Progress in printing PETG with the MMU2

Since I installed the MMU2, I try to find out the settings to print PETG without issues, I had to deal with many print failures due to various reasons, first of all was the unreliable filament load, second was the long long strings produced by PETG filament, third the print settings in Slic3rPE, and the last is sometimes the filament tangling with my spooI holder setup, but I didn't it solve yet.

I solve the filament loading first, I did the 5 individual filament calibration, but instead of aligning the filament to the middle of the gears, I align it to the PTFE tube, I change also the Extra loading distance value in Slic3rPE (Printer setting--->MMU settings), setting the value to -5, instead of -13.

The filament is pushed further and is correctly caugth by the extruder gears, I tightened the idler cover a little bit more to prevent filament slip, I didn't detect any filament grinding.

I had also some print failures due to a pack of strings trapped in the filament sensor chamber and clogging the pass when grabbed by the filament.

To reduce stringing I've tried printing at lower temperatures, but I didn't notice any improvement, it's too random, sometimes I had no strings and sometime short string and sometime very long strings.

So as the filament sensor is actually disabled I printed a new extruder body with all the filament pass calibrated to 4.2mm and inserted a PTFE tube from the filament sensor cover to the Bondtech gears, it's a temporary solution but it solved the accumulation of strings.

I played also with the filament setting in Slic3r, and set ramming time to 4 seconds.

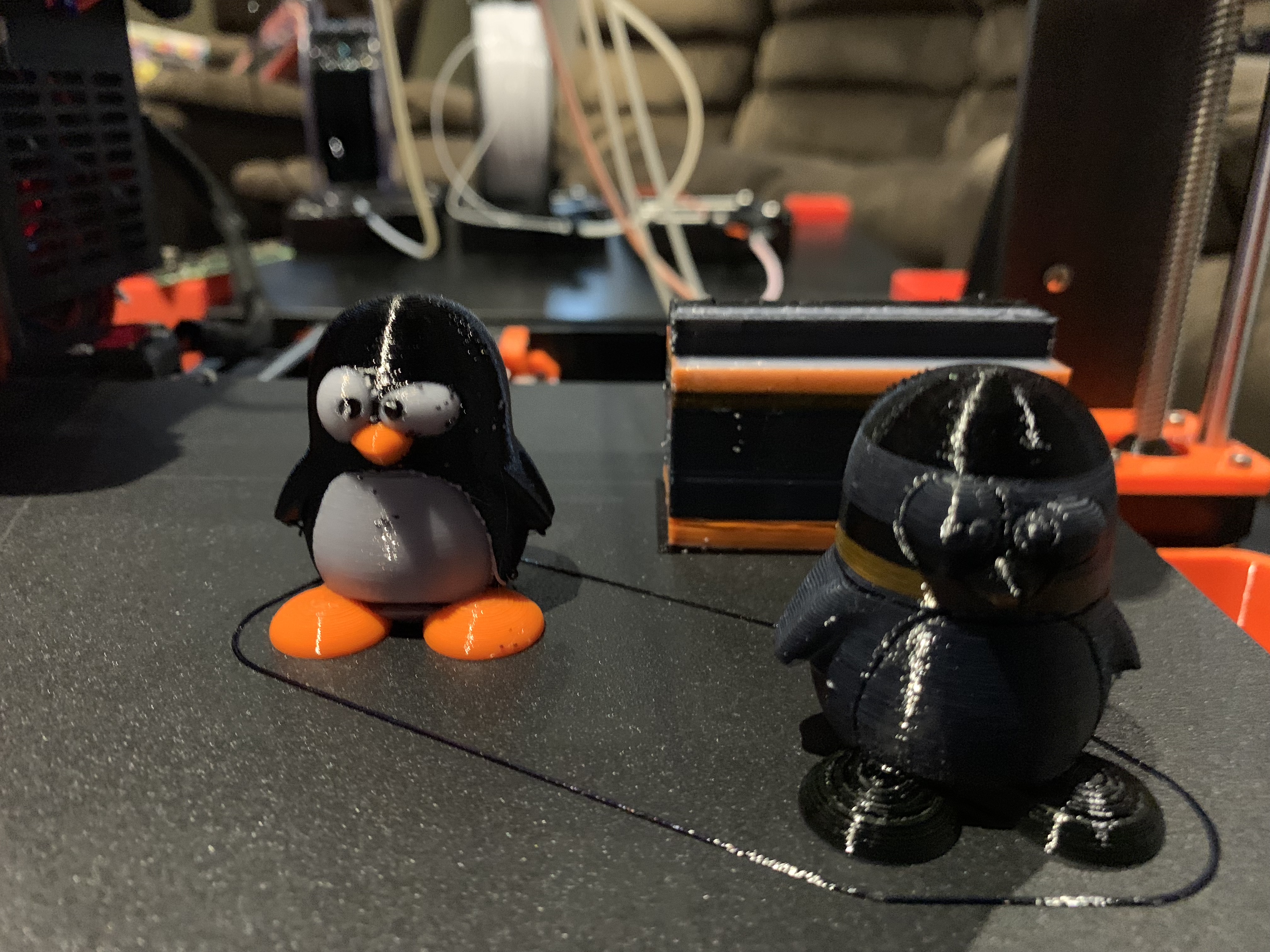

My last print in PETG is Gustav the turtle in 4 colors, I used 3 different filament brand, unfortunatly I had two layers skip due to filament tangle issues, I saw too late the first tangle with the Prusa filament to be able to fix it, I supposed the second during the night was the same, I had several time this issue with the FormFutura filament.

Orange Prusa PETG

Pearl blue FormFutura HD Glass

Silver and black DailyFil PETG

Sliced with Slic3rPE 1.41.1-rc

3 perimeters

Giroid infill 20%

Common settings for all filaments, 220° print temp 75° heatbed

Purge into infill

304 tool change

10h30 printing time

MK4/MMU3 - VORON 2.4 350 Stealthburner

Re: Progress in printing PETG with the MMU2

I like the idea of one tube. I think they use the lower tube to do some shaping, and where it is may matter some amount as well.

I get the same thing with PET and TPU - I don't eliminate strings, I just get prints that happen to work in spite of them.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Progress in printing PETG with the MMU2

I had good success setting the purge to 4.5s and the number of cooling moves to 4. Takes forever but I get reliable tips without strings.

Re: Progress in printing PETG with the MMU2

Where do you find those settings?

Here is my first attempt. I have a couple of layers missing, no idea why as it never got tangled. I did however have to tend to the MMU due to it not feeding properly, either because if stringing or something else...

I still need to tweak it so that it doesn't have all the little blobs through it (advise would be fantastic!)

My wipe model interns of print quality turned out way nicer that the actual intended model. :/

Sorry for the blurry photos

Re: Progress in printing PETG with the MMU2

the blobs are interesting to me. I print exclusively in PETG, and had lots of large blobs that would accumulate under the hotend and then randomly deposit on the model. I solved it by adding a hotend sock (silicone boot).

have you watched the print to see where the blobs are coming from?

Re: Progress in printing PETG with the MMU2

Thanks for your reply. I might give sock a go. I have tried to print something else since then using red PETG but unfortunately I can't even get past the wipe tower.. It doesn't stick and keeps getting collected by the nozzle and thus lifting the first layer of the wipe tower. Additionally the speed at which the tower prints is way too fast, it also looks like the extrusion is less for the tower and the supports. 🙁

Re: Progress in printing PETG with the MMU2

So after some mistakes on my part I was able to print OK with the MMU2 last night with PETG in Orange, Black, and Transparent Red.

My advice would be to make sure your first layer is perfect. Everyone says that, and it sounds like a cope out, but it really does matter. I actually use a microscope to examine the layer and make fine adjustments.

Bed has to be clean. I use IPA on every print. Things stick very well unless my Z is too high. then nothing sticks at all.

Also, if you are using slicer, run the config wizard and generate the recommended MMU2 settings I had no end of problems until I did this. I thought I knew better and tried to create my own settings, which cost me around 4 hours of aggravation and never worked.

keep trying.

Re: Progress in printing PETG with the MMU2

Thanks, my print works fine with no wipe tower. Its just the tower that introduces problems as it prints way to fast and doesn't appear to extrude enough filament (it certainly isn't the same as the first layer on a single filament print).

Re: Progress in printing PETG with the MMU2

ah, i see. I did have trouble when the extruder moved from the tower to the print. The filament just wasnt extruding for the first 1/2 inch or so. I have been playing with the 'extra length on restart' option to push a little more filament out when it moves from the tower to the part.

I will post again when and if it makes a difference.

Re: Progress in printing PETG with the MMU2

Since my first post I have made real progress with PET prints,

For the moment with the filament sensor disable It's just impossible to acheive 100% sucessfull prints, and with highly stringing material it's much worse.

Dispite I raised my ratio of successfull prints in PET, now I can print 6 or 10 hours objects without any layer skip, just sometimes a MMU unload failure (one or two per print not more) due to strings stucked under the FINDA ball, but easily manageable.

As it is almost impossible to prevent PET stringing, I understand we must live with, and the filament cutter seems to me to be more like a concept rather than a reliable solution.

This is what I did to increase my ratio of successfull prints, in first what had the more impact on my prints.

Different FINDA adjustment approach, instead of raising the FINDA after contact with the ball, I searched the ball detection limit.

To do that, with the printer turned on and bowden tube removed, I pulled out the FINDA, through the menu selected filament load, (whatever the filament you load) and than lowered the FINDA step by step until the filament goes backwards, tighten it and gave one quarter turn more to the FINDA. This ensures maximum room under the ball and makes the FINDA less sensitive to strings.

I replaced the orange bowden tube by a transparent pneumatic hose with 2.5 internal diameter,

rebore the two festo coupling to 2.5, as well as the filament pass in the selector, the five short PTFE tubes in the front holder, and the fist part of the PTFE tubes clamped in the rear holder.

I also rebored to 2.5 the PTFE tube I inserted in the reprinted extuder body (see my first post) https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f53/progress-in-printing-petg-with-the-mmu2-t25417.html

Except specific filament settings I did the 5 individual filament calibration, but instead of aligning the filament to the middle of the gears, I align it to the extruder PTFE tube, I change also the Extra loading distance value in Slic3rPE (Printer setting--->MMU settings), setting the value to -8.

MK4/MMU3 - VORON 2.4 350 Stealthburner

Re: Progress in printing PETG with the MMU2

the cutter is too far away from either the entrance to the selector or the exit from the pulleys to do anything. the knife needs to be flush up to either side so it gets leverage to actually cut the filament. all it does is kink it 90 degrees and then it jams between the knife and the selector bench. strings just go underneath it then any stragglers get stuck in the FINDA and get rerammed (maybe) down into the extruder by the next filament otherwise lift the ball and give a false positive.

PETG is just so stringy it may never work 100%, same with the softer TPU(below 80 shore) and Nylon those all string by nature and if you bring the temps down to make the strings behave then the temperature is much to low for proper layer bonding.

if there was a slot 6 for the spools, that could be setup as a FINDA Ram. after F1 is unloaded the selector goes to F6 and a ram on a solenoid cleans out the finda(would have to also move the orange tube in and out of the way.(junk ejector) with a cleaned finda it then goes to the next Filament.

hum gave me a stupid idea.

Imagine if there was a air connection to the selector each time the MMU triggered an unload a Blast of air would come from in front of the ball and blast a clog back to the bench. to ensure the ball could drop freely.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Progress in printing PETG with the MMU2

I'm also getting very random strings with petg. Every time I think I have them gone, one color or another will string and eventually get rammed down into the print head causing a jam. I think if the movement portion of the optical filament sensor was working, the jam would at least be detected and allow some intervention. However, what I wind up hearing is a clicking extruder from the other room and by the time I get to the printer, half a layer has been skipped.

I've gotten one 12-hour petg print by sitting by the printer and clipping the strings off the end of each filament between loads. I was hoping to print a bunch of multi-color outdoor plaques in petg with the MMU. I've done a few by just switching colors on the Z axis manually before I got the MMU, but the multi-color embedded text sure looks nicer. For now, I think I'll look for some other outdoor filament options that are less stringy.

Along the lines of completely reworking the MMU for strings, I’m picturing some blade or hot wire that would come down and cut off the stings, maybe from all 5 PTFE tubes at the same time. This might reduce the force required if it was either hot or had a hard surface to pinch against to cut everything off. I've seen some of the strings that were thin enough that the FINDA thought that the filament was unloaded, however even when the selector moved to the next filament, the string was still down the primary tube. This caused all kinds of neat failures as it sometimes tried to pull the last filament out of its tube at the same time it pushed in the new one. Something that thin and flexible is not going to get cut by dragging even the sharpest razor blade past the string without something holding both ends. You’re also going to have to move the selector to some home position that would pull any extremely long stings completely out of the primary tube.

I3 MK3 MMU 2.0.

Re: Progress in printing PETG with the MMU2

I'm also getting very random strings with petg.

which manufacturer are you using PETG?

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Progress in printing PETG with the MMU2

I'm also getting very random strings with petg.

which manufacturer are you using PETG?

Matterhackers build and Amazon basics primarily.

I3 MK3 MMU 2.0.