMU2s user now. I recently wrote about the things I did to make it work for me:

I am using the dribbling PrusaSlicer mod from antimix ( https://github.com/antimix/PrusaSlicer/releases/tag/Dribbling_2.1.0) I replaced the MK2.5 heat break with the MK3 heat break from Prusa, as many people here wrote, that this is vital in order to make MK2.5+MMU2s work at all. Otherwise I just got rid of the buffer (I hate it! I use self-winding spools now) and installed this: https://www.thingiverse.com/thing:3233579 But I believe that both are not relevant for my success now, the biggest part is the dribbling and the heat break.

Friction is no issue anymore, once the filament tips are perfect. They are with the mod. IR sensor calibration is vital, but I did that once, never looked back.

I have now a very reliable printer, capable of printing without any user interventions.

RE: Success stories?

I've also gotten my MMU2 to work reasonably reliably. I can almost always complete very large prints (~2,000 filament changes) with a modest amount of operator intervention.

It does take some experience, however. You will need to intervene periodically when something trips an error condition (filament threads, sensor errors, etc.). That means you will also need some experience in figuring out how to recover and resume the print from various error conditions.

Fortunately the MMU2S seems to have evolved to the point where nearly every error is recoverable. That's much better than it used to be.

RE: Success stories?

I often thought about writing about my success experience with the MMU2S but never did.

But now that you are asking.

I got a MK3S Kit and a MMU2S several month ago and was prepared for the worst after reading about all the issues.

But until now the only issues I had was the placement of the Auto-Rewind Spool holderes. In the beginning they did not rewind as good as I hoped to and I had to supervise my MMU2S prints.

But since I got this right the MMU prints work absolutely perfect. I print a lot with different colors (mostly PLA and PETG) and I can not remember the last time I had an intervention.

Printer is completely stock except the active cooling for the extruded motor. And at the MMU Imonly changed the backplate with PTFE connectors.

I am very happy with my setup and would totally recommend it.

RE: Success stories?

If you want to hear my opinion on the basis of two MMU2s working 24/7 (just got the second up an running last night): The weak points are basically by design hence can be taken into account while building the printer. All my solutions were robust and resulted in exactly the expected behaviour (I emphasise 'my' and for me, your milage may vary).

Result: A very happy owner of these machines, MMU is great although not even needed in all cases (in these it is just used to avoid filament changes, MMU mode with single color). Both are currently happily printing with thousands of filament changes and all I can do is watch them finish their jobs... in about 3 days 😉

But: I always give this advice: The MMU setup is never plug'n'play and not the point to enter the 3D printing world. The parts needed to make the solution robust are easily printed in a few hours and the soldering/building/upgrading is done within an hour. Challenging the setup and finding the right parameters another few hours. That's it... just that you need a solid experience on 3D printers to understand what you are doing.

RE: Success stories?

Remember this is a user support forum so you will see a disproportionate number of people having issues or needing help.

FWIW I've had mine since early Aug. and after a few modifications it has given me good prints with minor user intervention in some cases, usually when my filament either needed drying or wasn't dialed in right and leaving stringy tips. I'm actually about to try doing a print using PETG as support material for PLA. Should be interesting.

Changes I made over stock, and why. You don't need to do this if you don't experience the associated issue.

- Ditch the buffer and make some auto-rewind spool holders. Major QOL improvement. Many options available, I used ( https://www.thingiverse.com/thing:3338467 )

- Print an alternate selector (Stringing tips getting caught in it and jamming) https://www.thingiverse.com/thing:3688458

- Larger ID PTFE from spools to MMU (My filaments would not feed smoothly through; AB filament has a rough surface texture that can cause this.

Most of the issues people have with the MMU can be summed up as follows:

- Too much friction in filament path.

- Too much friction in filament path.

- Too much friction in filament path.

- IR sensor calibration

- Too much friction in filament path.

- See 1-5.

That said, be prepared to spend some time getting familiar with it and dialing in your filament and profiles. After that, for me it's basically been slice and go. However, it's definitely not for you if you expect it to work flawlessly on day one. There's a lot of good stuff in the kit, but technical acumen and problem solving skills must still be supplied by the user.

Thanks, this was really interesting.

I'm having significant issues with friction in the filament path, causing extruder skipping and underextrusion.

When you say larger diameter PTFE, what ID am I looking for? It seems just about everything is 2mm ID which I think is the original spec anyway?

RE: Success stories?

I am loving the MMU. It has been a trail of tears but when it works it works well. It sat on the shelf for months at a time and then I would go through weeks of frustration and back onto the shelf until I got it to work. Definitely was not ready for public use at launch. It now prints models that I could not do without it. If you have the money and patience of a Saint with some engineering skill or if you just drink a lot and are are sadistic and love the pain buy one.

Hopefully Prusa is incorporating some of the updates but the biggest improvement was adding the magnet to the MMU selector. That fixed a majority of the failures. There are several designs out there and all good. Choose one if Prusa has not added a magnet to their design.

Selector

https://www.thingiverse.com/thing:3688458

Smaller benefit is Flag update and extruder body update. I don't know how well these worked but I think they both moved the bar a little.

Flag

https://www.prusaprinters.org/prints/3417#_ga=2.179760108.914614693.1568993008-936818007.1536362167

Extruder Body

https://www.prusaprinters.org/prints/3676#_ga=2.173451115.914614693.1568993008-936818007.1536362167

The last update is subjective. The original tubing seems to have a lot of friction. I updated all the MMU tubing to 2.0mm Capricorn tubing.

RE: Success stories?

@michael-t66

Could you please let us know what parts and upgrades you have made? I have not had one print succeed where I didn't have to babysit the machine to deal with load and unload issues.

RE: Success stories?

@mark-m30

I would suggest to try and understand why you have loading/unloading issues, if possible. I've seen people adding "upgrades" to their printer without really knowing what they want to improve. The result is usually even more disappointment.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Success stories?

@michael-t66

Could you please let us know what parts and upgrades you have made? I have not had one print succeed where I didn't have to babysit the machine to deal with load and unload issues.

Selector "Biggest bang for the buck. The selector upgrade fixed most of the loading issues" There are several versions of adding magnets to the selector. People modified it depending on which magnet they had on hand. They should all be a big inprovement.

https://www.thingiverse.com/thing:3688458

Smaller benefit is Flag update and extruder body update. I don't know how well these worked but I think they both moved the bar a little.

Flag

https://www.prusaprinters.org/prints/3417#_ga=2.179760108.914614693.1568993008-936818007.1536362167

Extruder Body

https://www.prusaprinters.org/prints/3676#_ga=2.173451115.914614693.1568993008-936818007.1536362167

The last update is subjective. The original tubing seems to have a lot of friction. I updated all the MMU tubing to 2.0mm Capricorn tubing.

RE: Success stories?

@mark-m30

I will come up with some pictures. In my earlier posts I described the modifications, all minor and easily done. Basically, the following did the trick and I have to emphasise that I built a second MMU2s printer and it was productive after a few days of fine tuning. So it can't be too far off (first one was specialised on PLA, second one is running PETG).

BTW: Your milage may vary and there are more ways for success. Mine is just one.

1. LED on the IR sensor: Lots of ways to do that. I gives you all time control of the IR sensor. You will be surprised. loading issues reduced

2. Extruder stepper cooler: PLA and MMU2s don't go along well together. It strongly depends on the amount of air flowing around your printer, not about the absolute temperature. And I triple checked this one. Active fan on the extruder, I will come up with a picture. Unloading and under extrusion gone.

3. Open selector with magnet: As I reduced grinding to a minimum and good tips with all the mods here not an absolute must, but still a bit of improvement. BTW, tips do not need to fit through everything easily behind the extruder. I cannot get mine pulled backwards through the tubes, the MMU runs anyway for thousand of changes.

4. Depends on how you see it: A new buffer or no buffer at all. It doesn't relate to the improvement question above, but the Prusa solution was the worst for me. A change in filament takes me 30 seconds without broken fingers. It has nothing to with friction as I pull my filament through various crappy PTFE tubes of over 2 meters length.

5. And I am really happy with it, but never ever had either proof or problems: Oiler and filament filter (currently I use WD40, but switch now the cheapest oil I found). It was a hint by some filament company. Your milage may vary.

Basically, these are all the relevant changes I made. What I can also give you as a hint: I run the standard profiles 5 °C higher and PETG with an extrusion rate of 0.95. I had ramming moves +1 for a time, but forgot about it over time and I am good with the standard right now.

As I said I will probably upload some pictures tomorrow to give the general idea. All the modifications are printed in a few hours and the setup takes maybe two hours till you are good. Currently both are basically running a week in a row with maybe a hiccup every 2-4 days. So, no complains at all.

RE: Success stories?

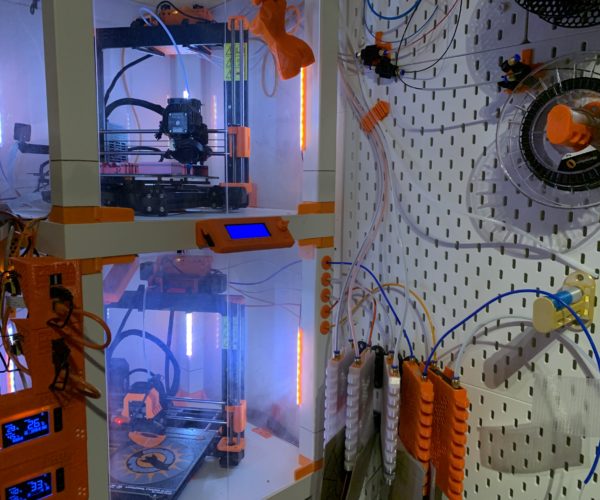

Full setup (polymer boxes on top)

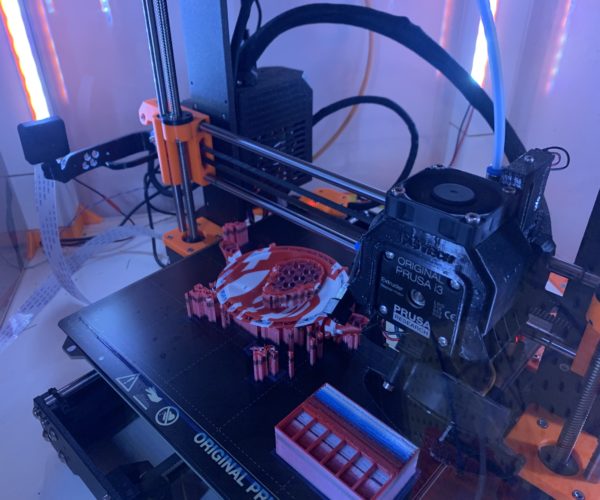

PETG MMU2s with active cooler (probably not needed for PETG) and nasty IR sensor LED

Same for PLA

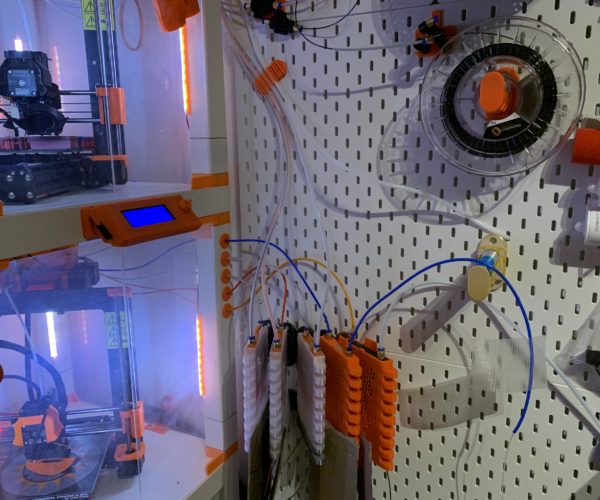

Open selector

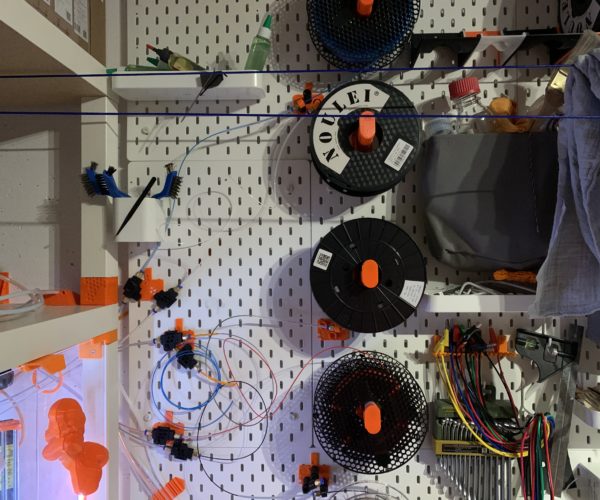

Simplest buffer solution with oiler

Stephen Boyds MKVII buffer, skirts are currently being printed to get rid of the card board

RE: Success stories?

Addition: If anyone wants to have the stls or the links I am willing to share them

RE: Success stories?

@michael-t66

Thanks for the info and the pictures. Can you explain what the magnet in the new selector does? There isn't one in the now (is there? don't remember putting one in).

RE: Success stories?

The magnet in the selector pulls the ball bearing down. Sometimes the filament has a little string at the end that keeps the ball bearing from falling down and the sensor thinks the the filament is still there so it pulls the filament out too far so the next time it goes to use the filament it cannot load it. Updating the Selector with the magnet was the single most useful upgrade I did.

RE: Success stories?

@mikicab

Right. The magnet should be standard as well as an open idler. I will soon test my modified pulley body so that all the garbage falls down onto the bed instead of piling up in the way of the idler. Pretty simple upgrade and my estimation is that this will not cause other troubles. I already designed it, just need to print and test it.