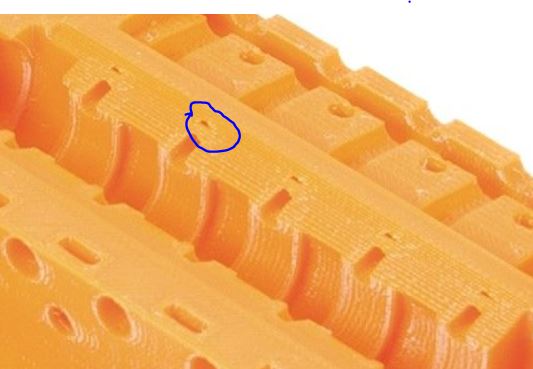

Small slots in MMU chassis catch the filament, preventing the filament from entering pulley body cavity

I'm repeatedly having trouble loading filament because the filament end seems to jam on the little slots in the MMU pulley body.

I trim the filament at the recommended angle, but invariably, the remaining pointy tip finds that little slot, and I can't push the filament the rest of way in. I've taken to using pliers to crush the end of the filament into a cone, and that does not hang up as much.

Am I missing something?

RE: Small slots in MMU chassis catch the filament, preventing the filament from entering pulley body cavity

I personally found it a bit difficult to insert the PTFE tubing far enough into the slots. Due to this, there was a bit of a gap between the end of the tubing and the small hole that the filament needed to be held in. This gap, coupled with that hole you pointed out (that is the start of the smaller OD position - the filament path) causes the hangup that you noted.

To fix this jamming on inserting filament, I opened up the PTFE slots a bit. A 5/32 drill bit is very similar to the OD of the PTFE tubing (3.96mm ID for a 4.00mm OD). By boring out the hole just a little bit, the PTFE tubing could be inserted the proper distance to eliminate this hangup.

If you do this, be careful! Do this by not using a drill. Use the bit, not the drill. Either a hand chuck or a high friction cloth would allow you to hold the drill bit to remove some of the material. If you get too aggressive with the modification, you can risk ruining the plastic part! Understand your objective, do not push the drill but in too far, and know the depth you want to remove material to ahead of time and it will work for you as it did for me.