RE: MMU2S filament tips on unload

And yes I agree you have to mod the crap out of it to get is somewhat reliable. But hey that's part of the fun.

RE: MMU2S filament tips on unload

I appreciate the attempt to help. I really do. Your mod could be the magic solution.

But, I just don't have the emotional energy to even attempt another mod. I've tried so many suggestions that work for other people, but don't work for me.

This has been the most frustrating 3D printing issue I've dealt with, and I've been doing this for 8 years with 5 printers.

RE: MMU2S filament tips on unload

Don't give up it's actualy quite simpel. Make sure you have an as much wide channel to your hotend from your filament. That means different ptfe tubing and the passthrough fitting mods. The you have to make sure the bondtech gears stay cool enough not to mess with your filament. i found this out beceause i would have the first 2-3 hours of printing not many issues but after this time i would get stringing and tip problems. And i found out the extruder got verry warm.

RE: MMU2S filament tips on unload

Its definitely not a trouble free tool (as the MK3 itself is). But having a separate support material or printing some small 2 or 3 Color prints is worth the effort.

On large prints with nearly 1000 tool changes it happens to me also that I Need to interact a couple of times. But even then, the result is worth the Trouble.

I would not go without it.

RE: MMU2S filament tips on unload

And yes I agree you have to mod the crap out of it to get is somewhat reliable. But hey that's part of the fun.

Not really. There are a lot of people out there running their units stock. But to understand the issues and fix them by adjusting the right things takes some time.

I fully understand people giving up especially if they are following the MOD trail. There is no magic solution, just a complex machine.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: MMU2S filament tips on unload

Running it stock works. But only after verry carefull filament tuning. Since I run all kinds of filaments and brands that was not what i wanted. I want a reliable setup that doesn't need much of tuning. To achieve that i did the following mods:

-larger id 3mm ptfe to the extruder and the 5 small pipes in mmu id 2.5mm, and filament loading tubes also id 2.5mm.

-Cooling fan on the mk3s extruder motor,

-Updated mmu parts from 3.9.0rc (3 items)

-Updated to 3.9.0rc

-Updated m10 passthrough fitting on the selector

-Updated m10 passthrough fittings on the back op the unit to slide in the 5 ptfe

this makes sure you have as little obstruction as possible in the filament path to the extruder.

That's what works for me. I am forcing nobody to do this, just trying to help.

RE: MMU2S filament tips on unload

@gnat

Filament Settings > Advanced > Toolchange parameters with single extruder MM printers > Unloading speed at the start = 120mm/s

This does not appear to be an option with PrusaSlicer 2.2.0, or am I missing something?

DJ

RE: MMU2S filament tips on unload

Are you using Prusa Slicer in 'Expert' mode!?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: MMU2S filament tips on unload

Are you using Prusa Slicer in 'Expert' mode!?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: MMU2S filament tips on unload

@joantabb

Thanks Joan, that did it!

I missed that part of the instruction and didn't think to check it.

DJ

RE: MMU2S filament tips on unload

:--D

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: MMU2S filament tips on unload

@mike-zoll

I think the video you refer to is:

RE: MMU2S filament tips on unload

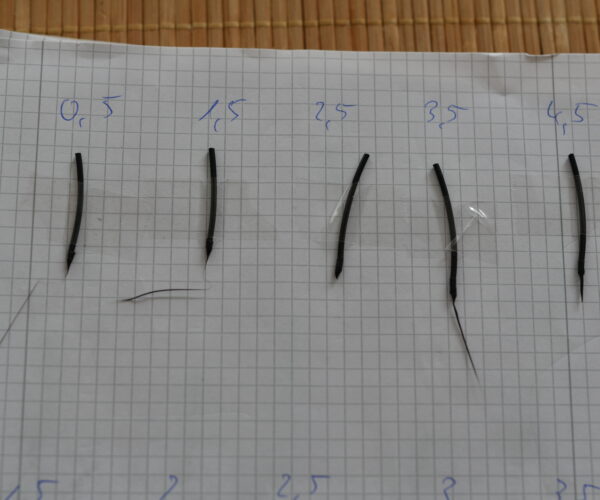

some Pictures of my tests. Black Filament; no specific stringing Problem:

you see the sweet spot at 2,5s.

a repeat with smaller increments:

you can verify 2,5s with a slight tendency to 2s. I prefer shorter ramming. If you look closer you see that the tip length is also shorter which is good.

Next material green with a high tendency to stringing (in regular print):

you can see a very high tendency for stringing at longer ramming time (very suprising). Sweet spot seems arround 1.5s with still a very thin stringing - but wich is tolerable if you have tubes with larger ID (make sure that you replace not just the long tube from the selector to the Extruder but also all short tubes inside the MMU2.

Btw: my selector:

https://www.thingiverse.com/thing:3528314

Hi there, apologies for the slightly dumb question, but what process did you go through to do this test?

RE: MMU2S filament tips on unload

Running it stock works. But only after verry carefull filament tuning. Since I run all kinds of filaments and brands that was not what i wanted. I want a reliable setup that doesn't need much of tuning. To achieve that i did the following mods:

-larger id 3mm ptfe to the extruder and the 5 small pipes in mmu id 2.5mm, and filament loading tubes also id 2.5mm.

-Cooling fan on the mk3s extruder motor,

-Updated mmu parts from 3.9.0rc (3 items)

-Updated to 3.9.0rc

-Updated m10 passthrough fitting on the selector

-Updated m10 passthrough fittings on the back op the unit to slide in the 5 ptfethis makes sure you have as little obstruction as possible in the filament path to the extruder.

That's what works for me. I am forcing nobody to do this, just trying to help.

"-larger id 3mm ptfe to the extruder and the 5 small pipes in mmu id 2.5mm, and filament loading tubes also id 2.5mm."

Hi Ruben, what drives the choice of 3mm between MMU/extruder, but 2.5mm elsewhere? Do you think there'd be an issue using 3mm everywhere?

RE: MMU2S filament tips on unload

@roger-g

no dump questions - only non-satisfying answers:-)

I created a test structure with 5 elements (simple cubes) and assigned every cube a different filament. On the filament settings I changed the ramming time (nothing else). You can load all slots of the MMU with the same filament (1m length) and let it run. I fooled the FINDA sensor with a piece of filament and did the load and unload manually.

RE: MMU2S filament tips on unload

I still had some issue with loading. This mod fixes that too.

https://www.prusaprinters.org/prints/3676-mmu2s-extruder-mod-feeds-almost-any-tip-no-jams-fo/related

RE: MMU2S filament tips on unload

I still had some issue with loading. This mod fixes that too.

https://www.prusaprinters.org/prints/3676-mmu2s-extruder-mod-feeds-almost-any-tip-no-jams-fo/related

Thanks, I've printed those parts, ready for when I can be bothered to rebuild the extruder!

Regarding the "5 small pipes in mmu id 2.5mm, and filament loading tubes also id 2.5mm", is there any reason not to go with 3mm ID tube there as well? I have enough 3mm ID tube to replace everything, but your post got me wondering if 2.5mm ID was better for those locations.

RE: MMU2S filament tips on unload

Hi 3mm id gets verry thin so will wil easily fold the tubing. so i only use 3 for the extruder.

Tips on stopping filament retraction on MMU2S

Hi folks,

- Have latest firmware for MMU2S and MK2.5S printer (3.9.0).

- Have replaced selector with magnet selector ( https://www.thingiverse.com/thing:3688458).

- Have replaced old extruder housing for for new extruder housing allowing PTFE pass-through direct to drive gear (don't have link yet, but its the one that retains the 'tower' for the IR sensor).

- I have 2.0mm ID/4.0mm OD - PTFE for selector to extruder housing ( https://amzn.to/3k5Xk1r).

- PTFE elsewhere is probably standard diameter (in MMU2S housing and going to filament spools).

- Due to different PTFE length from selector to extruder i ran the PTFE length firmware manual update thingy for all filaments.

- Can confirm that all 'filament straight to extruder' prints are successful.

Please see link to video as follows showing at .18 the filament being retracted > https://photos.app.goo.gl/XeqDpzbTEzFReYn37

Please see photo linked as follows showing slight bulge on filament tips > https://photos.app.goo.gl/fNin59YdXYSXEUwt7

What else to do to stop retraction of filament (which usually happens half way through a print - always successful at the start).

Suspicions are - wromg size PTFE in heat chamber? Standard PTFE ID too thin in MMU2S housing body?

Not too sure. All help appreciated!

Cheers,

Michael

RE: MMU2S filament tips on unload

Can somebody tell me why there is not a tool from Prusa to tune the tips? As everybody noticed that it depends on the filament and we should have different settings for each of them, why there is not a toll to set it somehow set it up? Something that you have a script to set different speed, time unload, and load and cut the tips and compare them after? Any thoughts about it? Whatever from Prusa? It seems that they simply gave up MMU2 as previous version of MMU1...